Imperial solid carbide spilt point drills

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000 pcs/month |

| Supply Ability: | 5000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO9000 |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Hongkong |

Imperial solid carbide spilt point drills

The original method of manufacture about twist drills was to cut two grooves in opposite sides of a round bar, then to twist the bar (giving the tool its name) to produce the helical flutes. Nowadays, the drill bit is usually made by rotating the bar while moving it past a grinding wheel to cut the flutes in the same manner as cutting helical gears.

Most drill bits for consumer use have straight shanks. For heavy duty drilling in industry, bits with tapered shanks are sometimes used. Other types of shank used include hex-shaped, and various proprietary quick release systems.

OPT carbide twist drill has high speed and long life than other similar products.

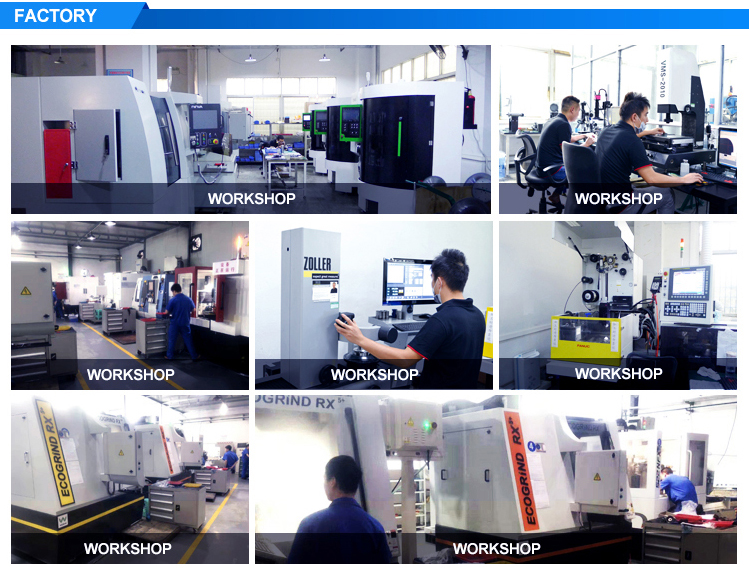

We have our own workshop and produce the PCD, CBN and Carbide cutting tools.

Application area:

Drilling can be done by almost any machining tool that is capable of cutting, including drilling lathes, milling machines and drill presses.

Advantages:

1.The unique drill point makes cast iron more light and steady.

2. Blade passivation ,impact resistance , anti collapse ,and life increase.

3. The chip cutting trough has large space and fast chip removal , which is suitable for high-passed and large feed cutting.

Product Show:

Releated Products:

PCD Reamer>>

PCD Reamer>>

Taps and Thread Milling Cutter>>

Taps and Thread Milling Cutter>>

Material:

Tungsten Carbide

Packaging:

Be

packed with plastic case or box.

Quality control:

We have dedicated team of quality control and art equipment to keep good and stable performance for our products.

OEM/ODM Service:

Customization cutting tools is an easy process when partnering with OPT. From drawing to tooling completion takes no longer than 4 weeks. With a sample profile, a CAD file or a dimensioned sketch, we design precision profile tooling with safety, accuracy, exceptional performance and our customer`s complete satisfaction in mind.

Our Service:

- sample is available for testing before ordering

- Customer oriented

- After sale replace service

- Full stock available for urgent demands

About us:

We are the manufacturer of PCD, CBN and Carbide cutting tools in China.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Reamers, PCD Forming tools, PCD Woodworking Tools, Carbide Taps, Carbide Drills and many more.

If you encounter problems such as high-speed, high precision requirements, low tool life and so on in the processing, you may contact us to recommend appropriate design for you, we can provide customization per your drawing.