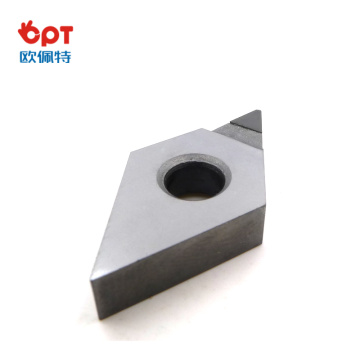

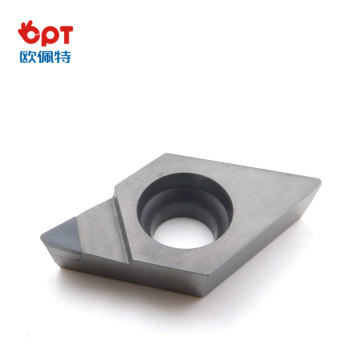

Carbide forming tools for watch

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/month |

| Supply Ability: | 10000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

Carbide forming tools for watch

The case is classified according to the material into non-metal (plastic, ceramic, etc.) and metal (stainless steel; titanium, white titanium; copper, aluminum and other alloys; tungsten steel and precious metal series, etc.). Stainless steel case, titanium case. The case is classified according to its structure and processing method: single round shell, single shell shell, dead loop shell, loop shell, sleeve shell, etc. Case parts introduction (with pictures): Case (single shell, inner shell); bezel (single and multi-turn); bottom (meter bottom, sub-bottom, bottom, screw bottom) Case accessories (with picture): I-RING (circle, Glass), O-RING (bottom, circle), bar, tube, press, tube, glass, slingshot, octagonal, elastic, marble, spring, inner circle, literal, inner cover, decoration Nail, ear, teeth, branch, face, face, bottom.

The basic process flow of the table cutting production and processing:

1. The basic process of round shell cutting is

Open thick (coarse and coarse), open material (first, second and third grade silk, tooth position, waterproof pit, bottom flat), drill bite - inner oblique position - drill bit - light ear Bottom - belt draping - car grinding teeth smashing position - drilling deafness - car glass position, line position, inside reflection - scraping phoenix - fine car ear surface - ceramic knife action (shell surface , circle oblique, introverted).

2. The basic process of square shell (steel fine embryo) cutting:

Fighting the scorpion, the inner oblique position, the nail position, the glutinous rice position (screw ) scraping the phoenix - the drill ear licking.

3. The basic process of rotary cutting:

Open rough, flat bottom, sub-port, inner car bottom and car apron pit and sub-mouth high-sweeping trousers, foreign yuan cloak, rough car surface flat, face pit

4. The basic process of decorative circle cutting:

Open rough (rent in the middle, flat) - material opening (car bottom , quasi-mouth) - rough R position, rough surface flat - thick and young outer yuan - fine car surface R position or ceramic knife action.

5. The basic process of functional circle cutting:

Open rough (rough middle, rough flat, thick outer) fine, sub-port, intro, low R position, rough flat glass position, line fine car surface R position or ceramic knife action.

6. Basic process of bottom cutting:

Opening material (outside vehicle, bottom level, bottom slope), inside the car, inner mooring, full height tooth position, anti-level position, waterproof pit car grinding teeth.

7. Basic process of rice bottom cutting:

Avoid the bar - play the rice - gong introduce the angle - go to the cloak.

ABOUT US :

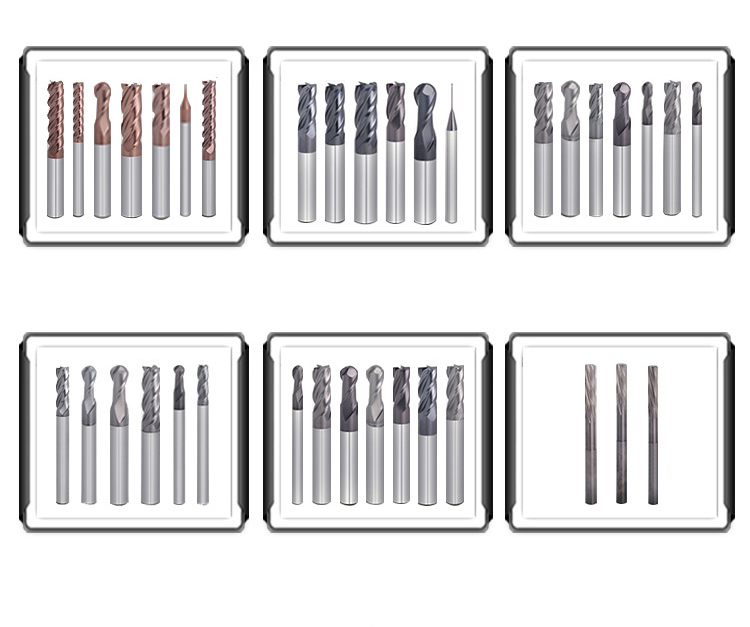

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.