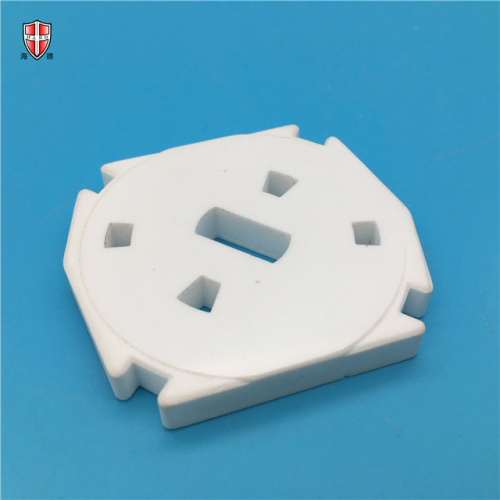

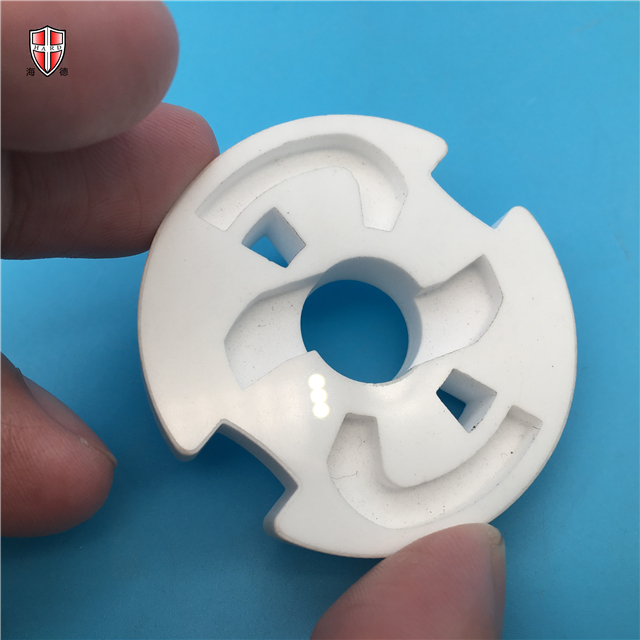

custom alumina ceramic switch faucet valve disc plate

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

99% alumina long ceramic tube pipe sleeve

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

In refractory castables, the amount of refractory aggregate is generally 63% to 73%, and the amount of refractory powder is 15% to 37%. For refractory castables, coarse aggregates with a particle size greater than 5mm are generally used; granules ranging from 5 to 0.088 are called fine aggregates. The critical grain size of the aggregate is determined according to different construction methods. Generally, it is 10mm or 15mm. For large structures such as blast furnace foundation pier and ladle castable, 20mm or 25mm particles can be used. In addition, the critical diameter of the refractory aggregate is also different due to different construction methods. At present, the critical diameter of the refractory aggregate tends to increase. It should be noted that when formulating the refractory castable, the gradation of the refractory aggregate particles should comply with The technical requirements in the table, even if the powder is used, it should be screened to meet its requirements before it can be used. The refractory powder is the matrix material of the amorphous refractory material, its grade should be higher than or equivalent to the refractory aggregate, and the fineness requirement is less than 0.09mm or 0.088mm should be greater than 85%. For ultrafine powder, more than 80% should be less than 5μm.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryDensity: 3.9g/cm3

Alumina Content: 96% 99% 99.5%

Gas permeability: 0

Water Absorption: 0

MONS' Hardness: 82

Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²)

Flexural Strength(20°C): 330Mpa

Compressive Strength(20°C): 2000Mpa

Fracture Toughness (20°C): 4 MPam1/2

Thermal Conductivity(20°C): 27.5W(m.K)

Thermal Expansion Coefficient: 7.6 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.