Powerful automatic spraying machine

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CIF, EXW, FCA

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 600 |

| Supply Ability: | 50 |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CIF,EXW,FCA |

| Certificate: | CE ISO |

| Transportation: | Ocean,Land |

| Port: | Shenzhen |

product description

Product Details:Powerful automatic spraying machine

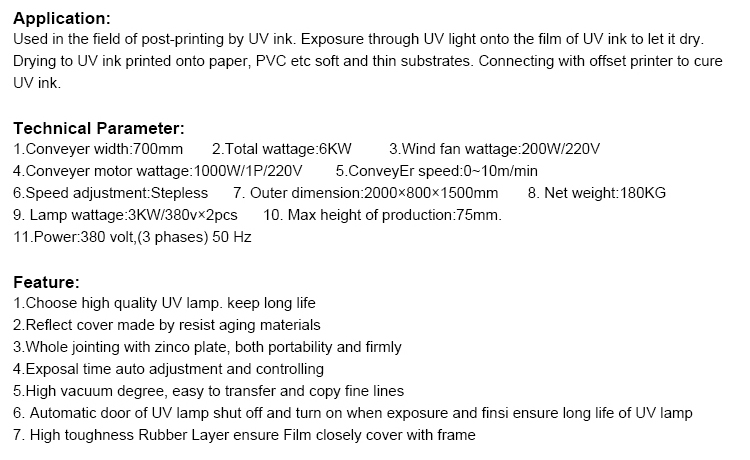

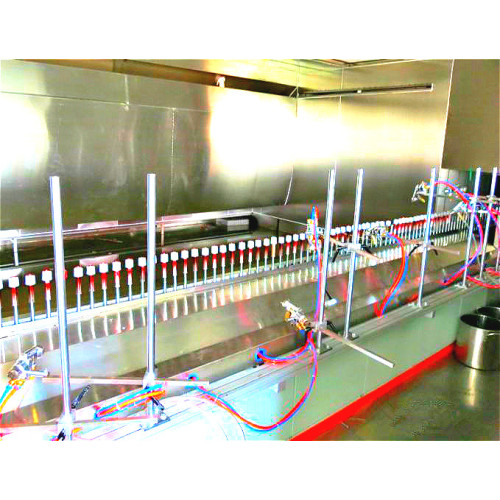

1. All the equipment on the market is a "reciprocating fuel injector" which an only spray back and forth. The disadvantage is that the sprayed product has uneven coating thickness, wastes oil, and cannot spray to dead ends. The company's product is 360-degree high-speed rotating fuel injection to ensure that there is no dead angle in the fuel injection and save paint.

2. The equipment on the market can only be sprayed for some simple workpieces, and has no versatility. It is difficult to accept orders for complex workpieces, or it can only be manually sprayed. The equipment can only be displayed. The company's products are completely Can spray processing on any product.

3. Simple operation, no need for skilled fuel injectors, new employees can operate

4. The model is small and exquisite, the dual oil gun 360 degrees 400 rpm high-speed rotating spray technology, one-time spray covering 5 surfaces, saving about 35% of the paint

5. Hand-painting (hand-painted function) fool-like teaching, infrared sensor to spray area, automatic memory spraying route,

6. Independent teaching function for AB surface, no requirement for mold, no worry about mold error

7. Human-machine integrated control system, one mold with multiple workpieces

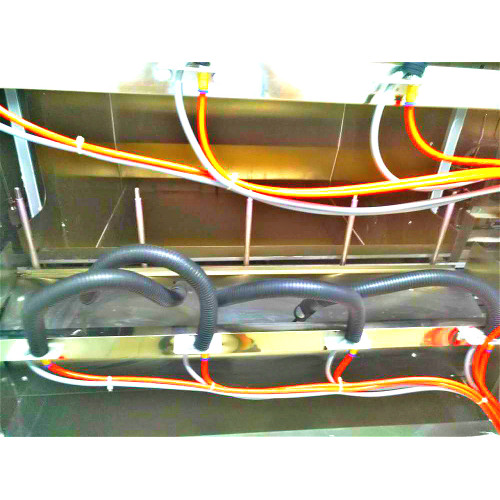

8. Safe, the whole machine is fully enclosed to operate, workers cannot touch paint, and cannot breathe harmful gases

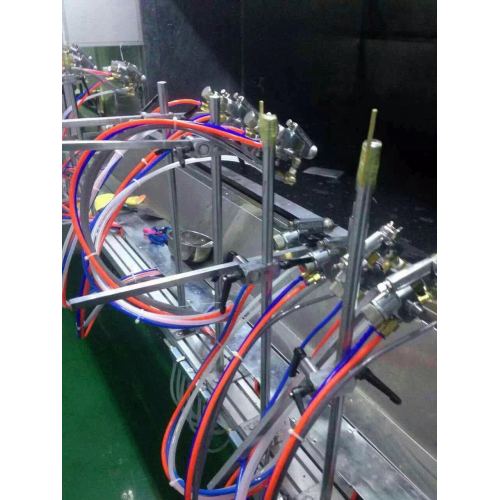

9. Environmental protection, super large oil and dust adsorption water curtain, fully enclosed operation

10. Set a reasonable mold washing time; the production volume can be controlled.

11. The parameters of N products can be stored, and they can be stored via U disk;

12. All-stainless steel structure, durable, and will not loosen like the aluminum frame structure, which is connected by screws, causing the fuel injection to run out of position.

13. Energy saving: 0.55KW of electricity per hour