Metal CNC vertical machine center with high efficiency VMC-650L

- Delivery Time:

- 35 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Product Description Main Features (1) X,Y axis are linear slideways,Z axis is box way.

(2) Coulping,Spindle bearing,spindle,ball screw,linear slide way,tool magazine,unclamping cylinder and other key parts are all imported from Germany,Japan and Taiwan top brand to ensure high quality and high precision.

(3) Modular cofiguration,can provide customized options to meet different customers processing needs:Spindle water coolant,Gear type spindle-case,10000-15000 rpm/min direct connection spindle.

(4) Suitable for various small to medium parts processing,with faster feed speed,and high rigidity cutting.

Accessories Standard Accessories 1. Fanuc /Mitsubishi Controller system 2. Full enclosed cover 3. Spindle encoder position system 4.Three Inner encoder feedback system 5. Auto lubrication system 6. Pneumatic system 7. RS232 Interface 8. Operation unit 9.Warming light 10. Working light 11. Tool and tool box Optional Accessories 1. Siemens Controller or Other Controller 2. Spindle oil coolant 3. Umbrella type tool magazine 4. Arm type tool magazine 5. Screw type auto conveyor 6. Chain type auto conveyor 7. 4 axis rotary table 8. Through spindle water coolant 9. Ring spray spindle

Accessories Standard Accessories 1. Fanuc /Mitsubishi Controller system 2. Full enclosed cover 3. Spindle encoder position system 4.Three Inner encoder feedback system 5. Auto lubrication system 6. Pneumatic system 7. RS232 Interface 8. Operation unit 9.Warming light 10. Working light 11. Tool and tool box Optional Accessories 1. Siemens Controller or Other Controller 2. Spindle oil coolant 3. Umbrella type tool magazine 4. Arm type tool magazine 5. Screw type auto conveyor 6. Chain type auto conveyor 7. 4 axis rotary table 8. Through spindle water coolant 9. Ring spray spindle  Our Service warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

Our Service warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

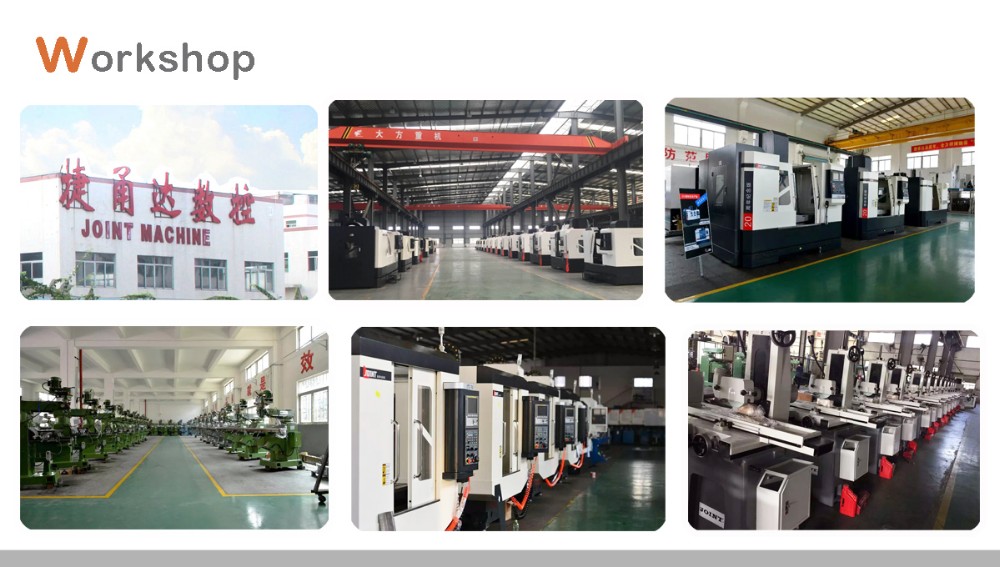

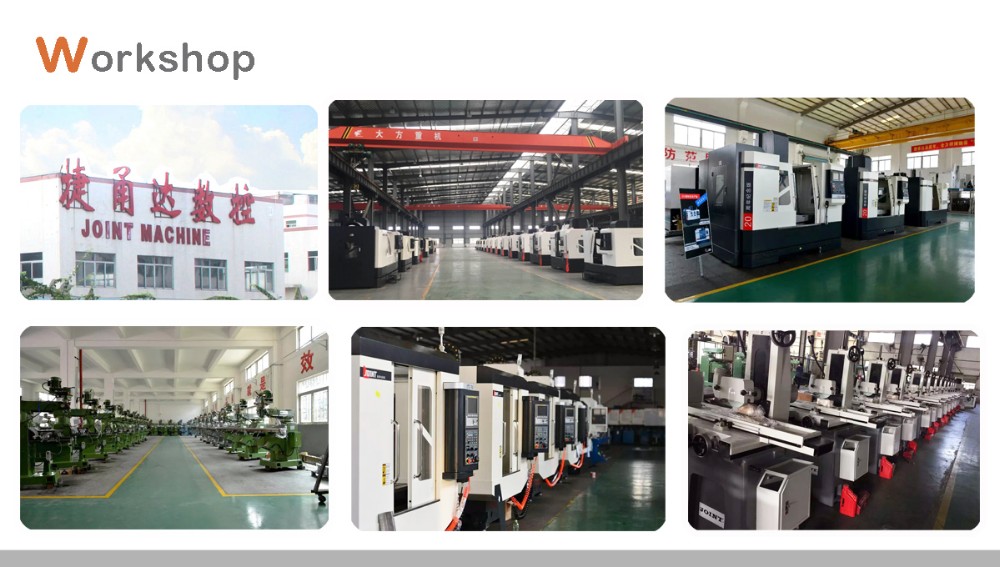

Our Company

Our Company

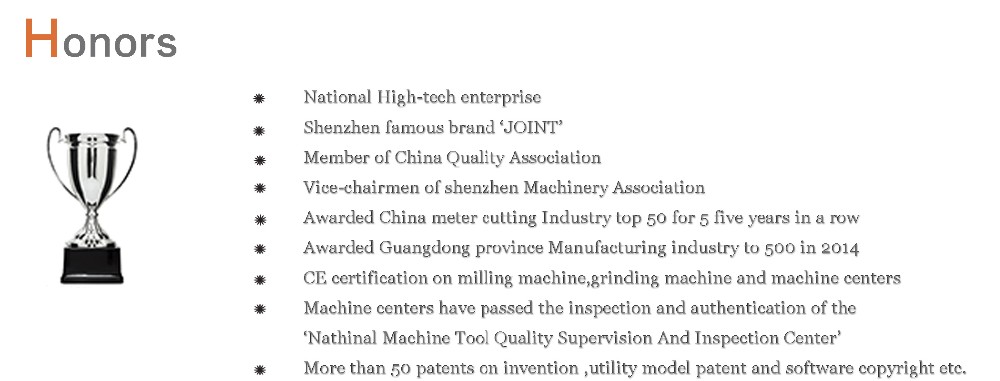

Honor

Honor

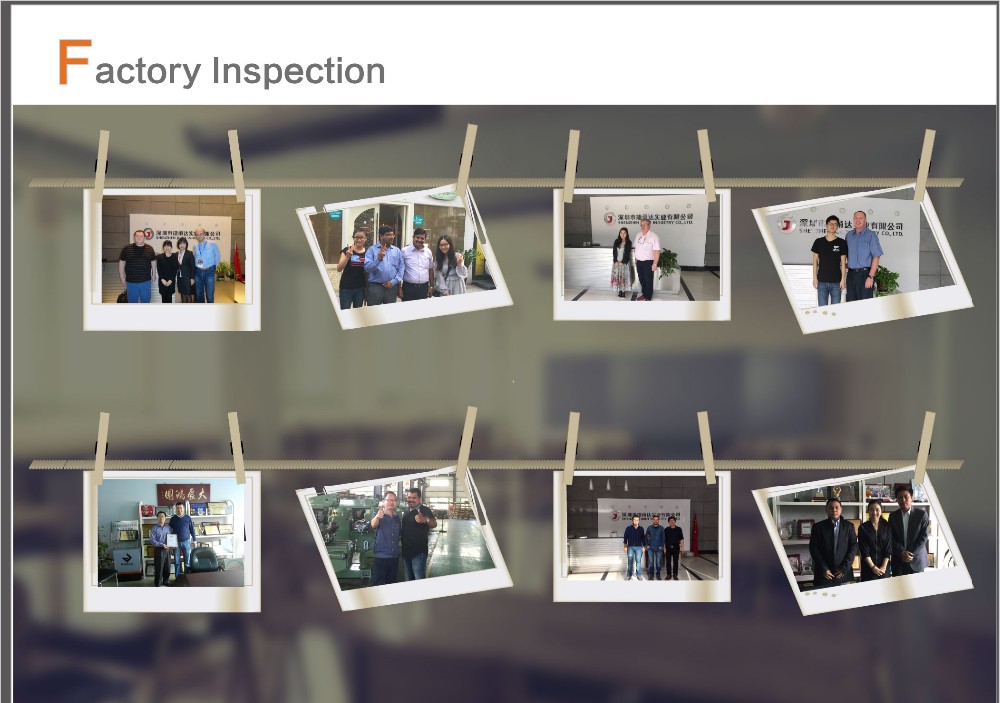

Customers Visit

Customers Visit

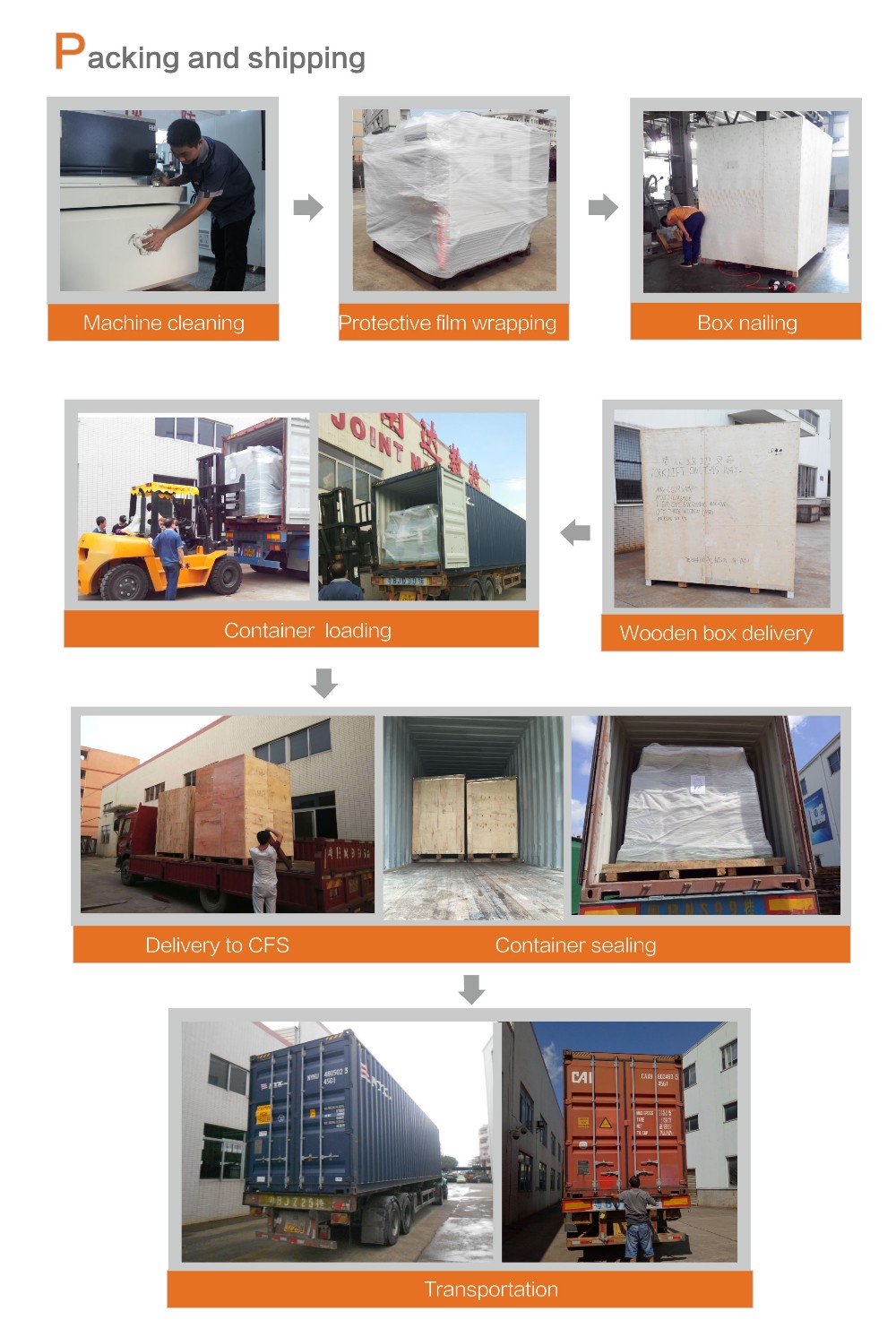

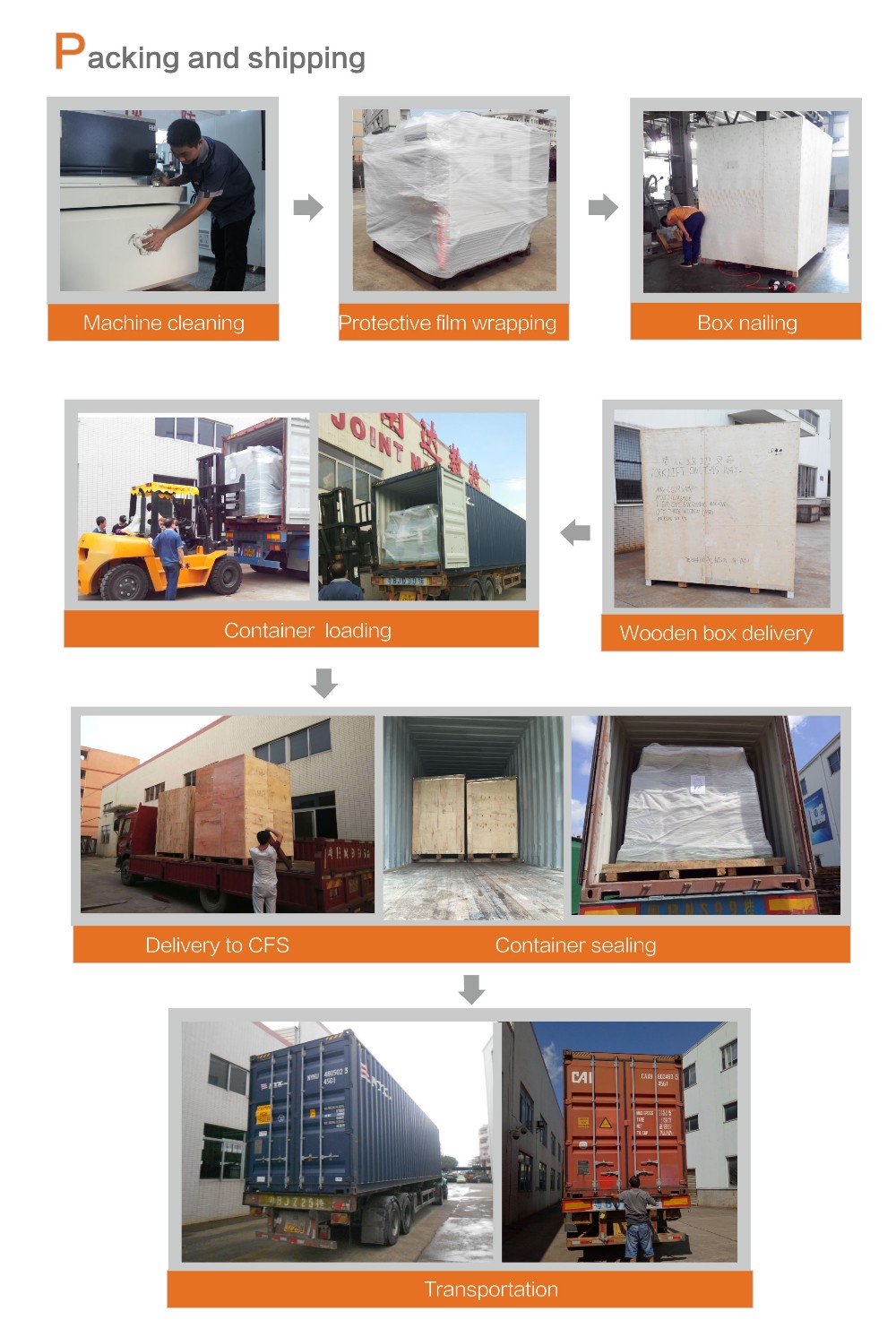

Package & Shipping

Package & Shipping  FAQ

FAQ

(2) Coulping,Spindle bearing,spindle,ball screw,linear slide way,tool magazine,unclamping cylinder and other key parts are all imported from Germany,Japan and Taiwan top brand to ensure high quality and high precision.

(3) Modular cofiguration,can provide customized options to meet different customers processing needs:Spindle water coolant,Gear type spindle-case,10000-15000 rpm/min direct connection spindle.

(4) Suitable for various small to medium parts processing,with faster feed speed,and high rigidity cutting.

Accessories Standard Accessories 1. Fanuc /Mitsubishi Controller system 2. Full enclosed cover 3. Spindle encoder position system 4.Three Inner encoder feedback system 5. Auto lubrication system 6. Pneumatic system 7. RS232 Interface 8. Operation unit 9.Warming light 10. Working light 11. Tool and tool box Optional Accessories 1. Siemens Controller or Other Controller 2. Spindle oil coolant 3. Umbrella type tool magazine 4. Arm type tool magazine 5. Screw type auto conveyor 6. Chain type auto conveyor 7. 4 axis rotary table 8. Through spindle water coolant 9. Ring spray spindle

Accessories Standard Accessories 1. Fanuc /Mitsubishi Controller system 2. Full enclosed cover 3. Spindle encoder position system 4.Three Inner encoder feedback system 5. Auto lubrication system 6. Pneumatic system 7. RS232 Interface 8. Operation unit 9.Warming light 10. Working light 11. Tool and tool box Optional Accessories 1. Siemens Controller or Other Controller 2. Spindle oil coolant 3. Umbrella type tool magazine 4. Arm type tool magazine 5. Screw type auto conveyor 6. Chain type auto conveyor 7. 4 axis rotary table 8. Through spindle water coolant 9. Ring spray spindle  Our Service warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty

Our Service warranty is a year , parts are free of charge to be offered during this period ,oversea service need to charged extra in and out of warranty Our Company

Our Company

Honor

Honor

Customers Visit

Customers Visit

Package & Shipping

Package & Shipping  FAQ

FAQ