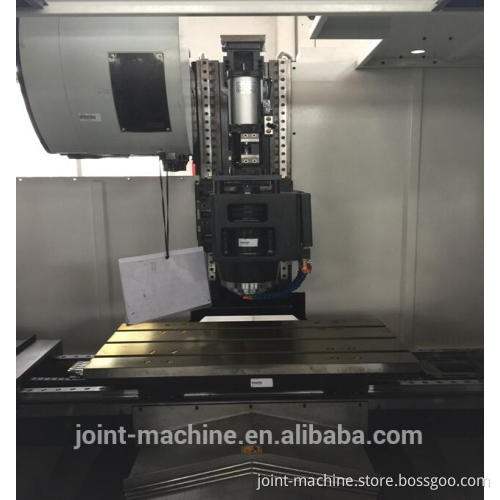

2016 Newest High Speed Parts Processing CNC Machine Center V85 For Promotion

- Delivery Time:

- 1 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong, China (Mainland) |

|---|

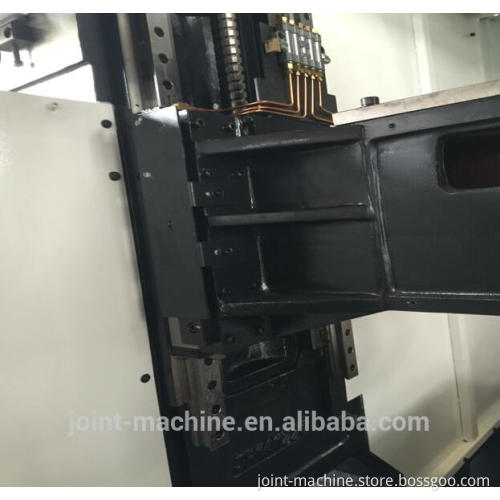

High Speed CNC Machine Center V85 Specifications

High Speed CNC Machine Center V85 Specifications Model | Unit | V85 | ||

| Processing Range | X Axis Travel | mm | 800 | |

Y axis Travel | mm | 500 | ||

Z axis Travel | mm | 500 | ||

Distance between spindle nose to worktable | mm | 170-670 | ||

Table | Table size | mm | 900*450 | |

Load weight | Kg | 500 | ||

T-Slot | Pcs-mm-mm | 3-18-130 | ||

Spindle | Holder size |

| BT40 | |

Diameter of Install | mm | Φ140 | ||

Rivet Size |

| BT40 45° | ||

Spindle Rotary speed | r/min | 10000RPM | ||

Rated output torque | Fanuc N.M | 35 | ||

Spindle motor power | Fanuc kw | 5.5~7.5 | ||

Axis | X/Y Axis motor rated output torque | Fanuc N.M | 13.7 | |

Z Axis motor rated output torque | Fanuc N.M | 22.5 | ||

X/Y axis motor power | Fanuc kw | 2.0 | ||

Z axis motor power | Fanuc kw | 3 | ||

cutting feed speed | mm/min | 15000 | ||

Rapid speed of X/Y/Z axis | m/min | 48/48/48 | ||

|

ATC | Capacity of tool | Tools | 24 |

Diameter /Length /Weight for Tool | mm/mm/kg | 80/200/8 | ||

Max Diameter of Tool | mm | 150 | ||

Choice tool ways |

| Optional | ||

Exchange tool time (tool-tool) | s | 2.5 | ||

Accuracy | X/Y/Z axis Positioning accuracy | mm | 0.006/0.006/0.006 | |

X/Y/Z axis Repeat positioning accuracy | mm | 0.005/0.005/0.005 | ||

Other | Dimension | mm | 2450*2180*2650 | |

Total Power | KVA | 15 | ||

Weight | Kg | 3800 | ||

Our Services

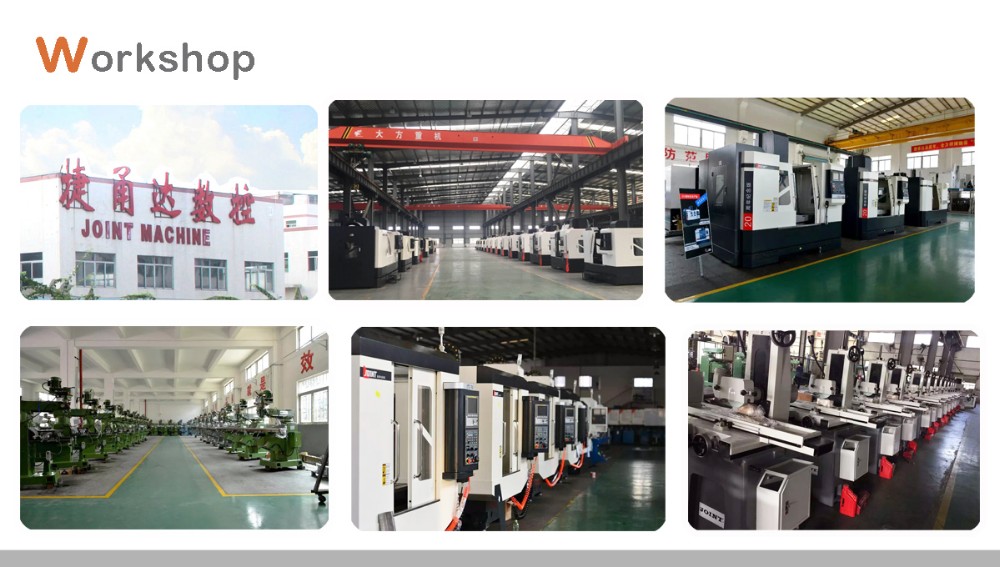

Our Services  Packaging & Shipping Company Information Shenzhen Joint Industry Co., Limited was established in 1995. Our headquarters is located in Pinghu, Longgang District, Shenzhen City, Guangdong Province, China. The company has the modernized plant of 16,000 square meters which has been planned and established autonomously, strong technology research and development capability, and advanced hardware facilities for production and manufacture. It is “National High-tech Enterprise” and has been the top 50 in the industry of manufacture of metal-cutting machine tool in China for many successive years.

Packaging & Shipping Company Information Shenzhen Joint Industry Co., Limited was established in 1995. Our headquarters is located in Pinghu, Longgang District, Shenzhen City, Guangdong Province, China. The company has the modernized plant of 16,000 square meters which has been planned and established autonomously, strong technology research and development capability, and advanced hardware facilities for production and manufacture. It is “National High-tech Enterprise” and has been the top 50 in the industry of manufacture of metal-cutting machine tool in China for many successive years.

Certifications

Certifications

Related Keywords