Latest Wholesales High Quality Vertical CNC Tapping Drilling Machine VTC-500

- Delivery Time:

- 1 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

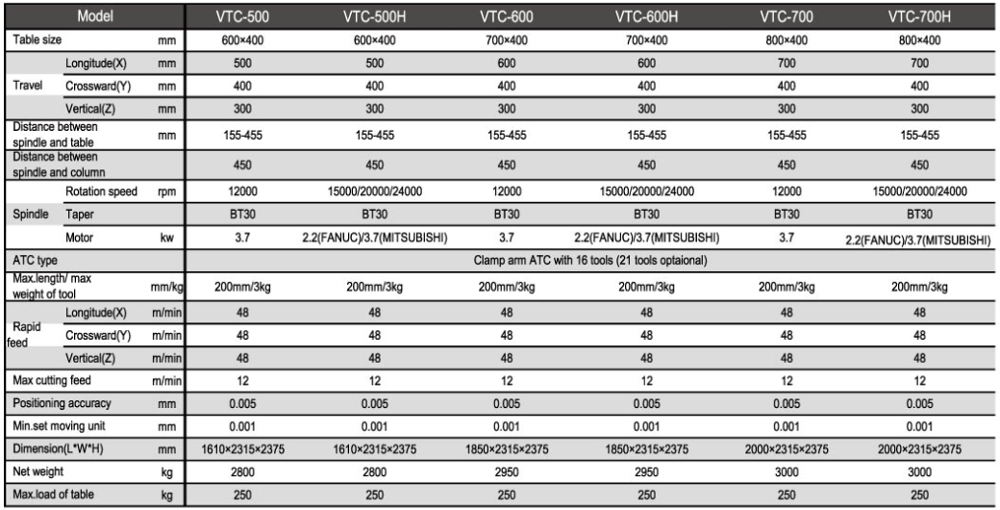

Product Description Latest Wholesales High Quality Vertical CNC Tapping Drilling Machine VTC-500

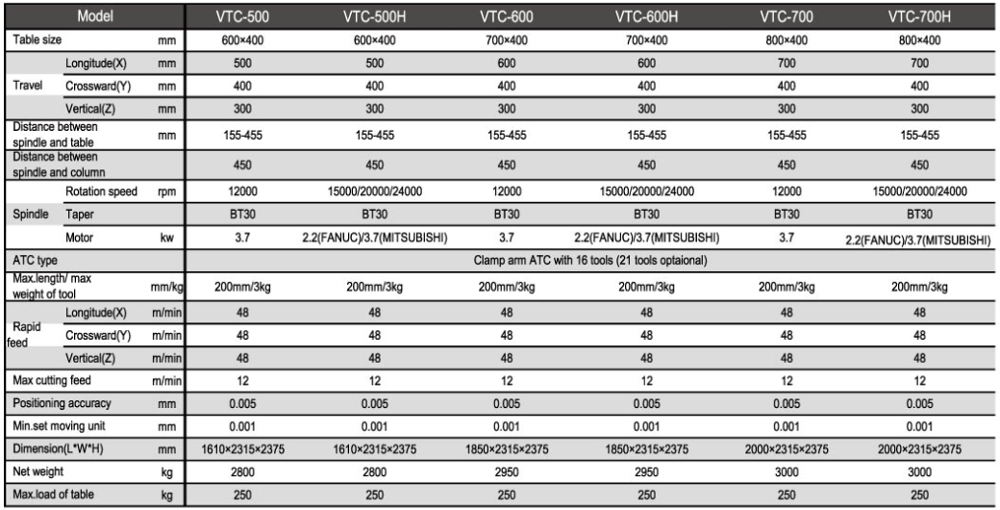

Product Features ♦X,Y,Z axes are linear guide way.3 axes standard rapid feed speed is 48 meters/min(optional up to 60 meters/min). ♦ High-rigidity machine body structure design.In addition to drilling feature,also capable og low-intensity milling and cutting aluminum parts. ♦ Focus on processing small-sized multiple hole precise parts,and have advantages on high speed operation,fast and high precision small hole machinning and fast too changing. ♦ Coupling,spindle bearing,spindle,ball screw,linear slide way,tool magazine,unclamping cylinder and other key parts are all imported from Germany,Japan and Taiwan top brands to ensure high quality and high precision of the products.

Product Features ♦X,Y,Z axes are linear guide way.3 axes standard rapid feed speed is 48 meters/min(optional up to 60 meters/min). ♦ High-rigidity machine body structure design.In addition to drilling feature,also capable og low-intensity milling and cutting aluminum parts. ♦ Focus on processing small-sized multiple hole precise parts,and have advantages on high speed operation,fast and high precision small hole machinning and fast too changing. ♦ Coupling,spindle bearing,spindle,ball screw,linear slide way,tool magazine,unclamping cylinder and other key parts are all imported from Germany,Japan and Taiwan top brands to ensure high quality and high precision of the products. Applications:

Applications:  Accessories Standard Accessories: Optional Accessories:

Accessories Standard Accessories: Optional Accessories:

1)Mitsubishio FanucSystem 1)Oil - water separation system

2)Auto Lubrication System 2)Spindle oil coolant

3)Stainless steel covers of Slide way 3)CNC rotary table

4)Cutting fluid and Filter system 4)Chain type auto chip conveyor

5)Electrical hand wheel

6)Coolant system

7)Alarming light

8)Working light

9)Hammer balance 10)R232 Interface

11)Tool magazine

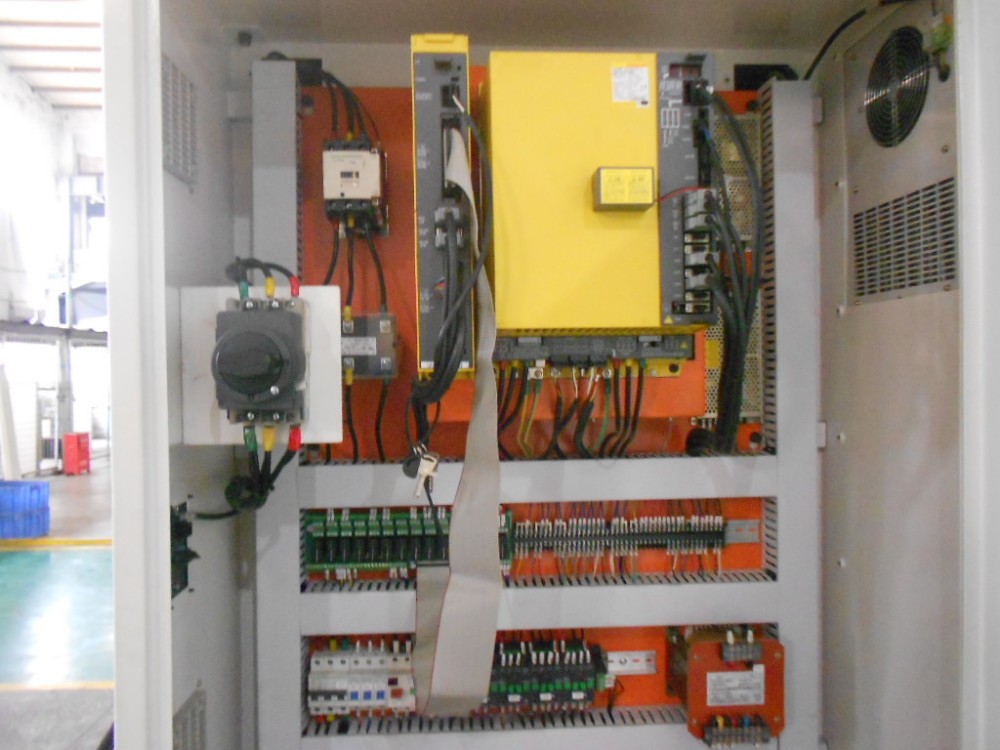

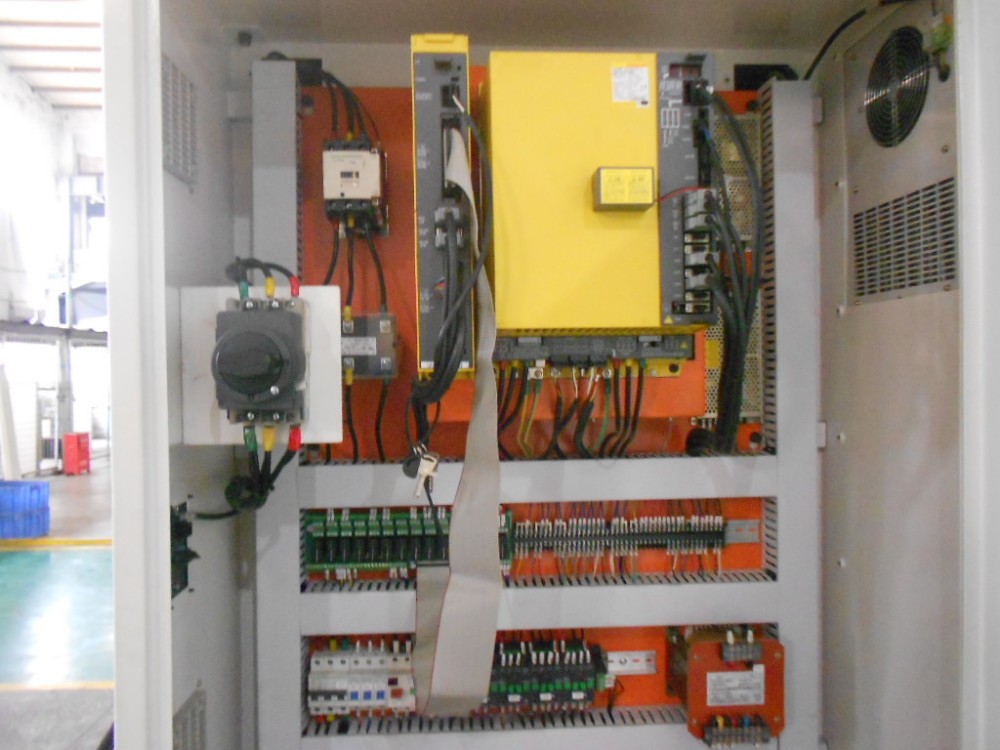

12)Electric box heat exchange

13)Installation pad & adjusting bolt

14)Tools and toolbox

15)Operation manual Our Services Special Advantage: We provide more fanctional and customized products. We provide integrated solutions for auto production line. We accumulate and consistently optimize customer's application data,and provide customer our technical supports on application to ensure better performance. After-sales Service: Warranty is a year. Parts are free of charge to be offered during this period. Oversea service need to charged extra in and out of warranty. Packaging & Shipping Package : Plywood case (one set in one case). Shipping : 3-30 days after payment by vessel.

Our Services Special Advantage: We provide more fanctional and customized products. We provide integrated solutions for auto production line. We accumulate and consistently optimize customer's application data,and provide customer our technical supports on application to ensure better performance. After-sales Service: Warranty is a year. Parts are free of charge to be offered during this period. Oversea service need to charged extra in and out of warranty. Packaging & Shipping Package : Plywood case (one set in one case). Shipping : 3-30 days after payment by vessel. Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

Our development team We have a group of development team that they have professional theory profound skills, technical specialization, rich experience in the industry of the first-class technical research.

Our development team We have a group of development team that they have professional theory profound skills, technical specialization, rich experience in the industry of the first-class technical research.  Our production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Our production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.  Our certificate of honor There are 8 Intellectual property rights,5 the patent In 2008, Our own brand”JOINT” has been the top quality machine’s signal in domestic sales JOINT also has been recognized as”Guangdong Famous Brand” In 2008, Milling machine was recognized as” TOP 10 Famous Brand of Milling Machine “ in China In 2011,our company has been recognized as” national grade HI-Tech Enterprise”. The company set up a ISO9001:2000 quality guarantee system our product through “the country machine quality supervision and inspection center “certification testing

Our certificate of honor There are 8 Intellectual property rights,5 the patent In 2008, Our own brand”JOINT” has been the top quality machine’s signal in domestic sales JOINT also has been recognized as”Guangdong Famous Brand” In 2008, Milling machine was recognized as” TOP 10 Famous Brand of Milling Machine “ in China In 2011,our company has been recognized as” national grade HI-Tech Enterprise”. The company set up a ISO9001:2000 quality guarantee system our product through “the country machine quality supervision and inspection center “certification testing

Product Features ♦X,Y,Z axes are linear guide way.3 axes standard rapid feed speed is 48 meters/min(optional up to 60 meters/min). ♦ High-rigidity machine body structure design.In addition to drilling feature,also capable og low-intensity milling and cutting aluminum parts. ♦ Focus on processing small-sized multiple hole precise parts,and have advantages on high speed operation,fast and high precision small hole machinning and fast too changing. ♦ Coupling,spindle bearing,spindle,ball screw,linear slide way,tool magazine,unclamping cylinder and other key parts are all imported from Germany,Japan and Taiwan top brands to ensure high quality and high precision of the products.

Product Features ♦X,Y,Z axes are linear guide way.3 axes standard rapid feed speed is 48 meters/min(optional up to 60 meters/min). ♦ High-rigidity machine body structure design.In addition to drilling feature,also capable og low-intensity milling and cutting aluminum parts. ♦ Focus on processing small-sized multiple hole precise parts,and have advantages on high speed operation,fast and high precision small hole machinning and fast too changing. ♦ Coupling,spindle bearing,spindle,ball screw,linear slide way,tool magazine,unclamping cylinder and other key parts are all imported from Germany,Japan and Taiwan top brands to ensure high quality and high precision of the products. Applications:

Applications:  Accessories Standard Accessories: Optional Accessories:

Accessories Standard Accessories: Optional Accessories:1)Mitsubishio FanucSystem 1)Oil - water separation system

2)Auto Lubrication System 2)Spindle oil coolant

3)Stainless steel covers of Slide way 3)CNC rotary table

4)Cutting fluid and Filter system 4)Chain type auto chip conveyor

5)Electrical hand wheel

6)Coolant system

7)Alarming light

8)Working light

9)Hammer balance 10)R232 Interface

11)Tool magazine

12)Electric box heat exchange

13)Installation pad & adjusting bolt

14)Tools and toolbox

15)Operation manual

Our Services Special Advantage: We provide more fanctional and customized products. We provide integrated solutions for auto production line. We accumulate and consistently optimize customer's application data,and provide customer our technical supports on application to ensure better performance. After-sales Service: Warranty is a year. Parts are free of charge to be offered during this period. Oversea service need to charged extra in and out of warranty. Packaging & Shipping Package : Plywood case (one set in one case). Shipping : 3-30 days after payment by vessel.

Our Services Special Advantage: We provide more fanctional and customized products. We provide integrated solutions for auto production line. We accumulate and consistently optimize customer's application data,and provide customer our technical supports on application to ensure better performance. After-sales Service: Warranty is a year. Parts are free of charge to be offered during this period. Oversea service need to charged extra in and out of warranty. Packaging & Shipping Package : Plywood case (one set in one case). Shipping : 3-30 days after payment by vessel. Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

Company Information SHENZHEN Joint Industry Co., Ltd specialized in R&D and manufacturing mold processing and machinery parts processing equipments.We developed high quality and high-tech research,development,manufacturing,service team and management system,and expanded products to more than 10 series from milling machines, to machine centers. With the exceptional quality products and distinctire brand reputation,our products are sold to more than 40 developed cities all over China,and also to more than 20 countries all over the world across Asia,Europe and America.

Our development team We have a group of development team that they have professional theory profound skills, technical specialization, rich experience in the industry of the first-class technical research.

Our development team We have a group of development team that they have professional theory profound skills, technical specialization, rich experience in the industry of the first-class technical research.  Our production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.

Our production workshop Our company independent planning and construction of modern vertical machine center production line ,CNC milling machine production line ,Dragon frame CNC machine production line , electric discharge machine production line, milling machine production line, grinder machine production line, precise head assembly workshop etc.  Our certificate of honor There are 8 Intellectual property rights,5 the patent In 2008, Our own brand”JOINT” has been the top quality machine’s signal in domestic sales JOINT also has been recognized as”Guangdong Famous Brand” In 2008, Milling machine was recognized as” TOP 10 Famous Brand of Milling Machine “ in China In 2011,our company has been recognized as” national grade HI-Tech Enterprise”. The company set up a ISO9001:2000 quality guarantee system our product through “the country machine quality supervision and inspection center “certification testing

Our certificate of honor There are 8 Intellectual property rights,5 the patent In 2008, Our own brand”JOINT” has been the top quality machine’s signal in domestic sales JOINT also has been recognized as”Guangdong Famous Brand” In 2008, Milling machine was recognized as” TOP 10 Famous Brand of Milling Machine “ in China In 2011,our company has been recognized as” national grade HI-Tech Enterprise”. The company set up a ISO9001:2000 quality guarantee system our product through “the country machine quality supervision and inspection center “certification testing