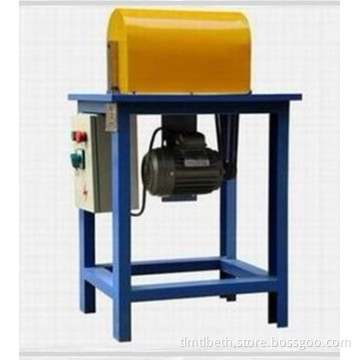

MgO powder filling machine for heating element

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen,Guangdong |

|---|---|

| Supply Ability: | 10sets/month |

| Certificate: | CE/ISO9001:2000 |

Product Description

Product Description

Detailed Product Description

Use to fill MgO powder inside of heating elements

Can compare with CSM and Kanthal machine

Good quality and low price

Functions:

- PLC automatically controlled, human-computer interface and control the oscillation frequency by electron speed regulator.

- It adopts jet nozzle which assure almost zero MgO loss.

- Vibrator guarantee the powder density and the density could be above 2.20g/cm3.

- The filling tube moving speed controlled by frequency control.

- Big and small powder box design. Electronic adjusting the exerted length of terminal pin.

- Indicate how to clear fault automatically.

- 12,18,24,36 and 48 position machines are available to satisfy customers` production requirements.

- Tube diameter :below 16mm, tube length:beow 6000mm.It can be custom-made

Main technical parameters:

1. Power supply: 220V, 50Hz

2. Rated power: 2.0KW

3. Air supply: 5-7kg/cm2

4. Efficiency: 6500pcs/8h(tube length 250mm)

5. Feeding speed: 250-300/Min.

6. Size(L*W*H):1800*850*3300(mm) (1meter tube)

7. Weight: 600kg

Related Keywords

Related Keywords