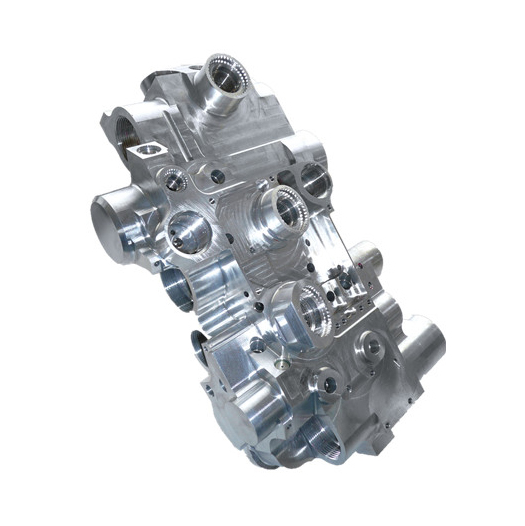

Machinery company custom procurement of precision parts

-

$1.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | Sufficient and customizable |

| Supply Ability: | Timely |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | EXW,FOB |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

Precision cnc parts processing

The programming methods of NC machining are divided into manual (manual) programming and automatic programming. Manual programming, the entire content of the program is manually written according to the instruction format specified by the CNC system. Automatic programming is computer programming, which can be divided into automatic programming methods based on language and painting. However, no matter what kind of automatic programming method is adopted, corresponding hardware and software are required.

The processing of precision mechanical parts requires the production of high-quality and stable products. In order to achieve this goal, the staff must have rich experience in machining and excellent technology. As we all know, machining is a delicate job, and it is necessary to have excellent technical skills. well done.

It can be seen that the realization of CNC machining programming is the key. But programming alone is not enough. CNC machining also includes a series of preparations that must be done before programming and the aftermath of programming. Generally speaking, the CNC machining process mainly includes the following contents:

(1) Select and determine the parts and contents for CNC machining;

(2) Process analysis of CNC machining of parts drawings;

(3) Process design of CNC machining;

(4) Mathematical processing of part drawings;

(5) Write the processing program list;

(6) Make control medium according to the program list;

(7) program verification and modification;

(8) First piece trial processing and on-site problem handling;

(9) The finalization and filing of CNC machining process documents.

1. Reasonable selection of machine tools

When machining parts on CNC machine tools, there are generally two situations.

The first case: there are part drawings and blanks, and a CNC machine tool suitable for processing the part should be selected.

The second case: there is already a CNC machine tool, and parts suitable for processing on the machine must be selected. In either case, the main factors to be considered are the material and class of the blank, the complexity of the contour shape of the part, the size, the machining accuracy, the number of parts, and the heat treatment requirements.

To sum up, there are three points:

①It is necessary to ensure the technical requirements of the processed parts and process qualified products.

②Conducive to improving productivity.

③ Reduce production costs (processing costs) as much as possible.

Process analysis

The NC machining process of the parts to be processed involves a wide range of issues. The following combined with the possibility and convenience of programming propose some main contents that must be analyzed and reviewed.

1. Dimensions should conform to the characteristics of CNC machining

In NC programming, the dimensions and positions of all points, lines and surfaces are based on the programming origin. Therefore, it is best to give the coordinate dimensions directly on the part drawing, or try to quote the dimensions with the same datum.

2. The conditions of geometric elements should be complete and accurate

In programming, programmers must fully grasp the geometric element parameters that constitute the part outline and the relationship between the geometric elements. Because all geometric elements of the part contour need to be defined during automatic programming, and the coordinates of each node need to be calculated during manual programming, no matter which point is unclear or uncertain, programming cannot be performed. However, due to the lack of consideration or neglect by the part designers in the design process, the parameters are often incomplete or unclear, such as whether the arc and the straight line, the arc and the arc are tangent, intersecting or separating. Therefore, when reviewing and analyzing the drawings, you must be careful and contact the designer in time if you find any problems.

Processing principle

(1) The processing of the previous process cannot affect the positioning and clamping of the next process [2].

(2) First inside and then outside, that is, the inner cavity (inner hole) is processed first, and then the outer shape is processed.

(3) The process of processing with the same installation or using the same tool should preferably be carried out continuously to reduce errors caused by repositioning or tool change.

⑷In the same installation, the process that has less influence on the rigidity of the workpiece should be carried out first.

CNC machine tool is a kind of advanced processing equipment with high degree of automation and complex structure. In order to give full play to the advantages of machine tools, improve production efficiency, manage, use and repair CNC machine tools well, the quality of technicians and civilized production are particularly important. . In addition to being familiar with and mastering the performance of CNC machine tools and being skilled in operation, operators must also develop good working habits and rigorous work styles for civilized production, and have good professional quality, sense of responsibility and spirit of cooperation. The following should be done during operation:

(1) Strictly abide by the safety operation rules of CNC machine tools. Do not operate the machine without professional training.

(2) Strictly abide by the commute and shift system.

(3) To use and manage the machine well, and have a strong sense of responsibility.

(4) Keep the environment around the CNC machine tools clean and tidy.

(5) Operators should wear work clothes and work shoes, and are not allowed to wear dangerous clothing.

Operating procedures

In order to use CNC machine tools correctly and reasonably, reduce the incidence of its failures, and operate methods. The machine tool can only be operated with the consent of the machine tool management personnel.

CNC machining center

Company Situation

Shenzhen Xingkeda Technology Trade Co., Ltd. is located in Pinghu, Longgang, Shenzhen, Guangdong. It is a professional high-precision non-standard mechanical parts processing and customized factory. It has a professional production workshop, including 30 CNC computer gongs and 20 CNC lathes. Taiwan, 10 milling machines, 10 grinders, 5 5-axis CNC machines, 2 general vehicles, and equipped with high-end three-coordinate, two-dimensional inspection equipment and professionals, capable of producing various aviation components, precision auto parts, Precision medical equipment parts, semiconductors, automation equipment accessories, hardware high-speed stamping products, small sheet metal machines, boxes With rich professional experience and scientific and technological strength, we continue to innovate, from product order to parts production, to completion of delivery. , To provide users with products with excellent performance. And with its excellent reputation and high-quality service, it is well received by new and old customers. Let us give your products to us, peace of mind, rest assured, peace of mind! We mainly serve the fields of intelligent automation, precision parts of semiconductor equipment, intelligent robots, aerospace, automobile industry, wind power generation, health and medical equipment, optical products, microwave communication and other fields.

Workshop situation

Applicable fields: semiconductor, aviation, energy, automotive, communications, medical and other industries.

|

|

|

|

|

|

|

|

|

|

|

|

Related Keywords