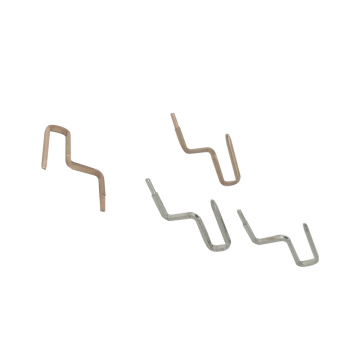

Electronic components stamping parts

-

$1.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | Sufficient and customizable |

| Supply Ability: | Timely |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | EXW,FOB |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

Bending and stamping processing

Stamping parts processing flow:

1. Determine the amount of deformation compensation according to the material, product structure, etc.

2. Design the die to punch out the finished or semi-finished product according to the compensation amount.

3. Process semi-finished products to finished products.

4. Undesirable phenomena include cracks, wrinkling, strain, uneven thickness, non-forming, etc.

Product function: The molded parts are covered with glue to protect them.

Product material: The material is galvanized sheet.

Product features: Forming complex parts cannot have burrs.

Product technology: blanking, punching, composite molding.

Stamping parts are mainly formed by stamping metal or non-metal sheet materials with the help of the pressure of the press through the stamping die. It mainly has the following characteristics:

① Stamping parts are made by stamping under the premise of low material consumption. The parts are light in weight and good in rigidity. After the sheet is plastically deformed, the internal structure of the metal is improved, which improves the strength of the stamping parts. .

② Stamping parts have high dimensional accuracy, and are uniform in size with the mold parts, and have good interchangeability. No further machining is required to meet general assembly and use requirements.

③ During the stamping process, since the surface of the material is not damaged, it has a good surface quality and a smooth and beautiful appearance, which provides convenient conditions for surface painting, electroplating, phosphating and other surface treatments.

Stamping is a production technology of product parts with a certain shape, size and performance by means of the power of conventional or special stamping equipment, so that the sheet metal is directly subjected to deformation force and deformed in the mold. Sheet material, mold and equipment are the three elements of stamping processing. Stamping is a metal cold deformation processing method. Therefore, it is called cold stamping or sheet stamping, or stamping for short. It is one of the main methods of metal plastic working (or pressure working), and also belongs to material forming engineering technology.

50 to 60% of the steel in the world is made of sheets, most of which are finished products that have been pressed. Car body, radiator fins, steam drums of boilers, shells of containers, iron core silicon steel sheets of motors and electrical appliances, etc. are all stamped and processed. There are also a large number of stamping parts in products such as instrumentation, household appliances, office machines, and storage devices. Stamping is an efficient production method, using composite molds, especially multi-station progressive molds, which can complete multi-stage stamping technology operations on one press to complete the automatic generation of materials. The production speed is fast, the rest time is long, the production cost is low, and the collective can produce hundreds of pieces per minute, which is favored by many processing plants.

Stamping parts are more powerful than castings and forgings, and have the characteristics of thinness, lightness and strength. Stamping can produce workpieces with reinforcing ribs, ribs, coils or flanges that are difficult to manufacture in this skilled diameter to improve their rigidity. Due to the rejection of rough molds, the precision of the workpiece can reach micron level, with high precision and consistent specifications, and can punch out holes, bosses, etc. In actual production, technical tests similar to the stamping process are often used, such as deep drawing performance tests, bulging performance tests, etc. to test the stamping performance of materials to obtain finished product quality and high pass rate.

separation process

It is a process in which the stamping part and the sheet material are separated from each other along a certain contour line during the stamping process. As shown in the table below:

| Process name | Process features | Scope of application |

| blanking | Use the die to punch the sheet along the closed line, and the punched part is the workpiece. | For the manufacture of flat parts of various shapes |

| punching | The sheet is punched along the closed line with a die, and the punched part is scrap. | For punching holes in flat or formed parts |

| cut off | Cut the sheet with scissors or die, the cutting line is not closed. | Mostly used for processing flat parts with simple shapes |

| trimming | Use a die to punch out excess material from the edge of the workpiece. | Mainly used for three-dimensional forming parts |

| grooving | Punching narrow, long grooves in sheet stock or formed parts |

|

| section | The semi-finished product made by stamping is cut into two or more parts. | Mostly used after asymmetrical double or group punching |

forming process

It is the plastic deformation of the blank under the condition that it is not damaged to form a part with the required shape and dimensional accuracy. As shown in the table below:

| Process name | Process features |

| bending | Use a die to bend a sheet into an angled part, or rebend an already bent part |

| stretch | Press the sheet into hollow parts of any shape with a die, or further deform the hollow parts |

| flanging | Use a mold to turn the hole or outer edge of the sheet into a straight wall |

| rise | The die is used to apply an outward radial force to the hollow part to expand the local diameter. |

| Neck | Use a die to apply radial pressure from outside to inside on the mouth of the hollow part to reduce the local diameter. |

| extrusion | The blank is placed in the die cavity and pressed to extrude it from the die cavity to form hollow or solid parts. |

| round | The end of the sheet is rolled into a nearly closed round head for processing hinge-like parts. |

| Flaring | A deformation method in which the radial dimension of a hollow or tubular blank is enlarged at a certain position. |

| school shape |

Flatten uneven surfaces of workpieces; press bent or deep drawn workpieces into correct shape |

main application

Because stamping has such advantages, stamping processing is widely used in various fields of the national economy. For example, there are stamping processes in aerospace, aviation, military industry, machinery, agricultural machinery, electronics, information, railways, post and telecommunications, transportation, chemicals, medical equipment, household appliances and light industry. Not only is it used by the entire industry, but everyone is directly connected to stamping products. There are many large, medium and small stamping parts on planes, trains, automobiles and tractors. The body, frame and rim of the car are all stamped and processed. According to relevant survey statistics, 80% of bicycles, sewing machines, and watches are stamped parts; 90% of TV sets, tape recorders, and cameras are stamped parts; there are also food metal cans, steel boilers, enamel bowls and stainless steel tableware. All of them are stamped products using molds; even the hardware of computers cannot lack stamping parts.

Lathes and Presses

Company Situation

Shenzhen Xingkeda Technology Trade Co., Ltd. is located in Pinghu, Longgang, Shenzhen, Guangdong. It is a professional high-precision non-standard mechanical parts processing and customized factory. It has a professional production workshop, including 30 CNC computer gongs and 20 CNC lathes. Taiwan, 10 milling machines, 10 grinders, 5 5-axis CNC machines, 2 general vehicles, and equipped with high-end three-coordinate, two-dimensional inspection equipment and professionals, capable of producing various aviation components, precision auto parts, Precision medical equipment parts, semiconductors, automation equipment accessories, hardware high-speed stamping products, small sheet metal machines, boxes With rich professional experience and scientific and technological strength, we continue to innovate, from product order to parts production, to completion of delivery. , To provide users with products with excellent performance. And with its excellent reputation and high-quality service, it is well received by new and old customers. Let us give your products to us, peace of mind, rest assured, peace of mind! We mainly serve the fields of intelligent automation, precision parts of semiconductor equipment, intelligent robots, aerospace, automobile industry, wind power generation, health and medical equipment, optical products, microwave communication and other fields.

Workshop situation

Applicable fields: semiconductor, aviation, energy, automotive, communications, medical and other industries.

|

|

|

|

|

|

|

|

|

|

|

|

Related Keywords