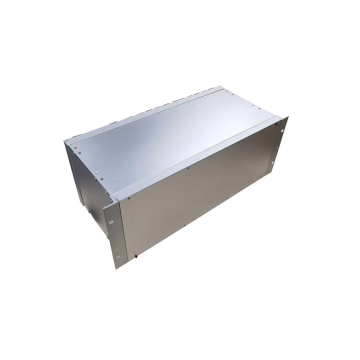

Aluminum alloy housing chassis processing

-

$1.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | Sufficient and customizable |

| Supply Ability: | Timely |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Money Gram,Western Union |

| Incoterm: | EXW,FOB |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

Aluminum alloy housing chassis processing

Category: Aluminum alloy chassis

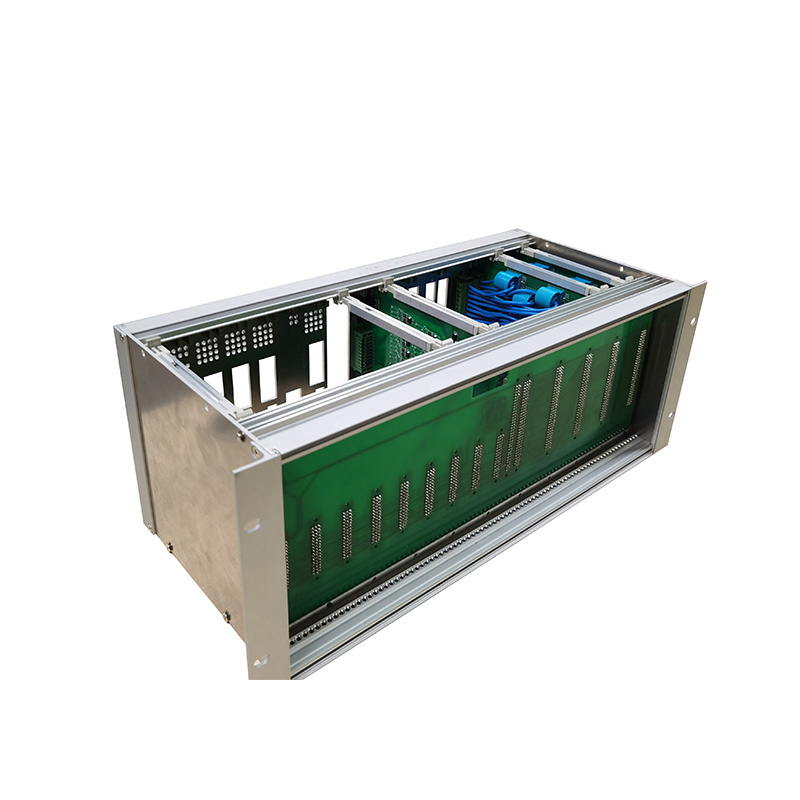

Introduction: The material of aluminum alloy chassis is a kind of chassis made of aluminum alloy. Aluminum alloy is made of pure aluminum by adding some alloy elements. It has the characteristics of light weight, strong structure, high structural strength and good heat dissipation performance. Therefore, the aluminum case is a case that is very suitable for the material requirements of the case. At present, in the industries of instruments, meters, electronics, communications, automation, sensors, smart cards, industrial control, precision machinery and other industries, aluminum alloy materials are used in the material selection of the box.

Stamping processing is to use the power of conventional or special stamping equipment, so that the sheet is directly subjected to deformation force in the mold and deformed, so as to obtain a certain shape, size and stamping processing. The production technology of product parts that are directly subjected to deformation force in the mold and deformed to obtain a certain shape, size and performance. Sheet material, mold and equipment are the three elements of stamping processing. Stamping is a metal cold deformation processing method. Therefore, it is called cold stamping or sheet stamping, or stamping for short. It is one of the main methods of metal plastic working (or pressure working), and also belongs to the production technology of product parts with material forming engineering and technical performance. Sheet material, mold and equipment are the three elements of stamping processing. Stamping is a metal cold deformation processing method. Therefore, it is called cold stamping or sheet stamping, or stamping for short. It is one of the main methods of metal plastic working (or press working), and also belongs to material forming engineering technology.

Product Description

Outdoor chassis cabinets, as the name suggests, are used for outdoor equipment storage equipment. For the precautions of outdoor equipment systems, most people just think that buying a high-quality outdoor chassis cabinet product is enough, because a good outdoor chassis cabinet can ensure that the internal machine is not damp. , no water, lightning protection and so on. In fact, if you want the equipment to be moisture-proof, waterproof, lightning-proof, etc., in addition to a good-quality equipment box, you must also pay attention to the internal installation:

First, the placement of the optical transceiver

1. Pay attention to moisture-proof, condensation-proof and waterproof. The best way is to wall-hang it in the outdoor cabinet, or put it on the clapboard;

2. Pay attention to grounding lightning protection. For optical transceivers without secondary lightning protection, it is best to ground them. If there is a grounding port, connect to this port. .

2. Coiled cable: There are no specific requirements for the cable, beautiful wiring, pay attention to the firmness of the BNC head, and the optical fiber is worth mentioning. In addition, the jumper should not be stepped on, the redundant part should be tied in a loop, and the optical fiber ceramic head should not be dirty. Clean it with alcohol.

1. Corrosion resistance

The density of aluminum shell processing is only 2.7g/cm3, which is about 1/3 of the density of steel, copper or brass (7.83g/cm3, 8.93g/cm3, respectively). Aluminum exhibits excellent corrosion resistance under most environmental conditions, including in air, water (or brine), petrochemicals, and many chemical systems.

2. Conductivity

Aluminum housing machining is often chosen due to its excellent electrical conductivity. On an equal weight basis, aluminum has nearly twice the electrical conductivity of copper.

3. Thermal conductivity

The thermal conductivity of aluminum alloys is about 50-60% of that of copper, which is beneficial for the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and automobile cylinder heads and radiators.

4. Non-ferromagnetic

Aluminium profiles are non-ferromagnetic, an important property for the electrical and electronic industries. Aluminium profiles are not self-igniting, which is important for applications involving handling or contact with flammable and explosive materials.

5. Machinability

The machinability of the aluminum case processing is excellent. Among various wrought and cast aluminum alloys, and in the various states in which these alloys are produced, the machining properties vary considerably, requiring special machine tools or techniques.

6. Formability

The specific tensile strength, yield strength, ductility and corresponding work hardening rate govern the variation in allowable deformation.

product description】

1.Material: steel, copper, aluminum alloy, engineering plastic

2. Price: Factory price

3. Surface Treatment (Surface Treatment): Nitriding Electroplating

4. Manufacturing service: OEM or ODM are available.

5. Tolerance: can keep +/-0.005mm, high precision

6. Specifications: Products can be manufactured according to customer's drawings.

7. Drawing software: CAD/Solidworks/Mastercam/UGNX.10

8. Manufacturing process and procedures: CNC lathes, milling machines, workbenches, etc.

9. Packing: plastic bag and PE foam inside, carton outside. We can pack as per customer's request

Lathes and Presses

Company Situation

Shenzhen Xingkeda Technology Trade Co., Ltd. is located in Pinghu, Longgang, Shenzhen, Guangdong. It is a professional high-precision non-standard mechanical parts processing and customized factory. It has a professional production workshop, including 30 CNC computer gongs and 20 CNC lathes. Taiwan, 10 milling machines, 10 grinders, 5 5-axis CNC machines, 2 general vehicles, and equipped with high-end three-coordinate, two-dimensional inspection equipment and professionals, capable of producing various aviation components, precision auto parts, Precision medical equipment parts, semiconductors, automation equipment accessories, hardware high-speed stamping products, small sheet metal machines, boxes With rich professional experience and scientific and technological strength, we continue to innovate, from product order to parts production, to completion of delivery. , To provide users with products with excellent performance. And with its excellent reputation and high-quality service, it is well received by new and old customers. Let us give your products to us, peace of mind, rest assured, peace of mind! We mainly serve the fields of intelligent automation, precision parts of semiconductor equipment, intelligent robots, aerospace, automobile industry, wind power generation, health and medical equipment, optical products, microwave communication and other fields.

Workshop situation

Applicable fields: semiconductor, aviation, energy, automotive, communications, medical and other industries.

|

|

|

|

|

|

|

|

|

|

|

|

Related Keywords