Automated production line customization

-

$50000.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Others

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | Customizable |

| Supply Ability: | Timely |

| Payment Type: | Others |

| Incoterm: | FOB |

| Transportation: | Others |

Automated production line customization

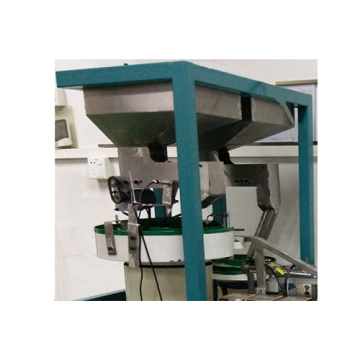

Equipment introduction

1. This equipment solves the traditional manual assembly, effectively reduces labor costs, realizes automatic assembly, automatic testing and other functions, and realizes truly unmanned automatic production.

2. This device is two general-purpose devices.

3. This equipment is fully automatic, with automatic feeding of vibrating plate, automatic feeding of manipulator, automatic assembly, automatic oiling, automatic detection, and automatic unloading. The manpower only needs to pour the processed products into the vibrating plate, which is convenient and fast.

4. Equipped with programmable logic controller (PLC), all mechanical actions are designed by software and tested by computer to ensure that each action is reasonable and without conflict. The equipment control interface is a full touch man-machine interface, which can be operated according to the interface prompts. It is simple and clear, and the novice can also operate it proficiently. The equipment has automatic counting and automatic alarm functions, which is convenient for the operator to calculate the output and troubleshoot.

Application field

The automatic production line for auto handbrake parts is used in the automotive industry: oil pump assembly, handbrake parts assembly, valve body assembly, or other hardware parts assembly!

technical parameter

|

product name |

Auto Handbrake Parts Automatic Production Line |

|

model |

YL-QC161022 |

|

power |

13KW |

|

Voltage |

380V/50Hz |

|

air pressure |

0.4-0.7MPA |

|

Equipment capacity |

30-35PCS/MIN |

|

Features |

Two common |

|

Total weight of the unit |

4000kg |

|

Dimensions |

8000×2000×1800 |

For the automotive, electronics, aerospace, medical industries, customized services for various workstations, production line unit functional areas. It can save a lot of front-line operators and solve the problems of difficult recruitment and high labor costs for enterprises.

Improve production line efficiency and increase input-output ratio.

Efficient docking with MES system, online recording, tracking product quality records.

Company Profile

Shenzhen Yonglun Intelligent Equipment Technology Co., Ltd. was established in early 2016. The company has been focusing on the R&D and manufacturing of automated production equipment. Our company currently has complete sets of automated assembly and testing equipment, as well as mature R&D design, manufacturing, installation and commissioning and technical services. Relying on the advantages of independent core technology and system integration, the company provides customers with complete product production planning plans and production workshop layout plans, improves production efficiency and product quality, reduces production costs, creates higher profits for the company, and produces for the company. Or undertake product foundry has played a key role.

Shenzhen Yonglun Automation Equipment Co., Ltd. has more than 20 independent patent inventions. Automatic secondary processing equipment and automatic assembly machine can be provided : automatic assembly machine, vape cotton wrapping machine, vape cotton rolling machine, pod assembly machine, vape oil filling machine, tape packaging machine, spigot machine, screw machine, copper Pipe drilling machine, hardware assembly equipment, plastic assembly and other automation equipment

The company insists on technological innovation and respect for talents, so as to build an advanced technology research and development team; we focus on every detail, control the quality of each component, complete the assembly and debugging of equipment with precise thinking, and can do according to the individual needs of customers. an effective correspondence.

The company adheres to scientific and technological innovation, takes high quality as the bottom line, and pursues customer satisfaction;

Related Keywords