Uniform insulation thickness PV cable

- Min. Order:

- 5000 Meter

- Min. Order:

- 5000 Meter

- Transportation:

- Ocean, Land

- Port:

- Shenzhen, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land |

| Port: | Shenzhen,Hongkong |

Product Description

Product Description

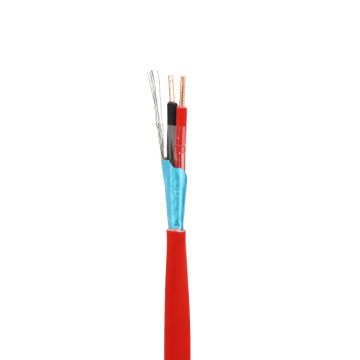

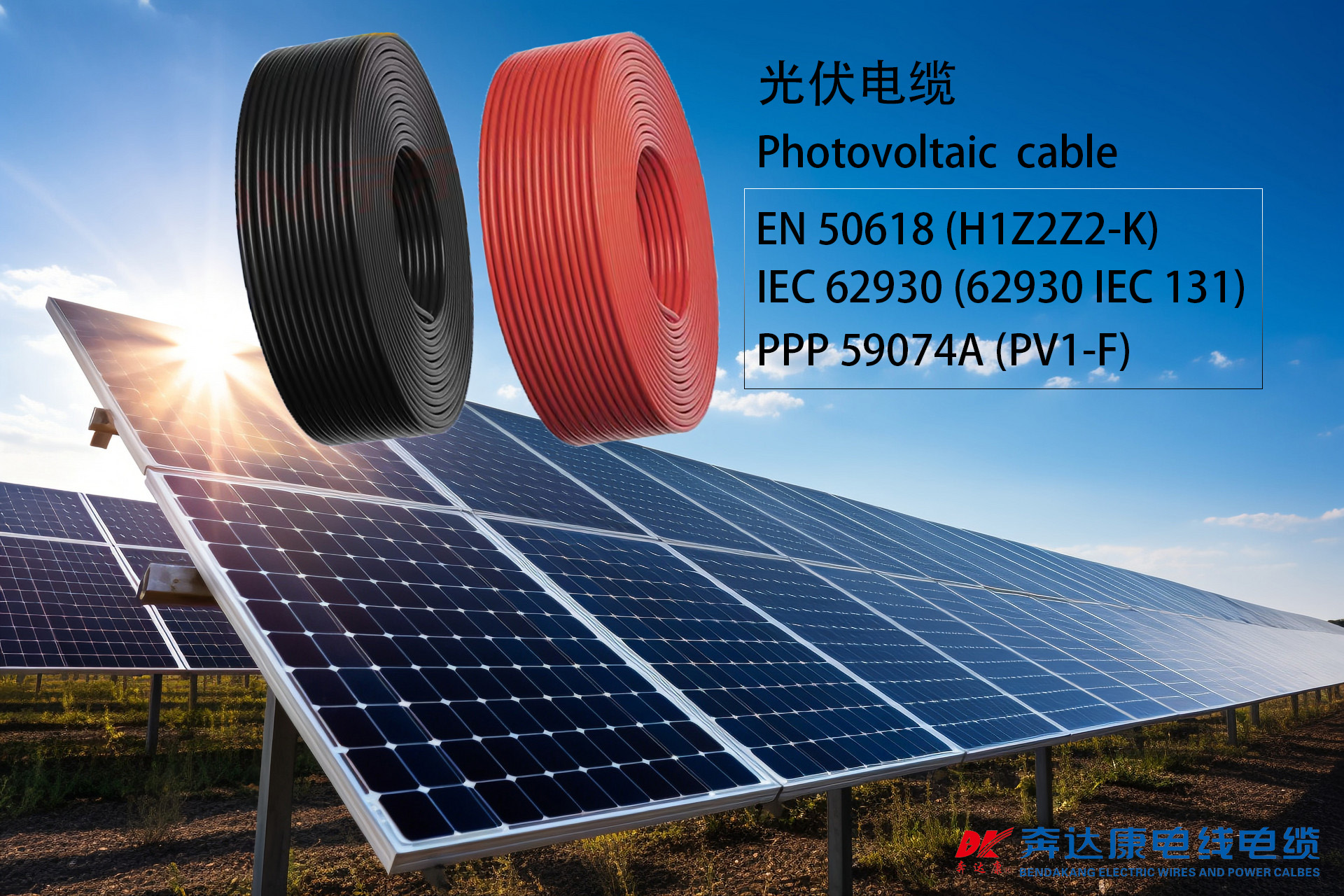

Uniform insulation thickness Photovoltaic cable is a high-performance cable designed for solar power generation systems. Its core feature is the uniformity of insulation thickness.

1. Technical parameters of Solar Cable

Insulation thickness deviation: ≤±0.05mm (industry standards usually allow ±0.1mm), ensuring uniform electric field distribution and reducing the risk of local breakdown.

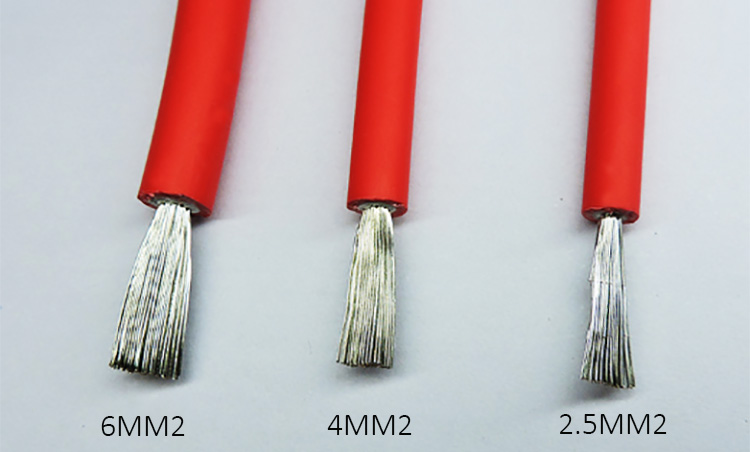

Conductor resistance: ≤5.09Ω/km (4.0mm² model) at 20℃, in line with IEC 60228 Class 5 flexible conductor standard.

Temperature range: -40℃ to +120℃ (short-term temperature resistance 150℃), adaptable to extreme climates.

Insulation material: cross-linked polyolefin (XLPO) or low-smoke halogen-free (LSZH) material is used, and it passes the UL VW-1 vertical burning test.

2. Quality advantages of pv wire

Uniform insulation design

Reduce the risk of partial discharge, and the measured partial discharge is ≤5pC (IEC 60885-3 standard).

Improve the life of the cable, and the uniform insulation layer reduces the thermal aging rate by 30%.

Environmental protection and safety

LSZH model smoke density (Dm) ≤ 200, pH value ≥ 4.3, in compliance with the EU RoHS directive.

No heavy metals such as lead/cadmium, passed the REACH regulation SVHC test.

Easy to install

The insulation layer thickness is uniform, and the stripping efficiency is increased by 40% (actual measured data).

Light weight (4.0mm² model weight is about 85kg/km), reducing transportation and installation costs.

3. Key data and performance advantages

Electrical performance

Insulation resistance: ≥1000MΩ·km (DC 500V test), far exceeding the 500MΩ·km standard of ordinary cables.

Withstand voltage test: 3.5kV/5min without breakdown, ensuring long-term stability of the system.

Attenuation rate: signal transmission attenuation ≤0.2dB/m (at 1MHz frequency), suitable for long-distance wiring.

Mechanical properties

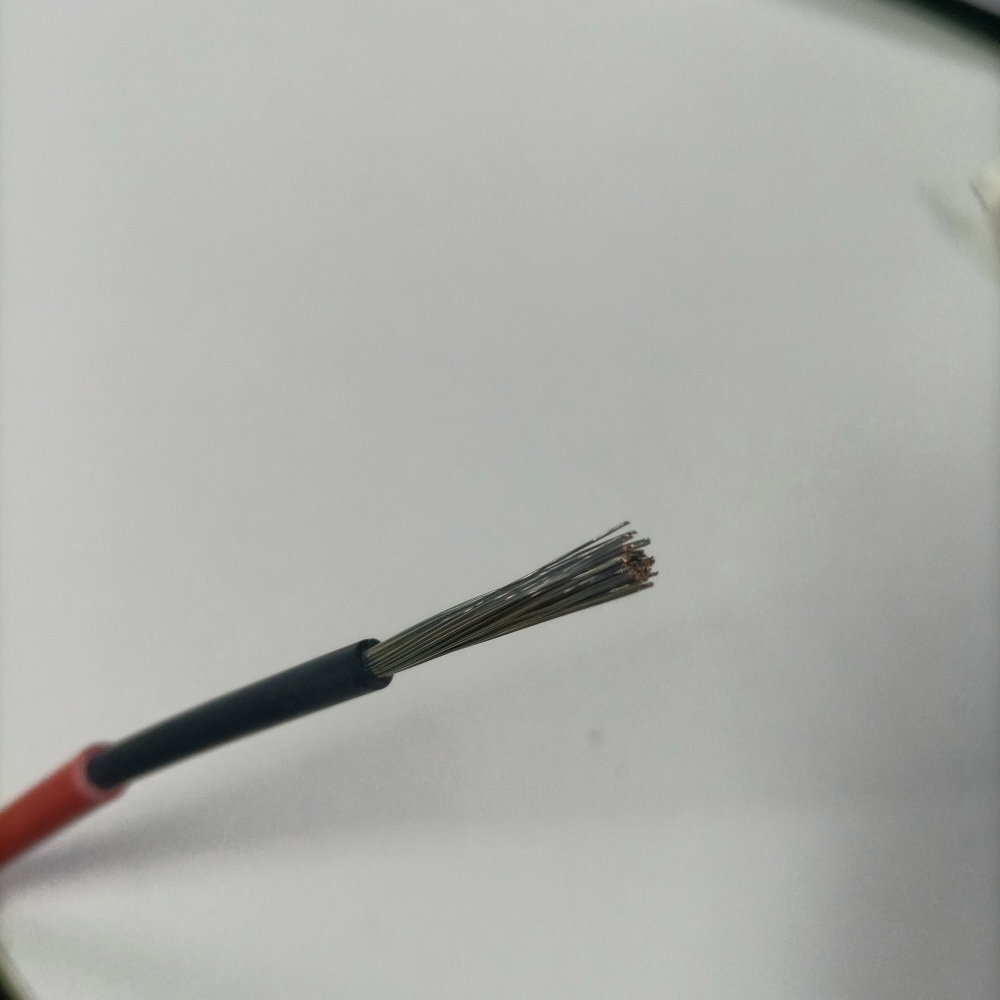

Bending radius: ≥4D when the outer diameter is ≤10mm, ≥6D when ≥10mm, convenient for installation in complex environments.

Tensile strength: ≥15N/mm², can withstand the deadweight load when laid vertically.

Abrasion resistance: passed DIN VDE 0472-805 standard, the insulation layer is not damaged after 5000 frictions.

Environmental adaptability

UV resistance: passed ISO 4892-3 standard, performance degradation ≤10% after 2000 hours of accelerated aging.

Oil resistance: passed IEC 60811-404 standard, insulation resistance retention rate ≥90% after immersion for 72 hours.

Salt spray resistance: passed IEC 60068-2-11 standard, no corrosion after 1000 hours of salt spray test.

4. Application scenarios of PV cable

Internal connection of photovoltaic power station

Series/parallel cables between components to reduce power loss caused by uneven insulation (actual loss reduced by 15%).

String to inverter connection, adapt to outdoor environment of -40℃ to +120℃.

Distributed photovoltaic system

Rooftop photovoltaic array wiring, LSZH model meets the building fire protection code (such as GB 8624-2012 B1 level).

Agricultural photovoltaic greenhouse, chemical corrosion resistance adapts to the pesticide spraying environment.

Energy storage system

The battery pack is connected to the inverter, and the cross-linked polyolefin insulation material extends the service life to more than 25 years.

Floating photovoltaic power station, water resistance passes the IEC 60227-2 standard.

Special environment application

Desert photovoltaic power station, anti-sand erosion performance passes the DIN 53516 standard.

High altitude areas (≥4000m), low temperature bending performance passes the GB/T 2951.14 standard.

5. Suitable for buyer analysis

Solar panel cable target customer group

Photovoltaic EPC companies: need to pass the acceptance of GB 50797 "Photovoltaic Power Station Design Code", uniform insulation cable can reduce the subsequent maintenance cost.

Inverter manufacturers: require the cable to be compatible with the equipment and reduce the contact resistance (measured contact resistance ≤0.5mΩ).

Export-oriented enterprises: Products must pass international certifications such as UL 4703 and TÜV 2PfG 2642 to enter the European and American markets.

Related Keywords

Related Keywords