Multicore Shielded Control Flexible Cable

- Min. Order:

- 1 Meter

- Min. Order:

- 1 Meter

- Transportation:

- Ocean, Land

- Port:

- Shenzhen, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land |

| Port: | Shenzhen,Hongkong |

Product Description

Product Description

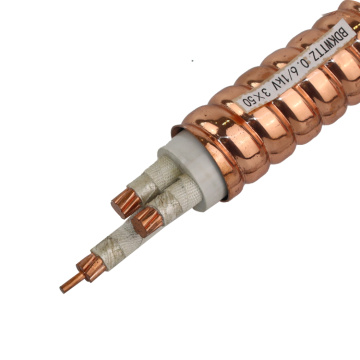

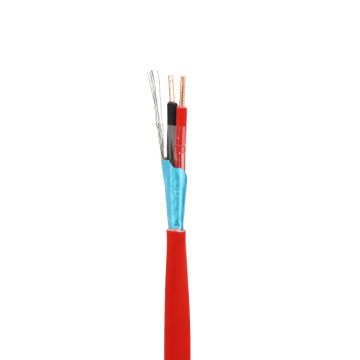

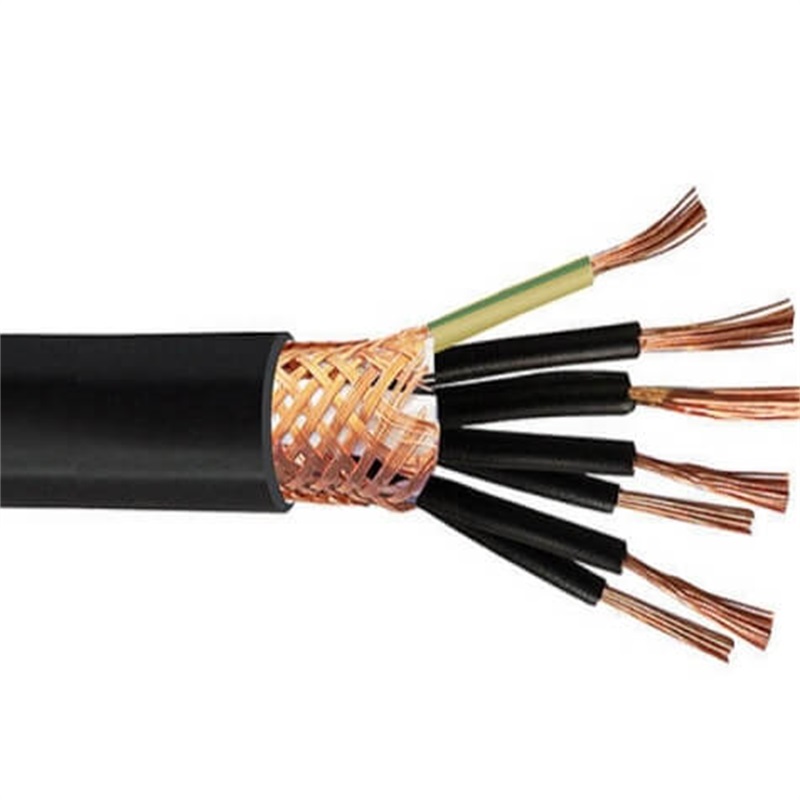

Multicore Shielded Control Flexible Cable is a special cable designed for dynamic environments. Its core structure includes multiple insulated conductors, metal shielding layers and flexible sheaths. The shielding layer (such as copper wire braiding and aluminum tape wrapping) isolates electromagnetic interference, and the flexible sheath (such as polyethylene and polyvinyl chloride) ensures mechanical stability under frequent bending. It is suitable for industrial robots, automation equipment and other scenarios that require high anti-interference and movement flexibility.

Data transmission characteristics of Control Cable

High-frequency anti-interference capability

The shielding layer can attenuate external electromagnetic interference (EMI) by 80-90dB (10MHz-1GHz frequency band) to ensure signal integrity. For example, in the welding scene of industrial robots, arc interference can be effectively suppressed, and the bit error rate is less than 10⁻¹².

Typical application: 100MHz Category 5e shielded twisted pair (STP) supports Gigabit Ethernet, with near-end crosstalk attenuation ≥45dB, meeting low-latency communication requirements.

Flexible performance and life of Flexible Cables

The bending radius can reach 6-10 times the cable diameter, and the bending life exceeds 10 million times (for example, the signal attenuation change of Luxshare Technology's 224G DAC cable under the 27AWG specification after the bending test is less than 0.5dB).

The elastic support layer design (such as the corrugated copper tape in the patent) can disperse the bending stress and avoid cracking of the insulation layer.

High-speed transmission and low loss

Supports a single-channel rate of 224Gbps (such as 800G/1.6T high-speed copper cable), with a total bandwidth of 1.6Tbps, meeting the explosive data needs of AI servers and HPC clusters.

Using low-loss materials (such as ethylene fluoride insulation), the transmission attenuation of 100 meters is less than 5dB (100MHz frequency band).

Model differentiation method

Structural classification

By shielding method:

Copper wire braided shielding (coverage ≥80%): suitable for high-frequency interference scenarios (such as 5G base stations).

Aluminum tape wrapping shielding: low cost, anti-low-frequency interference (such as industrial motor control).

Combined shielding (copper wire + aluminum tape): taking into account both high and low frequency interference (such as medical imaging equipment).

According to conductor specifications:

AWG12-22: thin wire diameter supports high frequency transmission (such as 224G DAC uses 22AWG).

Thick wire diameter (AWG18-22): carries large current (such as robot power cable).

Performance classification

Cat5e/Cat6/Cat7: divided by transmission frequency (100MHz-600MHz), Cat7 supports 10Gbps/100m transmission.

Flame retardant grade:

CM (general flame retardant), CMR (vertical combustion), CMP (low smoke and halogen-free), meeting different building safety standards.

Application scenario identification

Industrial grade (Industrial): The sheath is temperature-resistant from -40℃ to +105℃, and is UV-resistant and oil-resistant (such as automobile production lines).

Medical grade (Medical): biocompatible sheath, radiation-resistant design (such as CT scanner cables).

Production process analysis

Conductor manufacturing

Copper rod drawing: continuous drawing through a round carbide wire drawing die, wire diameter control accuracy ±0.001mm.

Annealing treatment: soften the conductor and improve flexibility (such as hydrogen annealing furnace, temperature 400-600℃).

Insulation and shielding layer processing

Insulation layer extrusion: physical foamed polyethylene (PE) is used, with a dielectric constant of ≤2.3 to reduce signal attenuation.

Shielding layer weaving: high-speed weaving machine (speed ≥2000rpm) achieves copper wire coverage ≥85%, shielding effectiveness ≥60dB (10MHz).

Sheath molding and testing

Sheath extrusion: TPU material has a bending resistance of >50 million times and a tear resistance of ≥50N/mm.

Finished product testing:

Bending test: bending radius 5D, insulation resistance >1GΩ after 10 million cycles.

Electromagnetic compatibility test: in accordance with IEC 62153-4 standard, crosstalk attenuation ≥40dB (100MHz).

Shielded Control Cable CVV-S CY LiYCY's core application scenarios

Industrial automation

Robot joints: Transmit motor control signals and sensor data. For example, Kuka robots use Cat7 shielded cables, which support 10Gbps/10m transmission.

CNC machine tools: Anti-interference design ensures processing accuracy (such as Fanuc system error <0.001mm).

Data centers and communications

High-speed interconnection: 800G/1.6T DAC/ACC cables replace optical fibers, reducing costs by 60% and power consumption by 40%.

5G base stations: Shielded cables connect AAU and BBU to suppress adjacent frequency interference (such as Huawei's Massive MIMO system).

Special environments

Medical equipment: Low-noise shielded cables are used for MRI and ultrasound imaging, with a 30% increase in signal-to-noise ratio (SNR).

Aerospace: Lightweight shielded cables (40% weight reduction) meet satellite communication needs (such as the Starlink project).

Related Keywords

Related Keywords