Fire Resistant Power Cable Halogen-Free

- Min. Order:

- 5000 Meter

- Min. Order:

- 5000 Meter

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

Product Description

Product Description

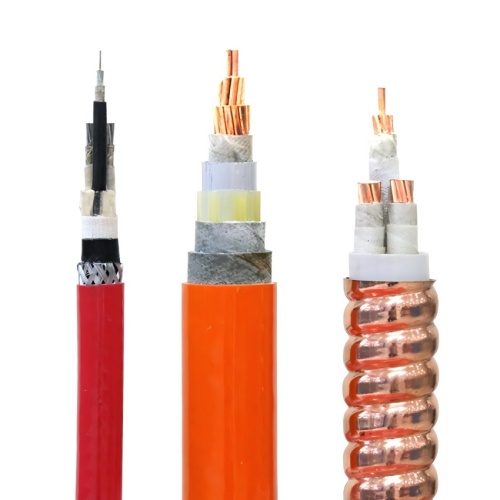

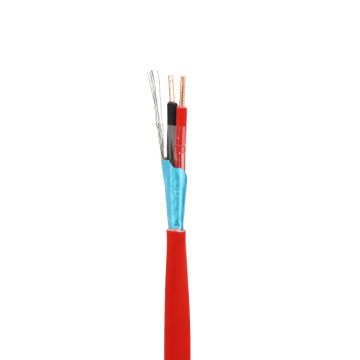

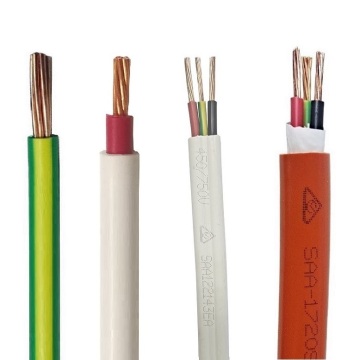

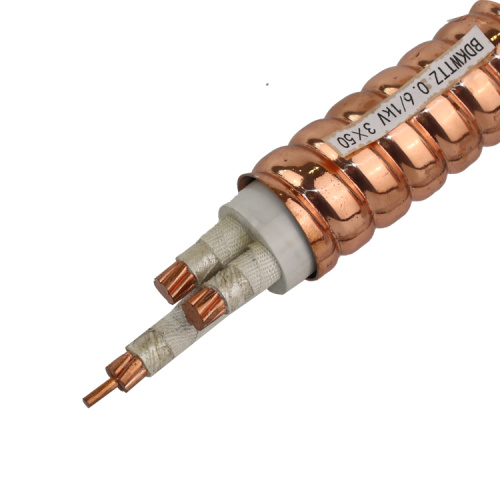

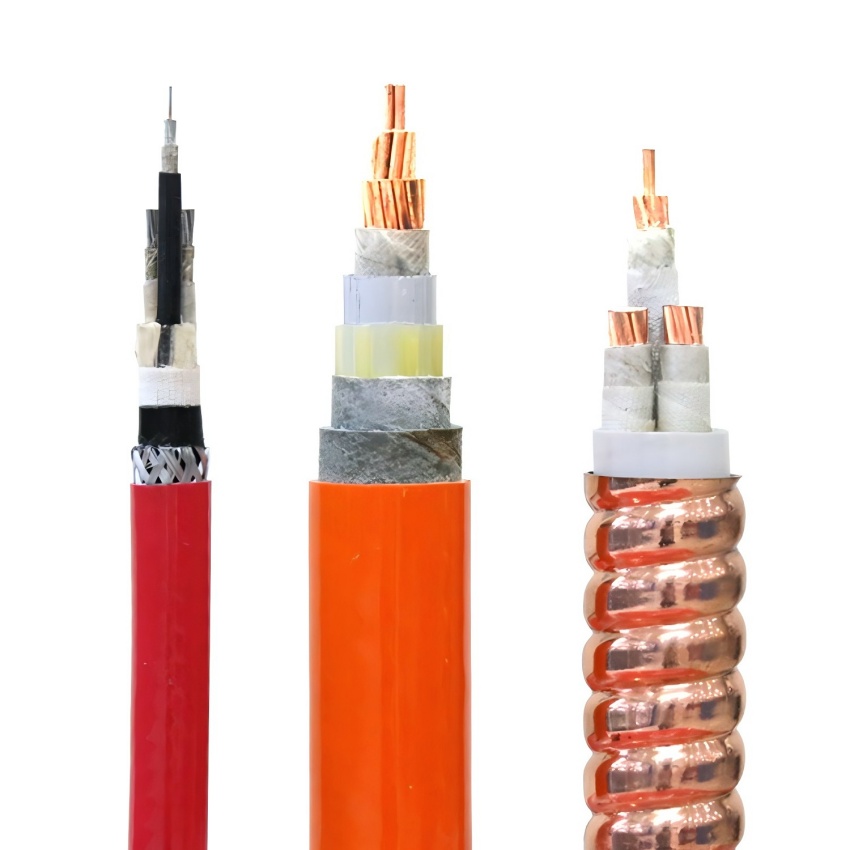

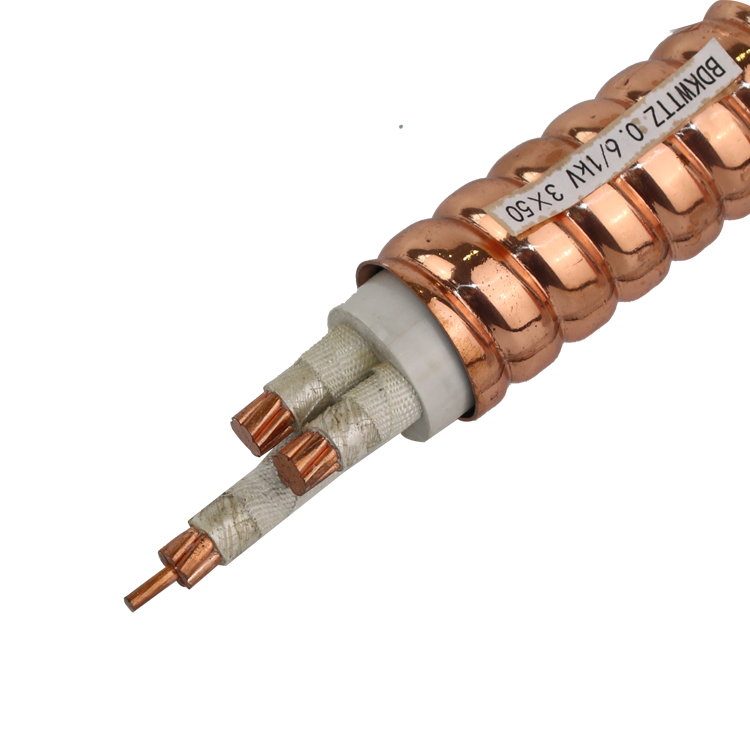

Fire-resistant halogen-free power cable is a special cable designed for fire scenes, using halogen-free materials (such as cross-linked polyolefin XLPO) as insulation and sheath.

1.Core characteristics of Fire Resistant Cable

Fire resistance

Tested according to GB/T 19216.21 or IEC 60331 standards, it can maintain line integrity for more than 90 minutes in a 750℃~1000℃ flame to ensure emergency power supply.

Fire resistance grades are divided into Class A (950℃~1000℃/90 minutes) and Class B (750℃~800℃/90 minutes) to meet the needs of different scenarios.

Halogen-free and low-smoke characteristics

During combustion, the smoke transmittance is ≥60%, the pH value is ≥4.3, and the conductivity is ≤10μS/mm, which reduces the release of toxic gases and facilitates escape and rescue.

It complies with GB/T 17650.2 and GB/T 17651 standards and is suitable for confined spaces.

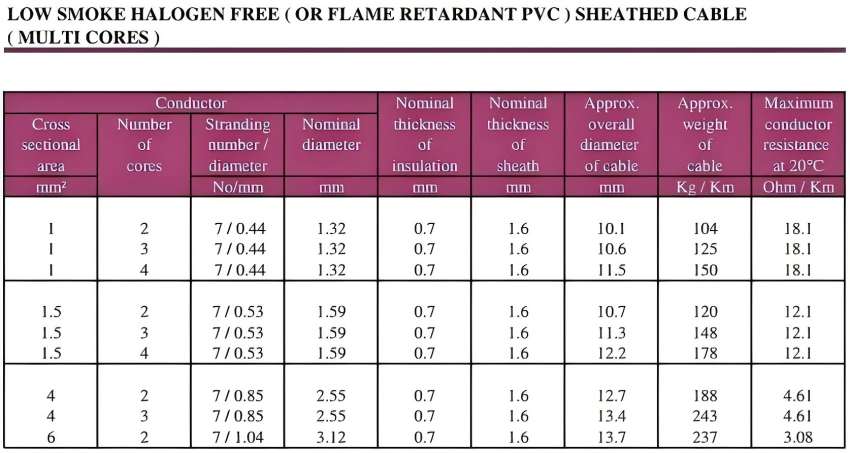

Electrical and mechanical properties

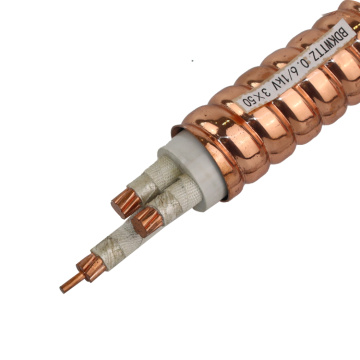

Rated voltage: 0.6/1kV, long-term working temperature 90℃, short-term temperature resistance 120℃~150℃.

Conductor resistance: ≤5.09Ω/km at 20℃ (4.0mm² model), tensile strength retention rate ≥70% (after high temperature aging).

Bending radius: ≥4D when outer diameter <25mm, ≥6D when ≥25mm, to avoid installation damage.

Key data and certification standards of Fire Rated Cable

Fire resistance time: 90 minutes for Class A, 90 minutes for Class B (flame temperature difference).

Flame retardant grade: A/B/C in accordance with GB/T 18380.3, Class A has the best flame retardant performance.

Smoke density: light transmittance ≥60%, much higher than the 20%~30% of ordinary cables.

Environmental protection indicators: RoHS certified, free of heavy metals such as lead and cadmium, and in compliance with EU REACH regulations.

International certifications: TUV, CE, UL, etc., suitable for global markets.

Application scenarios of Fire Proof Cable

Fire emergency system

Power supply for fire elevators, emergency lighting, and fire alarm devices to ensure normal operation of equipment during fire.

Case: When wiring fire passages in high-rise buildings, fire-resistant cables and ordinary cables are mixed and laid, independent bridges are required for isolation.

Places with dense crowds

Hospitals, theaters, shopping malls, stations, etc., halogen-free and low-smoke characteristics reduce the risk of secondary disasters caused by fire.

Data: In a fire in a large shopping mall, halogen-free cables shortened the evacuation time by 30%.

Industrial high-temperature environment

Steel mills, chemical workshops, nuclear power plants, etc., withstand short-term high-temperature shocks (such as polyimide insulated cables with a temperature resistance of 400°C).

Case: The blast furnace control cable of a steel plant adopts a fire-resistant and halogen-free design, reducing the failure rate by 80%.

Rail transportation

Subway tunnels and high-speed rail carriage wiring meet the EN 50264 standard and are resistant to mechanical shock and vibration.

Maintenance and maintenance of Fire Wire Cable

Regular inspection

Check the appearance of wear and cracks every quarter, focusing on joints and bends.

Use an infrared thermal imager to detect abnormal temperature rise and prevent local overheating.

Cleaning and dust prevention

Use a soft brush to clean dust, avoid using chemical cleaners, and prevent corrosion of the insulation layer.

Case: A data center caused a short circuit due to dust accumulation in the cable. The failure rate returned to zero after regular cleaning.

Moisture and rodent prevention

Store in a dry and ventilated environment and seal with plastic bags or tape.

Install cable sheaths or rodent-proof boards to avoid bite damage.

Avoid excessive bending

Follow the standard bending radius during installation to prevent the insulation layer from peeling off.

Tools: Use a bending aid to ensure radius compliance.

Regular insulation testing

Conduct DC voltage tests (such as 2.5kV/1min) or AC withstand voltage tests every year to ensure that the insulation resistance is ≥100MΩ.

Suitable for buyers

Target customer groups

Building developers: Fire wiring for high-rise residential buildings and commercial complexes must meet GB 50016 "Building Design Fire Protection Code".

Industrial users: High-temperature workshops of steel and chemical companies need to withstand extreme environments.

Government projects: Public facilities such as subways, airports, and hospitals must pass fire inspection.

Export-oriented enterprises: Products must comply with IEC and UL standards to enter the European and American markets.

Related Keywords

Related Keywords