PDLC Film Smart Film Switchable Film for Offices

-

$65.001-99 Square Meter

-

$50.00≥100 Square Meter

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen China |

|---|---|

| Supply Ability: | Ten Thousand Square Meters Per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | EXW,FOB,DDP,DDU,Express Delivery |

| Certificate: | CE, RoHS, FCC &SGS |

| HS Code: | 9013809000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen |

Product Description

PDLC Film Smart Film Switchable Film for Offices

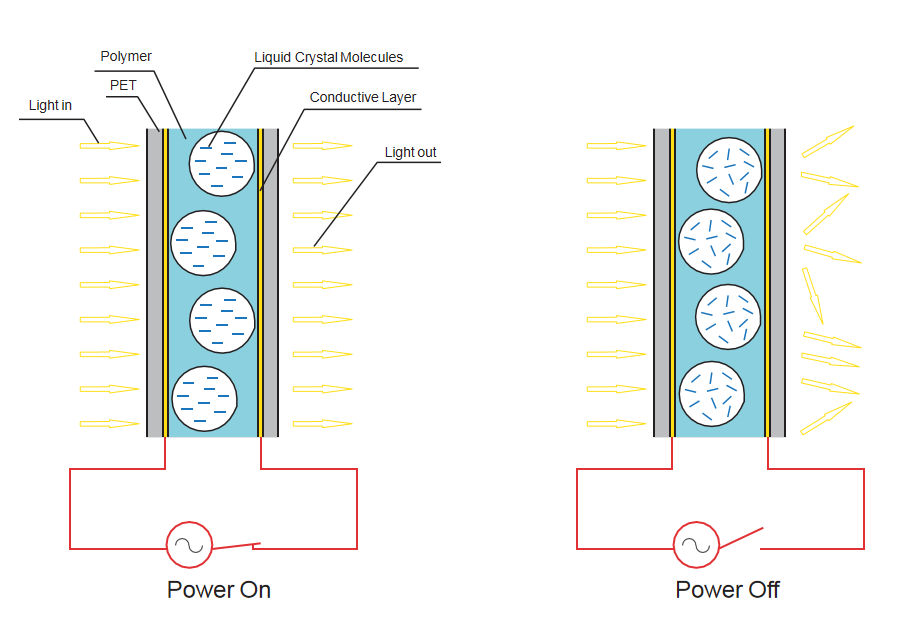

Intelligent electronically controlled Pdlc Film Glass is a laminated glass, which is a layer of liquid crystal film (commonly known as PDLC Film Roll, liquid crystal film) sandwiched between two layers of glass. forming. Considering the temperature resistance and pressure resistance of the liquid crystal film in the intelligent electronically controlled dimming glass during the production process, it is not suitable for high temperature and autoclave processing. Glass is an ancient building material that has been around since ancient Egypt

Several processing and production methods of dimming glass are explained in detail:

1. One-step solid-air forming method. Its mechanical tools are simple in structure, but there are only a handful of mechanical tools that can make dimming glass. The processing technology seems to be simple, but in the actual operation process, the temperature control accuracy is very high, and there will be a phenomenon of waste products. It is bubbles, glue opening, and haze. Due to the high consumption cost of dimming glass, the processing rejection rate cannot exceed 1%, so non-standard enterprises and enterprises whose technical ability cannot achieve precise control generally dare not use this method to consume dimming glass. At present, there are very few domestic manufacturers that master the essence of "one-step" dimming glass processing. However, the dimming glass waste made by this method has a long service life and relatively unchanged performance. Copper indium gallium selenide thin-film solar cells can be widely used in remote mountain power stations, agricultural and photovoltaic complementary projects, fishing and photovoltaic complementary projects, etc. Transportation and other fields

2. Process with autoclave. The previous process of autoclave processing is actually similar to one-step processing, and the autoclave is used for high pressure and high temperature molding in the later stage. Use banana water to fire doors and windows. It is an industrial agent used to remove paint, and it is easy to buy (where paint is sold). The method is also the same as alcohol acetone. Autoclave processing can effectively prevent However, the disadvantages are also obvious. Because the pressure of the glass formed by the autoclave is twice that of the one-step vacuum forming, and the conductive film of the first interlayer material of the dimming glass will be broken due to the large shrinkage rate. The increase in resistivity greatly shortens the function and service life of the dimming glass waste. Glass bottles generally have rigid signs, and the signs are also made of mold shapes. Smart Glass Window Film. Magic Glass Windows, Smart Glass For Hotel, Grey Smart Film

The mechanical tools used for dimming glass by the autoclave molding method must be public, and it is accurate and suitable for the characteristics of PDLC Smart Glass. Unfortunately, few domestic manufacturers use it for public use, and most of them are mixed with conventional laminated glass. It cannot guarantee the parameter requirements of the dimming glass, and it is easy to damage the mechanical tools. PDLC Smart Film Price, Get Smart Film, PDLC Smart Film for Sale

It uses two pieces (or three pieces) of glass to make high-cost air-tight composite adhesive, and bond the glass pieces to the aluminum alloy frame containing desiccant, resulting in high-efficiency sound insulation and heat insulation glass.

3. The water bath method is to immerse the sealed fixture in a 100-degree water tank. The temperature of various processing processes is accurate and uniform, but the manufacturing of the fixture is very difficult, as long as Japanese manufacturers accept it.

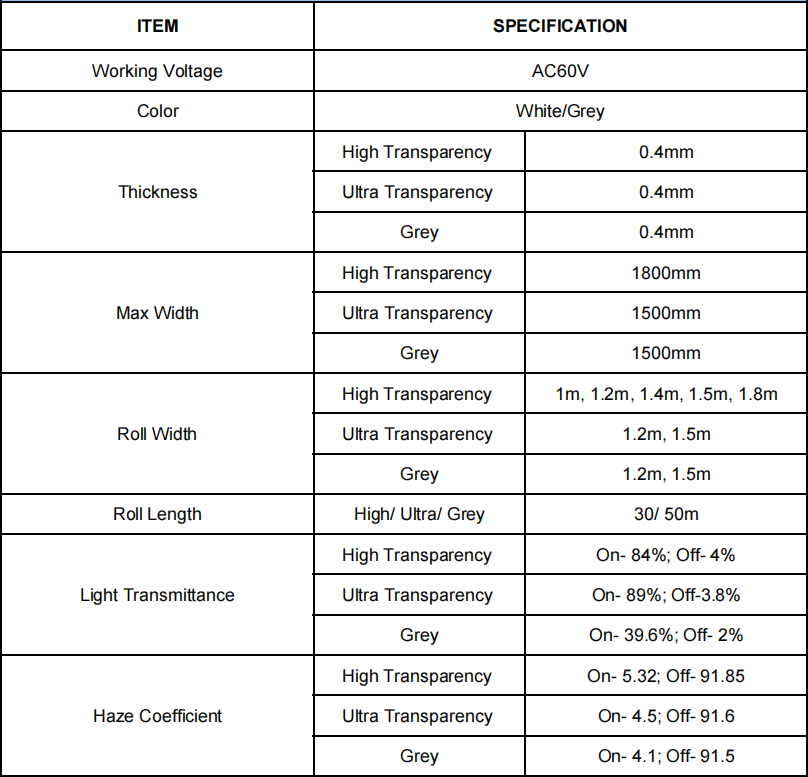

Product Parameters

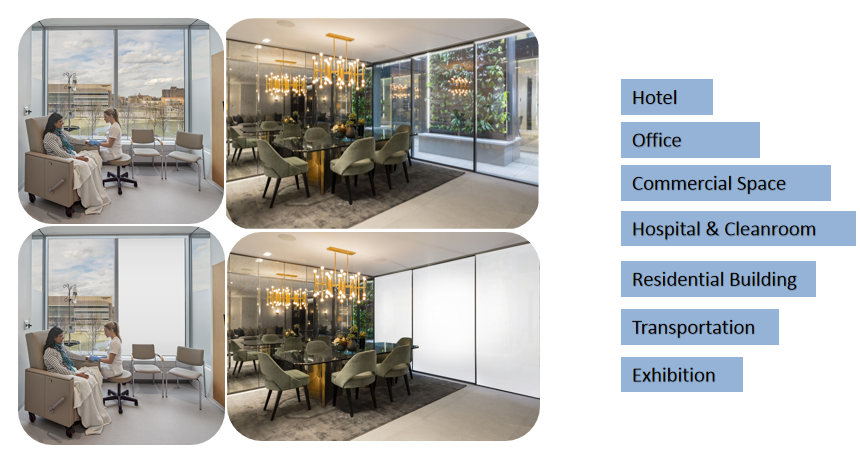

Application

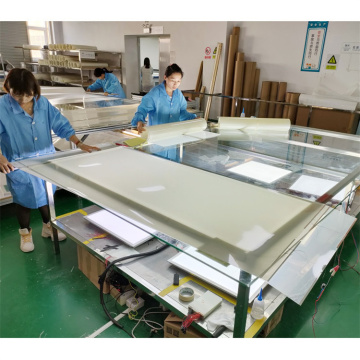

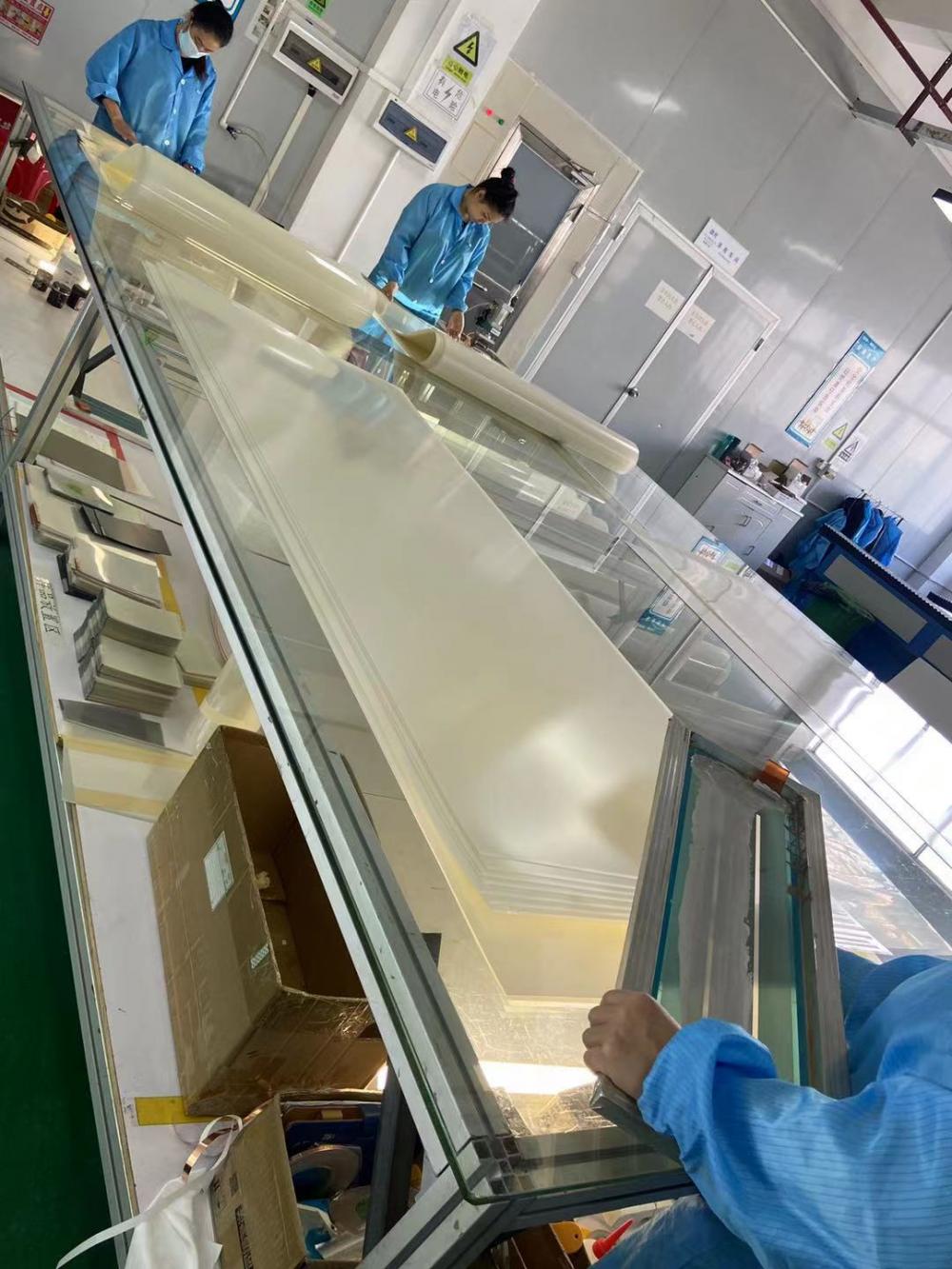

Factory

4.5m Full Auotmatic Smart Film Cutting Machine

Smart Film Pieces

Work Table

Make Busbar

Goods Shipping

Related Keywords