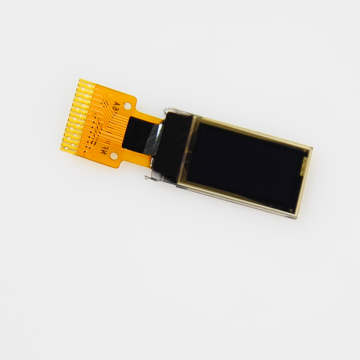

0.96 Inch TFT LCD display

- Min. Order:

- 3000 Piece/Pieces

- Min. Order:

- 3000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | more |

| Supply Ability: | strong |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

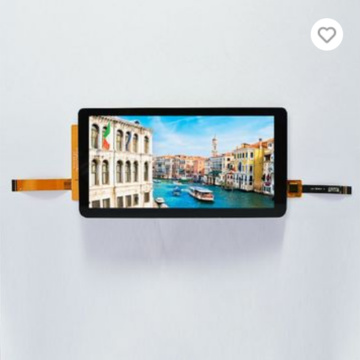

The TFT screen is equipped with a special light pipe on the back of the liquid crystal, which can actively control various independent pixels on the screen. This is the origin of the so-called active matrix TFT (active matrix TFT), which can greatly improve the response time. Generally speaking, the response time of TFT is relatively fast, about 80 milliseconds, while STN is 200 milliseconds. If improvement is needed, flicker will occur Passive matrix OLED. And because the TFT is an active matrix LCD, it can memorize the arrangement of the liquid crystal, and it will not return to its original state immediately after the current disappears Organic Light-Emitting Diode Display.

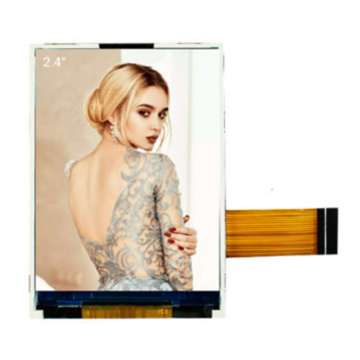

The display of the TFT display adopts the back-transparent illumination mode-the assumed light source path is not from top to bottom like TNLCD, but from bottom to top 0.96inch OLED. This method is to set a special light pipe on the back of the LCD, and the light source penetrates upward through the lower polarizer when irradiated. Since the upper and lower interlayer electrodes are changed to FET electrodes and common electrodes, when the FET electrodes are turned on, the performance of the LCD molecules will also change, and the purpose of display can be achieved through light shielding and light transmission. The response time is greatly improved to about 80 milliseconds. Because it has higher contrast ratio, richer colors and faster screen update frequency than TN-LCD, TFT is commonly known as true color 0.42-1.3 inch OLED.

Compared with DSTN, the main feature of TFT-LCD is to configure a semiconductor switching device for each pixel. Because each pixel can be directly controlled by dot pulses. Therefore, each node is relatively independent and can be continuously controlled. This design method not only improves the response speed of the display screen, but also accurately controls the display gray level, which is why the color of TFT is more realistic than DSTN.

TFT also improves the blurring of STN flicker (water ripple) and effectively improves the ability to play dynamic images. Compared with STN, TFT has excellent color saturation, recovery ability and higher contrast, but the disadvantage is high power consumption and high cost.

TFT LCD screen technical characteristics

TFT technology was developed in the 1990s. Large-scale semiconductor full integrated circuit manufacturing technology using new materials and new processes is the basis of liquid crystal, inorganic and organic thin-film electroluminescence (EL and OEL) flat panel displays. TFT is a non-single wafer such as glass or plastic substrate (of course, it can also be on a wafer). Various thin films required for manufacturing circuits are formed through sputtering and chemical deposition techniques, and large-scale semiconductor integrated circuits (LSIC) are manufactured through thin-film processing. The use of non-single crystal substrates can greatly reduce costs. This is an extension of traditional large-scale integrated circuits to large-area, multi-function, and low-cost directions. It is more difficult to manufacture TFTs that control the switching performance of pixel (LC or OLED) on a large-area glass or plastic substrate than it is to manufacture large-scale integrated circuits on silicon. The requirements for the production environment (purification degree is 100), the requirements for the purity of raw materials (the purity of electronic gas is 99.9999985%), and the main requirements for production equipment and production equipment exceed semiconductor technology.

Related Keywords