High-quality vertical tin furnace

- Transportation:

- Ocean

- Port:

- Yantian Port, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300 units/year |

| Supply Ability: | Sufficient supply |

| HS Code: | 8515190010 |

| Transportation: | Ocean |

| Port: | Yantian Port, Shenzhen |

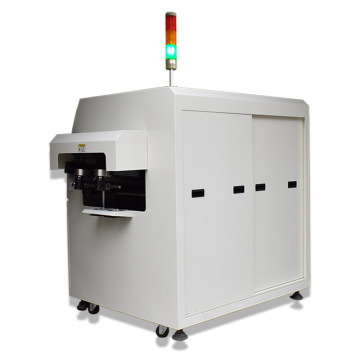

High-quality vertical tin furnace

|

Model: MJ-4530 vertical |

Tin pot specification: 450* 300*50mm |

|

Melting tin volume: 47KG |

Temperature range: 0-600 degrees |

|

Power: 4.2KW |

Dimensions: 520*370*600mm |

|

Voltage power: AC220V 4.2KW |

Control mode: digital display, automatic constant temperature |

product details

Pure titanium tin pot

The tin pot is made of imported military-grade high-quality titanium plate, corrosion-resistant, acid-resistant, non-stick tin, imported

Ceramic heating element and thermocouple, long service life and energy saving

Dual temperature digital display

The thermostat adopts PID self-tuning technology, with a temperature error of ±2°C, and has a temperature compensation function to ensure that the displayed temperature is consistent with the actual temperature

Appearance chassis

The appearance is made of 1.5mm iron plate, sturdy and durable, and the surface is sprayed with paint process, which is thick and firm

Automatic switch

You can set the power on and off time at eight times a day within a week, cycle every week, and start the preheating in advance to save the tin melting time

Casters

Use casters to move, convenient to change the working place, and can be fixed by braking when it is not moving

Matters needing attention>

1. Input voltage: AC220V 50HZ

2. Be sure to ground before use, and it is forbidden to work without wires

3. It is recommended to set the first melting temperature to 80-150 degrees. After the tin starts to melt, slowly adjust the temperature to the required temperature. It takes about 20-30 minutes for the temperature to reach the set temperature. The height of the molten tin should be about 5mm away from the top of the tin furnace. After the tin is completely melted, you can do the soldering work before leaving the power supply to avoid accidents

Daily maintenance>

1. Every day, after the work is completed, be sure to clean the oxides in the tin bath to keep the tin bath and the tin furnace shell clean for a long time

2. When adjusting the temperature parameters and pressing the switch, be careful not to use too much force to avoid damage to the switch. The tin in the tin bath should be kept in sufficient amount, because the temperature sensing point is about the middle height of the tin bath, too little molten tin will cause temperature detection deviation

Free warranty period: 12 months

Warranty scope: all accessories of the whole machine

Warranty method: telephone communication, mail accessories guide replacement; door-to-door service

Installation and debugging: on-site installation and debugging or remote assistance in installation and debugging

After-sales response time: mail accessories (sent within 1 hour), door-to-door] service (departure within 4 hours of working time)

Workshop shots

Item display

About delivery

All the equipment of the company includes freight and distribution fees, excluding the cost of going upstairs, depending on the distance, choose logistics consignment or door-to-door delivery

On-site installation and commissioning

The company is responsible for distribution, and there are professional engineers on-site installation, commissioning, training, or guidance and assistance through remote video or telephone

1 year warranty

After-sales promises that all parts of the wave soldering machine are guaranteed for one year, except for human problems

Lifetime service

The company provides life-long maintenance, paid service, only labor costs and material costs

Preparation before installation and commissioning

1. Door-to-door time: within 2 working days after all the following work is ready, special circumstances will be discussed separately

2. Logistics transportation: After receiving the goods, customers who choose logistics transportation must first place the equipment and prepare all the following materials

3. Home delivery: Customers who choose home delivery need to reserve space in advance to prevent equipment and prepare all the following materials

Material preparation:

1. Power connection: lead the power cord to the device according to the requirements of the device, leaving a length of more than 3 meters to connect to the device

2. Air connection: If there is an air source in the workshop, lead the air pipe to the side of the equipment, leaving a length of more than 3 meters to connect to the equipment. If there is no air source in the workshop, you need to prepare the air compressor in advance and prepare the necessary accessories

3. Tin bar: Prepare enough tin bars in advance according to the tin capacity requirements of the equipment, so that the master can directly melt the tin for on-site trial welding test and training when he comes to the door.

4. Flux: the flux that needs to be used when the product is ready for trial welding. At least 2 liters required for testing

5. Cleaning agent: the nozzle used to clean the flux, temporarily not used, it will not affect the debugging

Related Keywords