High-quality desktop immersion tin furnace

- Transportation:

- Ocean

- Port:

- Yantian Port, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300 units/year |

| Supply Ability: | Sufficient supply |

| HS Code: | 8515190010 |

| Transportation: | Ocean |

| Port: | Yantian Port, Shenzhen |

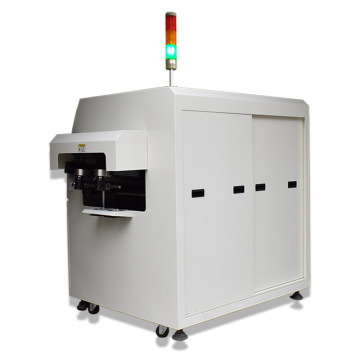

High-quality desktop immersion tin furnace

|

Model: MJ-ZD4530T |

Furnace size: 450* 300* 75mm |

|

Melting tin volume: 70KG |

Dimensions: 750*520*850mm |

|

Power: 5KW |

Control system: touch screen |

|

Drive motor: stepper motor |

Additional configuration: spray + foot switch |

Matters needing attention>

●The tin furnace installation must be grounded

●After the tin is completely melted, the soldering work can be done

●Turn on the power of immersion tin (do not turn on this switch before melting tin, so as to avoid misoperation and cause accidents)

●Used when the machine needs to stop the machine movement immediately when the machine fails. After pressing the emergency stop switch, all the actions of the machine will stop immediately to avoid harm to the human body and ensure the safety of the operator

Daily maintenance>

●Every day, when the work is finished, be sure to clean the oxide in the tin bath to keep the tin bath clean for a long time

●Regularly clean the titanium frame jigs that are covered with flux

●Regularly lubricate the motor and the screw rod to improve the life and reduce the noise

Company strength

Workshop shots

Item display

About delivery

All the equipment of the company includes freight and distribution fees, excluding the cost of going upstairs, depending on the distance, choose logistics consignment or door-to-door delivery

On-site installation and commissioning

The company is responsible for distribution, and there are professional engineers on-site installation, commissioning, training, or guidance and assistance through remote video or telephone

1 year warranty

After-sales promises that all parts of the wave soldering machine are guaranteed for one year, except for human problems

Lifetime service

The company provides life-long maintenance, paid service, only labor costs and material costs

Preparation before installation and commissioning

1. Door-to-door time: within 2 working days after all the following work is ready, special circumstances will be discussed separately

2. Logistics transportation: After receiving the goods, customers who choose logistics transportation must first place the equipment and prepare all the following materials

3. Home delivery: Customers who choose home delivery need to reserve space in advance to prevent equipment and prepare all the following materials

Material preparation:

1. Power connection: lead the power cord to the device according to the requirements of the device, leaving a length of more than 3 meters to connect to the device

2. Air connection: If there is an air source in the workshop, lead the air pipe to the side of the equipment, leaving a length of more than 3 meters to connect to the equipment. If there is no air source in the workshop, you need to prepare the air compressor in advance and prepare the necessary accessories

3. Tin bar: Prepare enough tin bars in advance according to the tin capacity requirements of the equipment, so that the master can directly melt the tin for on-site trial welding test and training when he comes to the door.

4. Flux: the flux that needs to be used when the product is ready for trial welding. At least 2 liters required for testing

5. Cleaning agent: the nozzle used to clean the flux, temporarily not used, it will not affect the debugging

Related Keywords