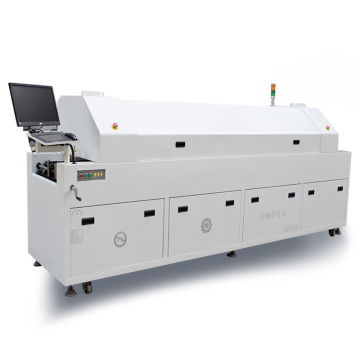

High quality six temperature zone reflow soldering

- Transportation:

- Ocean

- Port:

- Yantian Port, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 300 units/year |

| Supply Ability: | Sufficient supply |

| HS Code: | 8515190010 |

| Transportation: | Ocean |

| Port: | Yantian Port, Shenzhen |

High quality six temperature zone reflow soldering

Due to the continuous miniaturization of PCB boards of electronic products, chip components have appeared, and traditional soldering methods can no longer meet the needs. At first, only the reflow soldering process was used in the assembly of hybrid integrated circuit boards, and most of the components to be assembled and soldered were chip capacitors, chip inductors, mounted transistors and diodes. With the development of the entire SMT technology becoming more and more perfect, and the emergence of a variety of chip components (SMC) and mount devices (SMD), the reflow soldering process technology and equipment as part of the placement technology has also been developed accordingly, and its applications are becoming more and more extensive. Almost all electronic products have been applied

Features

① The heating system adopts Maijie SMT heating technology.

② Using imported high-current solid state relay non-contact output, safe and reliable, equipped with a special SSR radiator, the heat dissipation efficiency is greatly improved, and its service life is effectively prolonged.

③ The heating components adopt imported high-quality components to ensure the high stability and reliability of the system, and to ensure a long service life.

④ The modular design of the heating zone is convenient for maintenance and disassembly.

⑤ It has the functions of temperature tolerance, fault diagnosis, sound and light alarm.

⑥ Independent small circulation air transport design, upper and lower heating methods, good thermal compensation, high thermal efficiency, power saving, fast heating speed, suitable for welding of high-quality products such as BGA and CSP components. The special forced hot air circulation structure system makes the PCB and components heat evenly, with high efficiency and fast heating speed.

⑦ The air conveying system adopts advanced air duct design, with uniform air conveying and high heat exchange efficiency.

⑧ The preheating zone, the welding zone and the cooling zone are heated independently up and down, cycled and controlled independently. The temperature difference between adjacent temperature zones can reach up to 100℃, without temperature series. The temperature and wind speed of each temperature zone can be adjusted independently.

⑨ Using imported high-temperature motor to directly drive the hot air circulation, the hot air is well balanced, the operation is stable, the life is long, and the noise is low.

⑩ The power of each temperature zone is properly matched, and the temperature rises quickly. It takes about 15 minutes from room temperature to set working temperature. And has fast and efficient thermal compensation performance.

11 modular design, compact structure, easy maintenance.

12 The independent cooling zone ensures the required low temperature when the PCB board is out of the board.

13 The transmission system adopts a frequency conversion motor imported from Taiwan, with a 1:100 imported turbo reducer, running smoothly, with an adjustable speed range of 0-1500mm/min. 14 It adopts independent roller structure and flat support, combined with stainless steel mesh belt, runs smoothly, suitable for welding such as BGACSP.

15 Special stainless steel B-shaped mesh belt, durable and wear-resistant. Long-term use is not easy to change.

4. Installation and use conditions

<1>Working voltage: AC380V 50HZ three-phase five-wire system.

<2> Ambient temperature: 5~40℃;

<3>Relative humidity: not more than 85%RH;

<4>Power switch: air switch

<5> Installed power: 27KW

<6>The ground is flat, and there should be no strong vibration and corrosive gas in the surrounding environment.

5. Reflow soldering process

Printed board preparation-solder paste preparation-printing solder paste-mounting post-chip components-through reflow soldering-soldering completion-testing-shaping and trimming-completion

Company strength

Workshop shots

Item display

About delivery

All the equipment of the company includes freight and distribution fees, excluding the cost of going upstairs, depending on the distance, choose logistics consignment or door-to-door delivery

On-site installation and commissioning

The company is responsible for distribution, and there are professional engineers on-site installation, commissioning, training, or guidance and assistance through remote video or telephone

1 year warranty

After-sales promises that all parts of the wave soldering machine are guaranteed for one year, except for human problems

Lifetime service

The company provides life-long maintenance, paid service, only labor costs and material costs

Preparation before installation and commissioning

1. Door-to-door time: within 2 working days after all the following work is ready, special circumstances will be discussed separately

2. Logistics transportation: After receiving the goods, customers who choose logistics transportation must first place the equipment and prepare all the following materials

3. Home delivery: Customers who choose home delivery need to reserve space in advance to prevent equipment and prepare all the following materials

Material preparation:

1. Power connection: lead the power cord to the device according to the requirements of the device, leaving a length of more than 3 meters to connect to the device

2. Air connection: If there is an air source in the workshop, lead the air pipe to the side of the equipment, leaving a length of more than 3 meters to connect to the equipment. If there is no air source in the workshop, you need to prepare the air compressor in advance and prepare the necessary accessories

3. Tin bar: Prepare enough tin bars in advance according to the tin capacity requirements of the equipment, so that the master can directly melt the tin for on-site trial welding test and training when he comes to the door.

4. Flux: the flux that needs to be used when the product is ready for trial welding. At least 2 liters required for testing

5. Cleaning agent: the nozzle used to clean the flux, temporarily not used, it will not affect the debugging

Related Keywords