Portable Blender Pcba Electronics Assembly

-

$29.90≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is PCBA SMT?

I believe that many people are not unfamiliar with the electronics industry-related terms such as PCB circuit board, Surface-Mount (SMT) & BGA Assembly. These are often heard in daily life, but many people do not know much about PCBA patch processing. It is often confused with PCB. So what is PCBA patch processing? What is the difference between PCBA and PCB?

PCBA introduction:

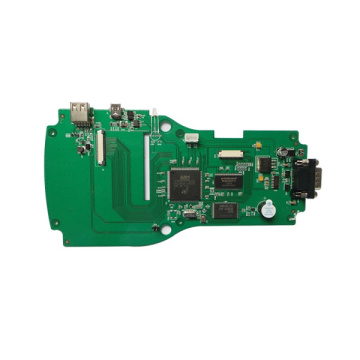

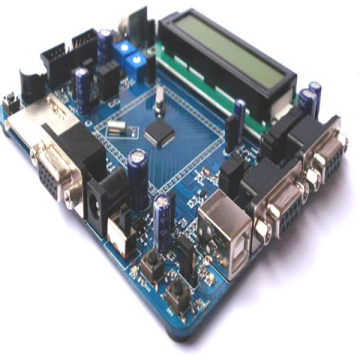

PCBA is the abbreviation of Printed Circuit Board + Assembly in English, which means that the empty PCB board passes through SMT and then passes through the entire PCBA Manufacturing process of Wave Solder for PCBA, referred to as PCBA.

The difference between PCBA and PCB:

From the above introduction, we can know that PCBA generally refers to a processing process, which can also be understood as a finished circuit board, which means that PCBA can be counted after all the processes on the PCB board are completed. The PCB refers to an empty printed circuit board with no parts on it.

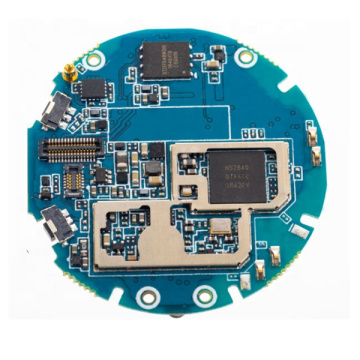

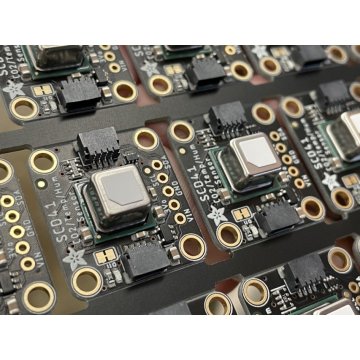

With the high-speed, high-performance, and ultra-miniaturization of electronic equipment, packaging technology has developed rapidly. Originality electronics IC packaging has developed towards multiple lead ends and narrow lead pitch, and bare chip (Bare Chip) packaging has also been put into practical use. Due to the advancement of these packaging technologies, new requirements are also put forward for the Printed Wiring Board (PCB) (to adapt to high-density packaging and high-speed requirements).

Previous electronic product manufacturers, to complete a complete circuit board production, usually need to purchase the PCB first, and then contact the patch manufacturer for patch processing. The process is very troublesome and costly. Nowadays, many manufacturers are willing to choose PCB manufacturers to process patches at the same time as PCBs, or let patch manufacturers replace PCBs. Both methods save a lot of trouble and speed up production efficiency. And PCBA manufacturers can realize these two fast and effective processing methods, purchase and patch correctly.

PCB procurement and patch processing are two different production methods. Many electronic manufacturers only specialize in one of them. This requires electronic product manufacturers to comprehensively consider the strength of the manufacturer when choosing a PCBA processing manufacturer, and choose rich experience and outstanding performance. Manufacturers who have completed the entire processing process.

Related Keywords