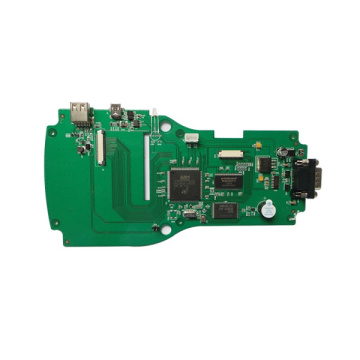

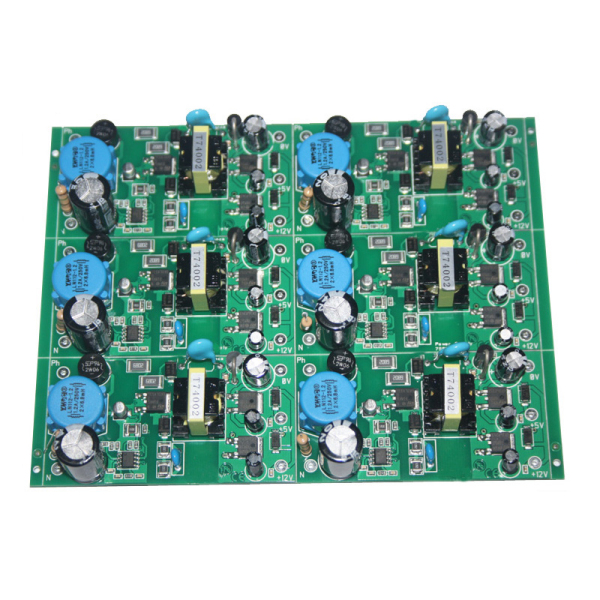

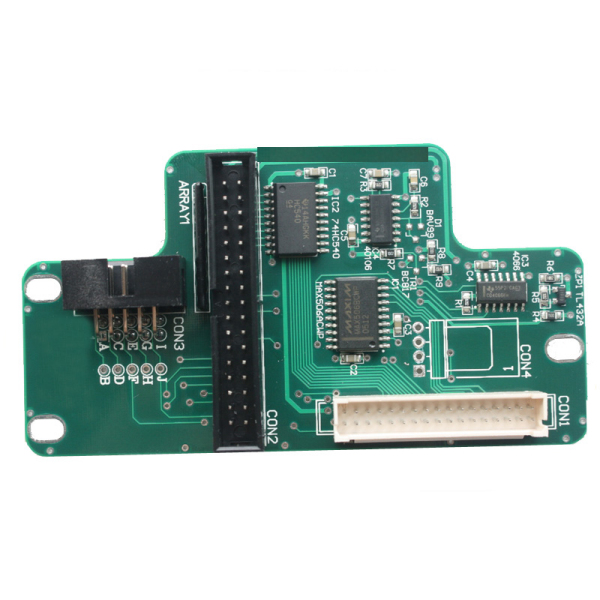

cnc machine prototype layout making pcb placa

-

$19.901-999 Piece/Pieces

-

$13.00≥1000 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

What is PCB prototype machine?

The two basic stages of developing electronic PCB products are: simulation and High Quality Prototype PCB Fabrication. Simulation; Although sometimes overlooked, it is done through software and its purpose is to verify whether the circuit design meets its performance and functional design standards. Electronic circuit simulation is a valuable tool because it eliminates the need to build unnecessary PCBs, and these PCBs have almost no chance to achieve design goals. Passing the simulation test is only the first step in electronic design, because the hardware device or PCB must also be tested. This type of test, called prototype, can be defined by purpose, process, and results.

Purpose

The purpose of High Quality Prototype PCB Fabrication is to build and test the physical implementation of functions, operations and designs. Structural integrity. The integrity of the structure represents pcb over 99.6% Satisfied rate and reliability, and is usually adjusted according to the expected use of the PCB.

handle

PCB prototyping is usually divided into three stages. Just as multiple simulations are usually required before final parameters are determined and the requirements are met, prototyping is cyclical and usually requires multiple iterations of PCB construction before finalization has been completed.

result

For each prototype iteration, an assembled PCBA is created and tested. The test results determine whether other iterations are needed. Usually, additional iterations mean redesigns or design changes, and new boards need to be built and tested. The final result of PCB prototypes can be used for the design of the circuit board in quiet or high-volume production, depending on the intended application of the circuit board.

Now that we have answered what PCB prototypes usually need to do, let's see if parallelization can be used to improve development.

Related Keywords