The temperature rise of PCBA

-

$20.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air, Others

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal |

|---|---|

| Incoterm: | FOB,EXW,FCA |

| Transportation: | Ocean,Land,Express,Air,Others |

| Port: | shenzhen |

What should we do if PCBA's temperature rises too high?

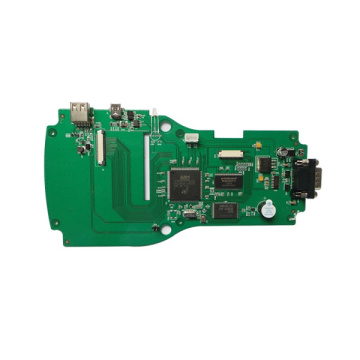

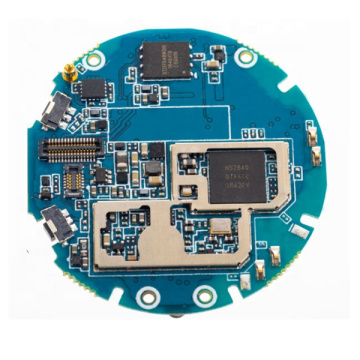

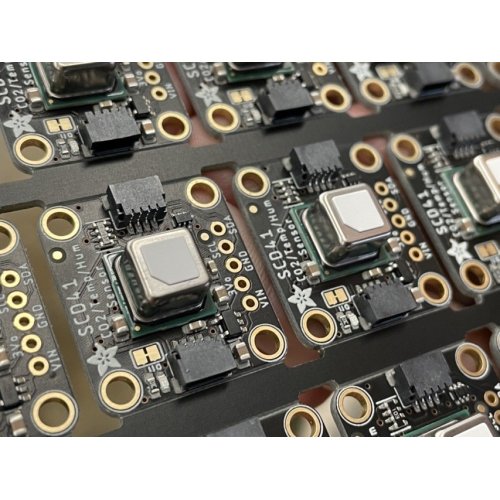

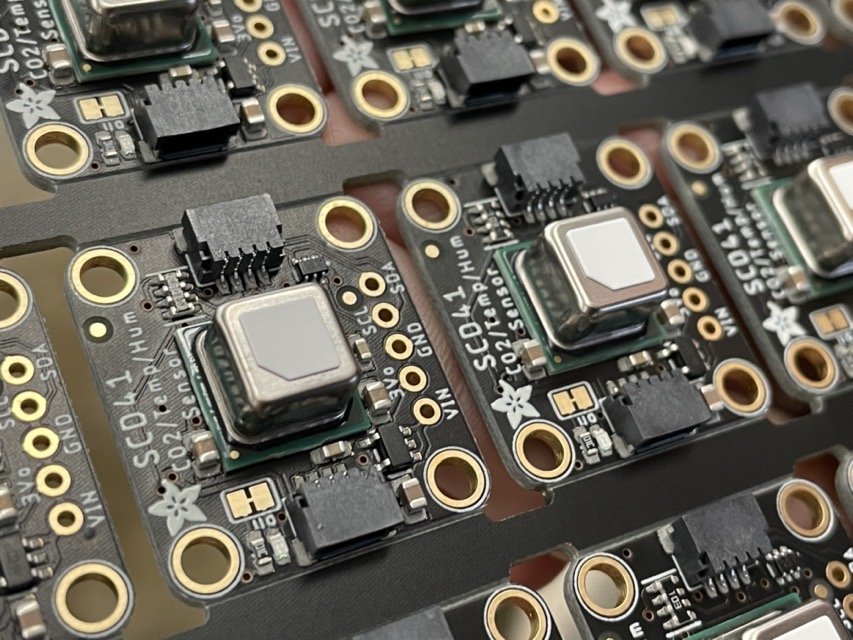

From the beginning of the design to the finished product, the circuit board has to go through many processes, such as component selection, schematic design, PCB design, PCB proofing production, debugging test, performance test, temperature rise test, etc., after a series of processes, the final result is For a circuit board with reliable performance and continuous operation, the temperature rise of the circuit board should not be too high. If it is too high, it will affect the life of the components and the performance of the circuit board.

The various components of the circuit board work are in different working states. Heat will be generated when working, and the internal temperature rise of the body. Therefore, the power consumption of the components is the direct source of the temperature rise. Of course, in addition to the components, there is also the ambient temperature. Therefore, reducing the internal temperature of the circuit board has become one of the issues that every engineer must consider when designing, so how to solve the temperature rise problem of the circuit board? Here are a few methods

1. Reasonable circuit board layout and trace design

This is one of the most important points to pay attention to. The circuit board has many components, and each component has a different temperature resistance. For example, some ICs work at 105°, relays work at 85°, etc., and the power consumption and heat generation are different. , The height is not the same, so the design should be fully considered:

①For a circuit board environment that does not have a fan cooling system, but only relies on air flow to take away heat, place the components reasonably, and avoid placing excessively high components at the air inlet. For example, place the components with more serious heat in the best position for heat dissipation. It can be here, but it’s best not to be too high

②For temperature sensitive devices, it is best to place them in the lowest temperature area, such as thermistors, because thermistors have great changes in temperature

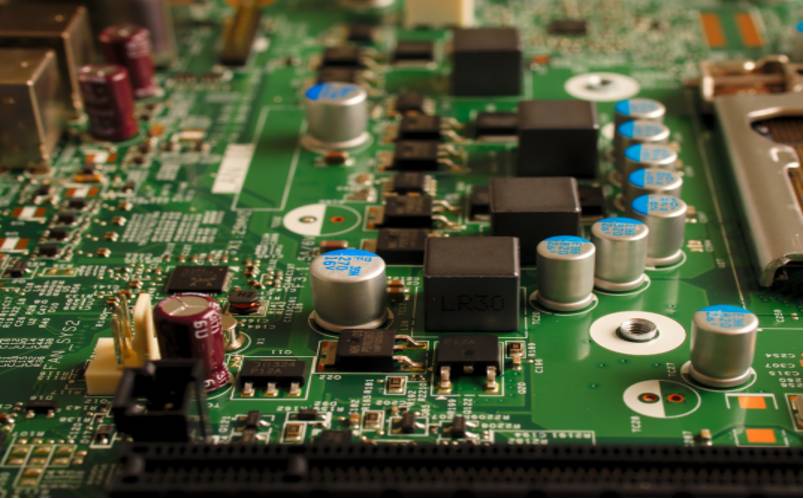

③The PCB circuit boards should not be placed together with severe heat, and they should be evenly distributed on the circuit board as much as possible. If there is a fan system to dissipate heat, it should be considered to be concentrated together and the heat should be close to the other side of all components. Moreover, the left and right components are best arranged in a vertical (horizontal) way, which is conducive to heat dissipation.

④For high-power devices, such as transistors, amplifiers, etc. can be placed on the edge of the circuit board, so as to reduce the radiation effect on the surrounding heat and temperature

2. Increase the fan cooling system

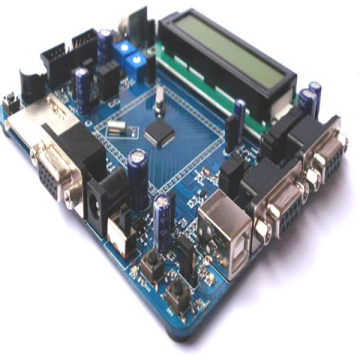

For large circuit boards, such as computers, induction cookers, inverters, UPS power supplies, charging piles and other circuit boards, there will generally be fan systems. Some fan systems are still smart and change the fan speed according to the temperature of the environment. When the temperature is not very high, the fan system Won't open.

3. Increase the copper foil area of the circuit board

The heat dissipation can be increased by increasing the copper foil area of the circuit board. For example, for high-current circuits, increase the copper foil when conditions permit, and place the soldering layer at the same time. If necessary, add tin to the soldering layer, so that the current is too large. The heat dissipation effect will be better

4. Increase heat sink and heat sink paste

For components with serious heat generation such as switch tubes, heat sinks can be added, and high thermal conductivity insulating silicone material heat dissipation paste can be added at the same time. This is a material with good thermal conductivity, and the heat sink makes the heat emitted by the components better conduction In the air, because of this, the high-frequency switching power supply basically uses a switch tube with a heat sink. When the output power of the 7805 we often use is very large, a heat sink must be added. The heat sink shown in the figure below is very large

5. Select components and circuit boards with higher temperature resistance

If due to limited space, the fan system and natural cooling capacity are limited, such as the charger of our mobile phone, the components inside are very hot in such a small space. In addition to the layout, use components with higher temperature resistance. It may also be a good method, but the cost may rise in this way, so a compromise must be considered. You can choose a PCB board with a higher temperature resistance, such as a glass fiber board.

Related Keywords