Hole PCB Assembly Copper 1OZ Lead Fee

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is the difference between PCB and SMT?

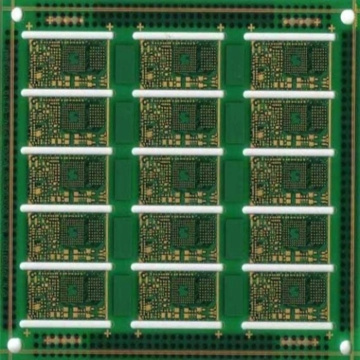

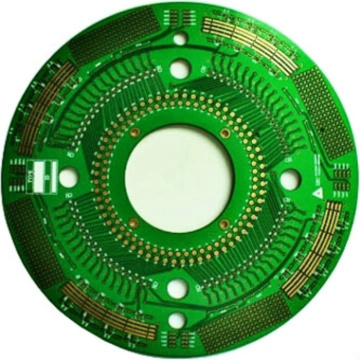

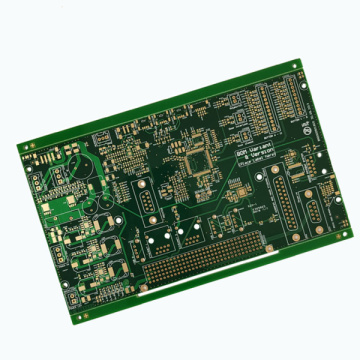

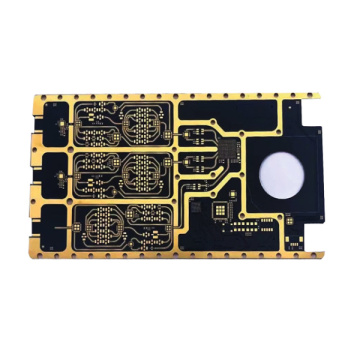

1. PCB, also known as buile-up printed board, is a necessary raw material for Surface-Mount (SMT) &BGA Assembly, and it is just a semi-finished product.

2. Turkey PCB Assembly is a circuit board assembly technology. It is the most popular process technology by buying PCB substrates and mounting Electronic Components on the PCB through technology.

3. PCBA Manufacturing is a complete processing service based on SMT, which increases the purchase of components,like Electronic Resistor and Capacitor,Electronic connectors and etc,and the subsequent testing and finished product assembly links. It is a service model that provides customers with one-stop service and is developed in the future. direction.

When an electronic product is processed, the order should be PCB→SMT→PCBA. PCB production is very complicated, while SMT is relatively simple. PCBA emphasizes one-stop service. Guangzhou Zhongyan Electronics www.gz-smt.com, is an electronic processing enterprise specializing in SMT chip processing, DIP common processing, PCBA packaging materials, PCB circuit board manufacturing, has many years of electronic processing experience, and advanced production Equipment and perfect after-sales service system. The company's SMT chip processing capacity reaches 1 million pieces per day, and the DIP plug-in processing capacity is 200,000 pieces per day, which can provide you with high-quality electronic processing services.

Related Keywords