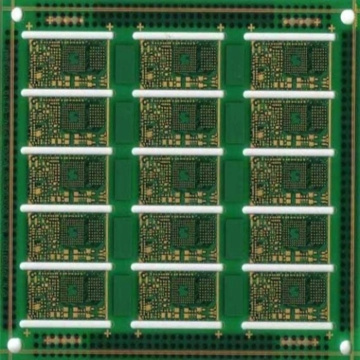

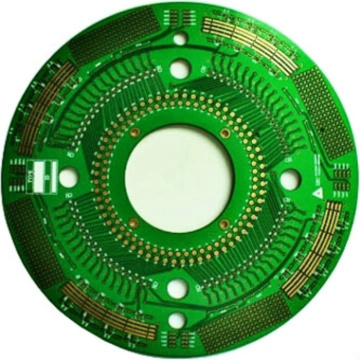

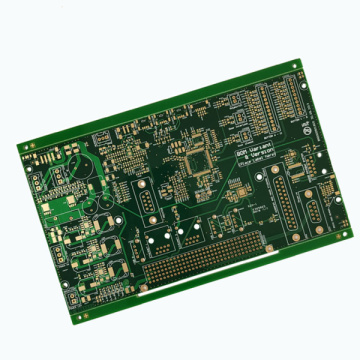

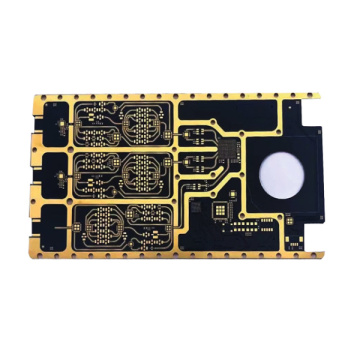

Custom Multilayer Printed Circuit Board

-

$0.80≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow do you make custom circuit boards?

Although there are many ways to make and process PCB circuit boards, the traditional rapid board-making methods can be divided into two categories: physical methods and chemical methods:

Physical method: by using various knives and electric tools, manually carve out the unnecessary copper on the buile-up circuit board.

Chemical method: By covering the protective layer on the blank copper clad board, the unnecessary copper is etched away in the corrosive solution, which is the method used by most developers at present. There are many ways to cover the protective layer, mainly including the most traditional manual lacquer method, custom-made self-adhesive method, film photosensitive method, and the thermal transfer printing method of PCB board which has only been developed in recent years.

Hand-drawing paint: Use a brush or a hard pen to manually draw the shape of the circuit on the blank copper clad laminate. After drying it, it can be put into the solution and corroded directly.

Adhesive stickers: There are various stickers on the market that are made into strips and discs. Different stickers can be combined on the blank circuit board according to the needs, and they can be corroded after being glued tightly.

Film photosensitive: Print the PCB circuit board diagram on the film through a laser printer, and pre-coat a layer of photosensitive material on the blank mulit-wiring printed boardcopper clad laminate (the coated copper clad laminate is available on the market), and expose, develop, fix and clean in a darkroom environment Then it can be corroded in the solution.

Thermal transfer: Print the High frequency board directly on the blank circuit board through a thermal transfer printer, and then put it in the corrosive liquid to corrode.

And the two methods of Quick-turn PCB fabrication also have their own advantages and disadvantages:

Physical method: This method is laborious and has low accuracy. Only relatively simple lines can be used. The main disadvantages are labor-consuming and time-consuming, the accuracy is not easy to control, and there is unrecoverability, and it has high requirements for operation. At present, few people have adopted it.

Chemical method: The process is relatively complicated, but the precision is controllable. It is currently the most widely used rapid plate-making method, but there are still many problems.

A. Printing accuracy depends on the accuracy of the printer cartridge used. Printers with poor performance print uneven lines, which can easily cause disconnection and adhesion during the corrosion process.

B. The exposure and development time of the photosensitive plate is not easy to control, and the best exposure time of each batch of plates will be different, which requires repeated trials to master.

C. The control of the corrosion process is difficult: it is impossible for a monolithic corrosion board to be equipped with the professional control equipment used by the circuit board factory for mass production, and the temperature, concentration, and pH of the corrosion solution will have a greater impact on the corrosion quality. To do a good job of a circuit board, you must have many experience accumulation. Otherwise, the material scrap will be very serious.

D. The photosensitive plate has high environmental requirements and must be stored in full darkness and low temperature conditions, and the exposure process must also be carried out under darkroom conditions.

E. Silver salts (photosensitive materials) and copper salts (corrosion products) are both toxic. Care must be taken during the corrosion process. It is difficult to clean people or clothing when they are stained. Moreover, due to environmental reasons, it is troublesome to dispose of the waste liquid after corrosion.

F. The etched finished board must be worked by hand, and it is difficult to control the accuracy of manual punching.

To sum up, the traditional physical method of plate-making is laborious and time-consuming and has low precision. Although the precision of the chemical rapid plate-making method is controllable, the process is complicated and not environmentally friendly. Regardless of whether it is a physical method or a chemical method, both require high operating skills, so neither can be regarded as a good method that can help engineers achieve Quick-turn PCB Prototypes.

Related Keywords