Special Offer Audio Mixer F4 Usb PCB

-

$9.90≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

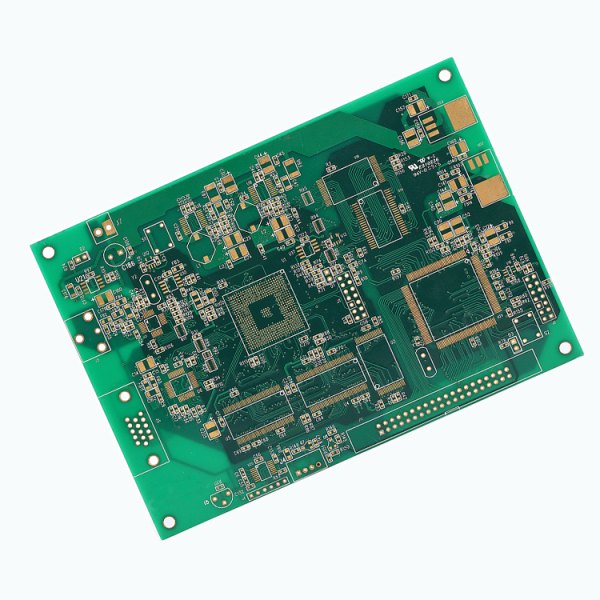

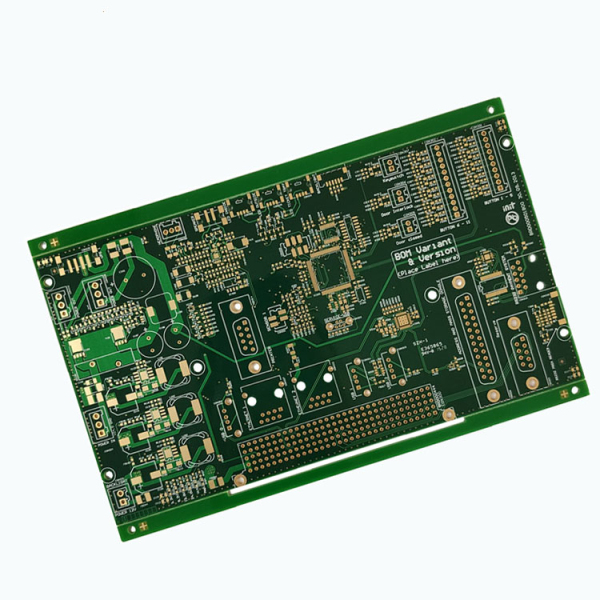

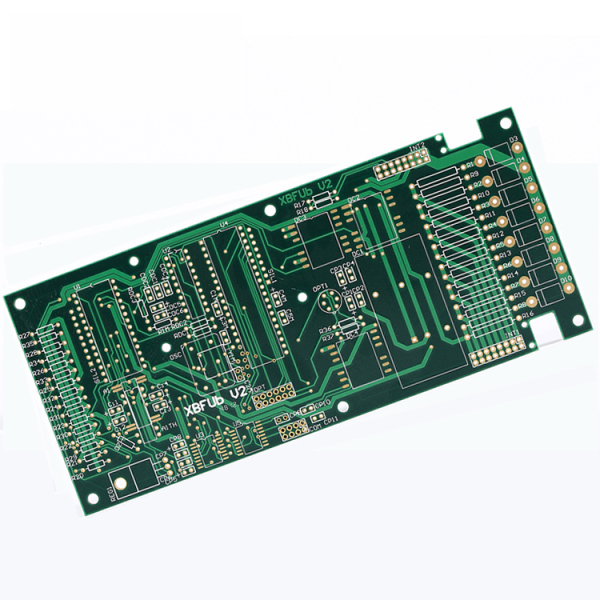

What is HDI technology?

HDI is the abbreviation of High Density Interconnector, which is a (technology) of custom pcb fabrication.

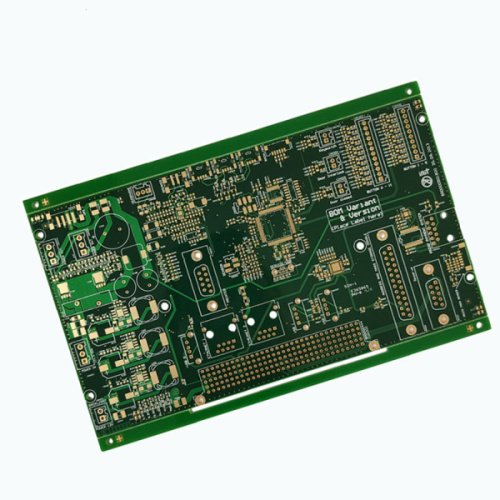

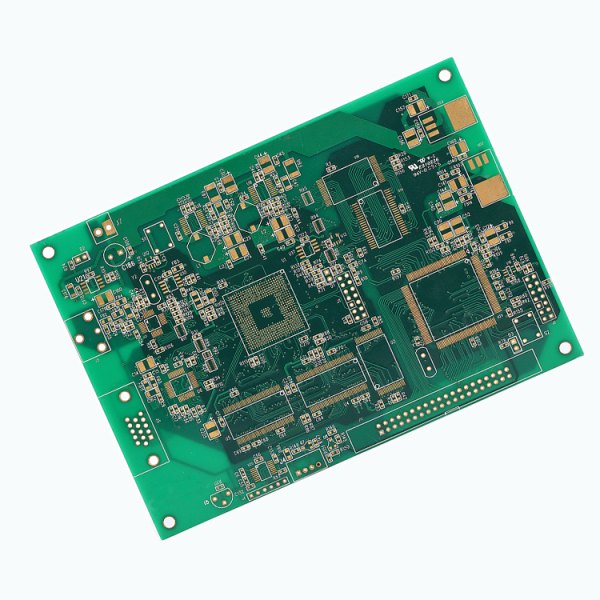

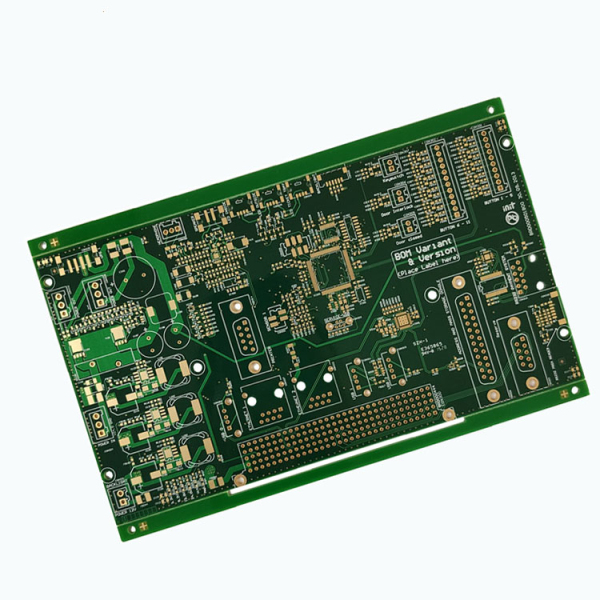

HDI PCB

HDI PCB

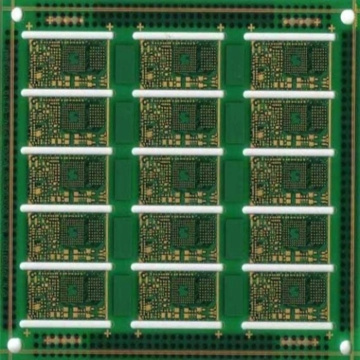

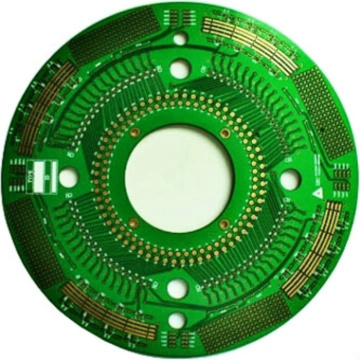

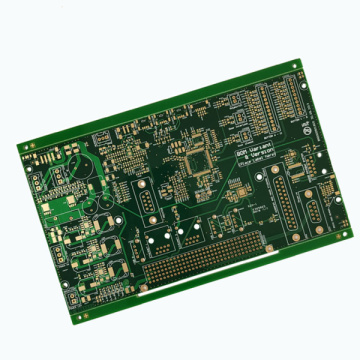

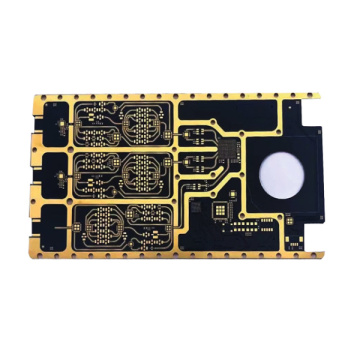

A circuit board with a relatively high line distribution density using micro-blind buried via technology. HDI is a compact product designed for small-capacity users.

HDI PCBs are generally manufactured by layer-by-layer method. The more layers, the higher the technical level of the board. Ordinary HDI PCB is basically one-time build-up. High-end HDI uses two-time or more build-up technology. At the same time, it uses advanced PCB technologies such as stacking holes, electroplating and filling holes, and laser direct drilling.

When the density of the PCB increases beyond the eight-layer board, it is manufactured with HDI, and its cost will be lower than that of the traditional and complex pressing process. HDI PCB is conducive to the use of advanced packaging technology, and its electrical performance and signal accuracy are higher than traditional PCBs. In addition, HDI PCB has better improvements to radio frequency interference, electromagnetic wave interference, electrostatic discharge, and heat conduction.

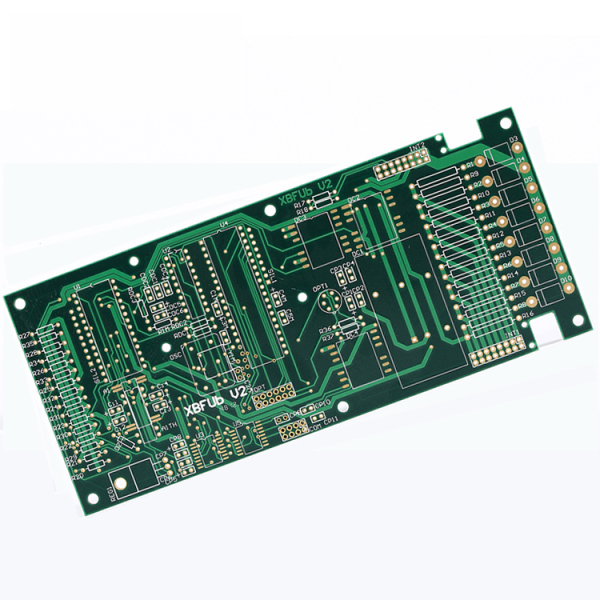

The difference between HDI board and ordinary PCB

Ordinary PCB board is mainly FR-4, which is laminated with epoxy resin and electronic grade glass cloth. Generally, traditional HDI uses backed copper foil on the outer side. Because laser drilling cannot penetrate the glass cloth, glass fiber-free backed copper foil is generally used. However, the current high-energy laser drilling machine can penetrate 1180 glass cloth. . This is no different from ordinary materials.

Related Keywords

Related Keywords