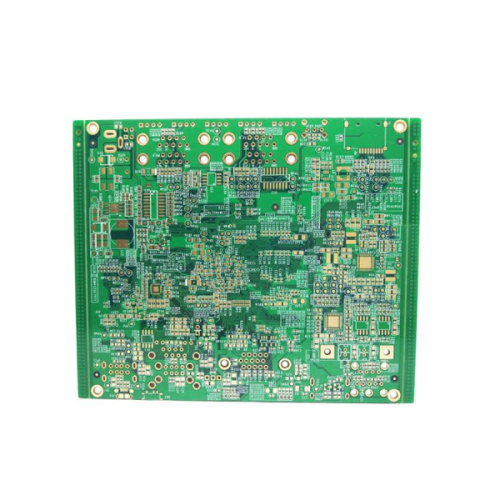

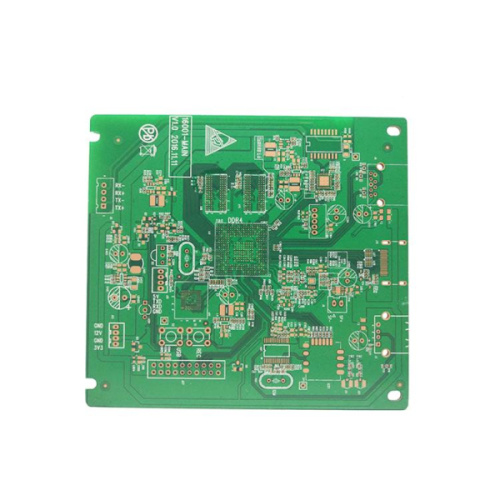

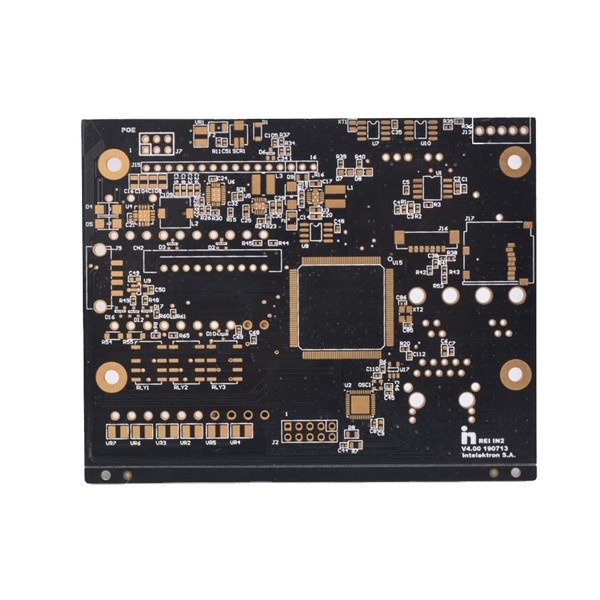

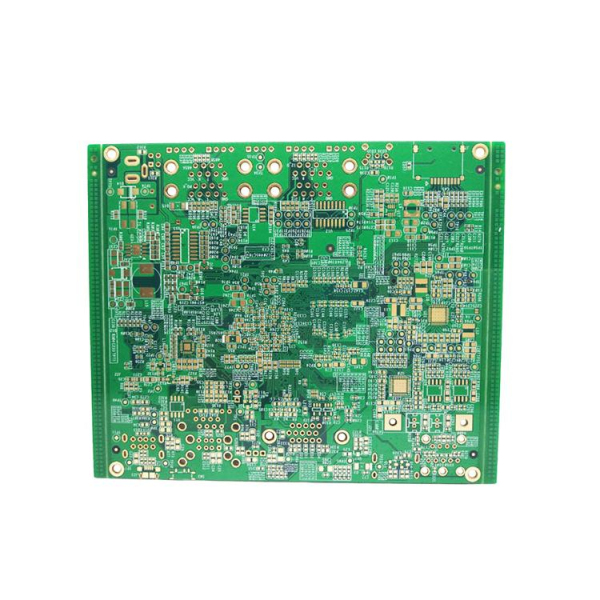

Turnkey Service PCB Assembly SMT/DIP/Through Hole PCBA

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhy is SMT better than through-hole?

Although selecting electrical components for a new PCB can be a tedious task, it is undeniable that it is very important. Designers need to view dozens or even hundreds of variants of parts and check current inventory, future availability and replacement parts. All these choices and considerations are very important, but before choosing components, we need to consider a more basic question: surface mount technology (SMT) or through-hole? Many people think that through-hole devices are old-fashioned, while SMT is a modern style. Although this is true for many applications, through-hole technology still has some clear advantages in some cases. Through-Hole Assembly performs well in circuit boards that withstand high mechanical or thermal stress and have high power requirements. On the other hand, SMT is more suitable for small size.

If you open a random consumer electronic device today, you may not find a lot of Through-Hole Assembly inside. This does not mean that they no longer have a place in the PCB world. It's just that most circuits today don't need their unique advantages. Through-hole devices are also excellent in applications that have strict physical requirements. These applications also have high requirements for heat or power, and can be used for prototyping. However, they are not very useful on small boards that require cheap pcb manufacturing.

Advantages and disadvantages of SMT equipment

SMT devices are very small, faster to place, and can be mounted on both sides of the PCB, so that the manufacturing cost of the SMT board is greatly reduced. The assembly process is not always smooth, because Surface-Mount (SMT) & BGA Assembly may encounter many problems during the manufacturing process.

If you need to manufacture cheap, small and lightweight PCBs, SMT components may be the right choice. They are much smaller than through-hole devices, so they are much lighter. Tiny components mean dense placement on the PCB, and many electronic products today focus on size, so this advantage is hard to beat. The physical form of SMT components also facilitates faster placement during assembly, thereby reducing costs throughout the product's life cycle.

Despite its obvious advantages, SMT manufacturing still faces a series of unique challenges. Although components can be placed faster, the machinery required by PCBA Manufacturing is very expensive. Such a high capital investment in the assembly process means that SMT components can increase the cost of small-volume prototype boards. Due to the increased complexity of mounting, surface-mounted components require higher precision wiring blind via hole PCBs and buried PCBs instead of through-hole PCBs during the manufacturing process. In the design process, accuracy is also important, because violating the contract manufacturer (CM) DFM pad layout guidelines may cause more and more problems, such as logic deletion, which may greatly reduce the yield during the production process.

When should I use surface mount technology (SMT) and through holes?

Although SMT is a newer, more compact component packaging style, and through holes are more suitable for larger circuit boards, both mounting methods will not disappear soon. Each option has unique advantages that can help you determine the best design for you. If you are designing military-grade PCBs or delving into critical system design involving demanding physical and thermal requirements, you may need to use through-hole components. If you want to make the next small consumer electronic device where every detail is critical, then SMT equipment may be for you. No matter which style you decide to adopt, Beat Automation will be ready to bring your PCB to life.

Related Keywords