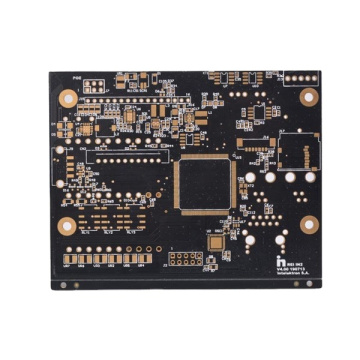

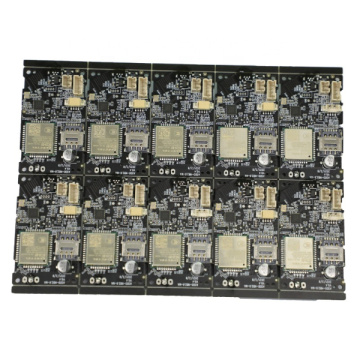

Fast Turnkey Customize Electronic PCBA Service PCB Assembly

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is EMS PCB?

With the development of electronic technology, the division of labor in society has become more detailed. For cheap custom pcb fabrication and High Quality Prototype PCB Fabrication. PCB manufacturers and PCBA assembly plants have undertaken more work for customers. Engaged in electronic processing and manufacturing services. This electronic processing and manufacturing service (EMS) is used for company, testing, manufacturing, distribution, and original equipment manufacturers (OEM manufacturers) of Electronic Components and components that provide return/repair service periods. This concept is also known as electronic product contract manufacturing (ECM).

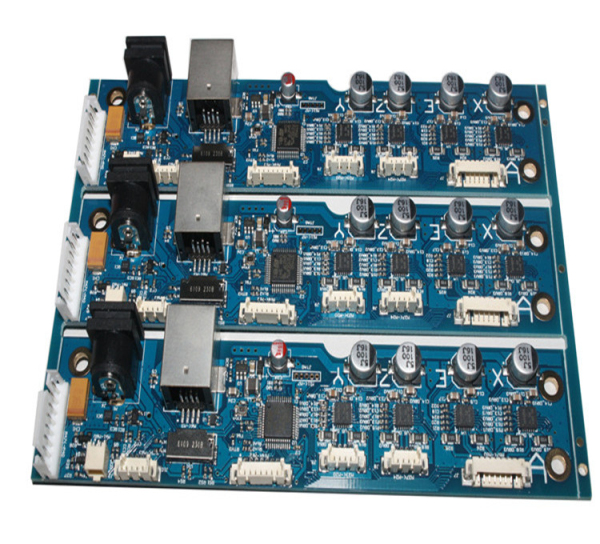

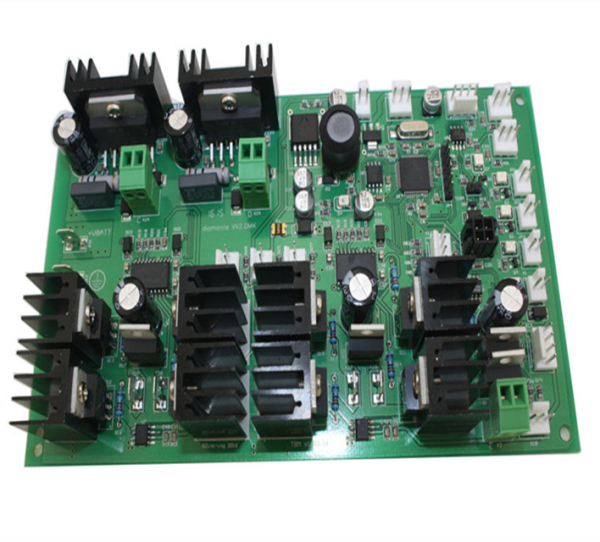

The EMS industry emerged in the late 1970s. At that time, most electronic manufacturing and large-scale products were mostly assembled by the company. The business model EMS industry is specialized in large-scale economic production, raw material procurement and centralized resources, professional solutions for industrial design, and creation of value-added services such as warranty and repair. This will free up customers with huge inventories. Therefore, they can respond faster and more effectively to the sudden peak of demand. Surface-Mount (SMT) & BGA Assembly and Printed Circuit Board (PCB) realize the PCB assembly of electronic products. In the early 1990s, OEM manufacturers quickly installed SMT production lines. By the mid-1990s, the advantages of the EMS concept were noticeable and OEMs began to outsource printed circuit board assembly (PCBA) on a large scale. By the end of the 1990s and the beginning of the 21st century, many OEMs sold their assembly plants to actively compete for market share with EMS. The wave of integration followed, as more cash flushing companies can quickly buy up existing plants and small EMS companies.

DIP plug-in processing refers to the plug-in processing of electronic components that cannot be mounted, and pass the Wave Solder for PCBA soldering, cutting foot quality inspection and other processes. So far, most of the PCBA processing has been completed. Then it needs to be tested and the program is burned. Complete the entire processing process.

Related Keywords