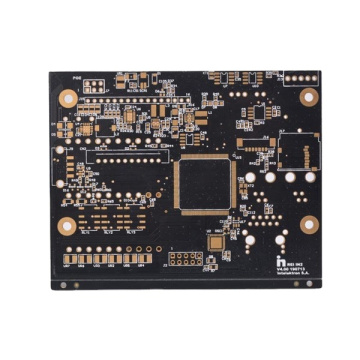

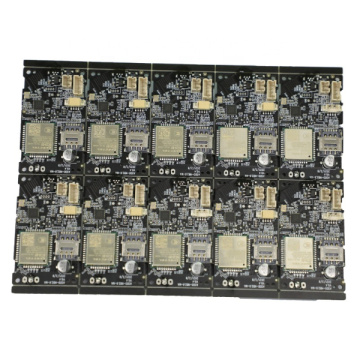

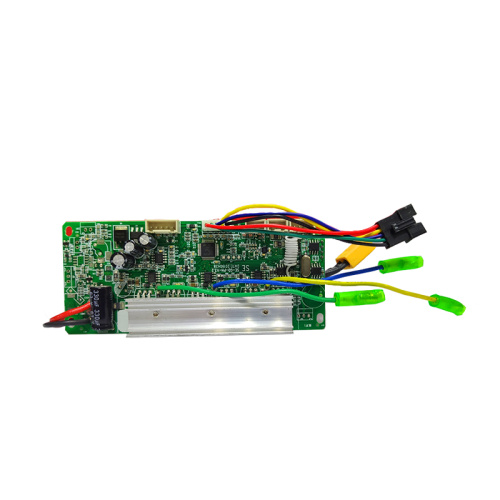

Electronic Pcba Balance Electric Scooter Circuit Board

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat are the 3 steps in the circuit board assembly process?

Printed circuit boards are usually made of fiberglass, copper traces and other conductive materials, which are held together by epoxy. The green color of the circuit board comes from the solder mask, which helps to isolate the entire circuit board and helps prevent conductive elements from interfering with each other.

The following are the four main steps of PCBA Manufacturing process:

Application of solder paste: similar to the T-shirt shield, the solder paste template uses a thin stainless steel template to apply solder paste on the Electronic Components, and the component will be mounted on the printed circuit board. When using solder, a chemical called flux is used to help melt the solder paste and adhere it to the surface of the circuit board.

Picking and placing components: After applying solder paste, the next step in the circuit board assembly process is the pick and place machine. This is where the surface mount components like Electronic connectors,Electronic Resistor and Capacitor, are placed on the printed circuit board. This process was previously done manually by the circuit board assembler, who would use a pair of tweezers to pick and place the components. However, with the advent of robotics, this step has been automated to achieve greater consistency and accuracy.

Soldering: After installing all the components, put the printed circuit board on the conveyor belt and move the conveyor belt to the reflow oven. While inside the oven, the circuit board is heated to melt the solder paste and permanently bond the components to the circuit board itself. In the case where the circuit board includes components other than SMD, it may be necessary to insert through-hole components. However, in these cases, more professional welding methods are required.

Testing and quality control: In some cases, the movement of the printed circuit board during the reflow process will cause the components to be misplaced, resulting in poor connection, no connection at all, or incorrect connection of components. This is why it is important to check and perform some tests to ensure the functionality of the circuit board. Even if all the above steps are carefully completed, the circuit board may still fail the functional test. The failed printed circuit board can either be scrapped or recycled, and the process will restart until the final result is a fully functional printed circuit board.

Related Keywords