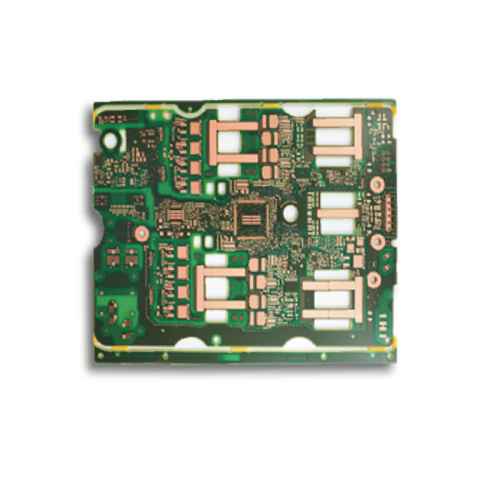

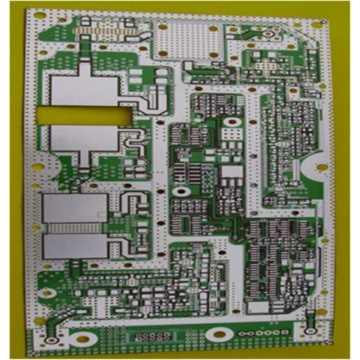

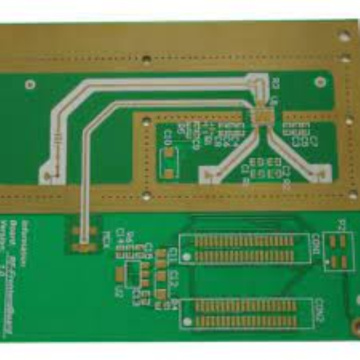

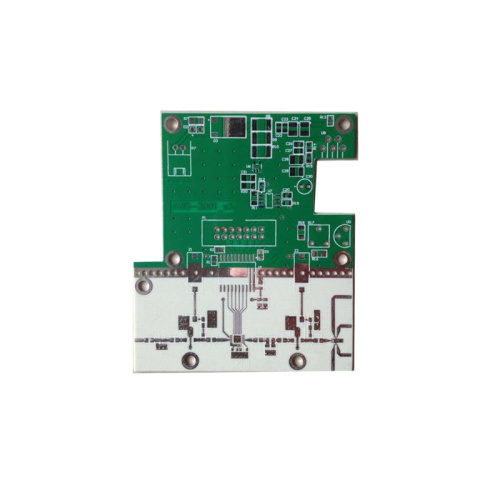

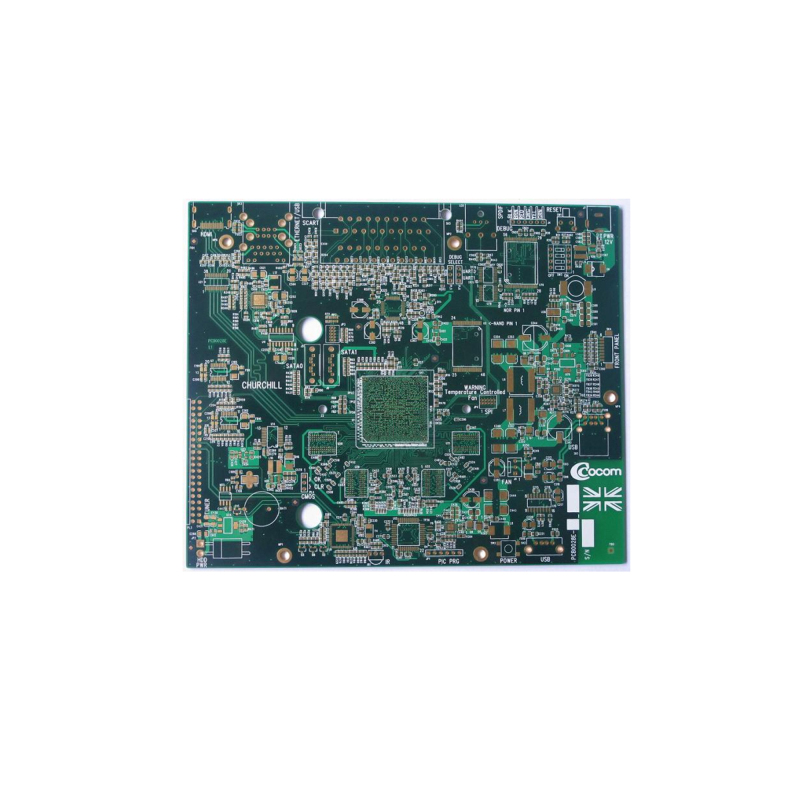

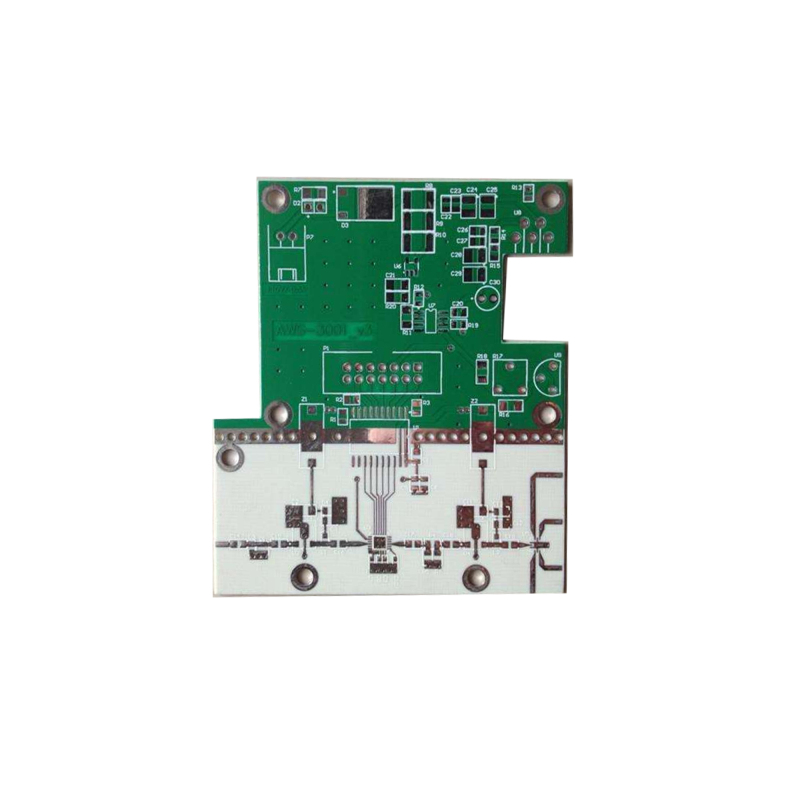

Microwave radio frequency board

-

$0.22≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Land, Air, Express, Ocean

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,EXW |

| Transportation: | Land,Air,Express,Ocean |

| Port: | shenzhen |

What is a microwave PCB?

All RF microwave PCBs that work above 100 MHz are called RF PCBs, and RF microwave PCBs work above 2 GHz. Compared with traditional PCB, the development process involved in RF microwave PCB is different. RF microwave PCBs are more sensitive to various parameters, and these parameters have no effect on ordinary PCBs. Therefore, development is also carried out in a controlled environment with the required expertise.

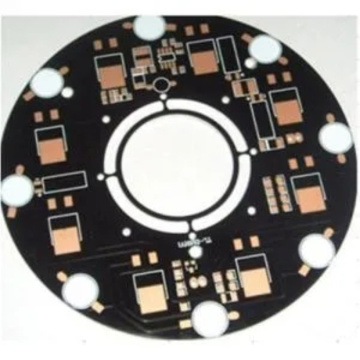

RF microwave PCB applications

RF microwave PCB is used in various products based on wireless technology. If you are developing robots, smart phones, security applications or sensors, you need to choose the perfect RF microwave PCB for your products.

With the advancement of technology, new designs and products are entering the market every day. These advancements have brought about major changes in electronic products. For product developers, it is very interesting to find a suitable PCB for his product to ensure smooth work and long life.

Finding the perfect RF microwave PCB can be stressful for your project, especially when choosing the right PCB material. For the project developer, it is very interesting that his PCB may be a high-level material with appropriate functions and should be delivered in time.

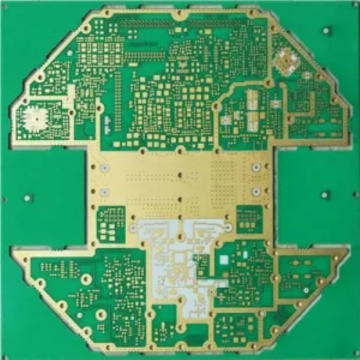

When selecting the perfect material for PCB materials with parameters such as RF, microwave energy level, operating frequency, operating temperature range, current and voltage requirements are very important.

When you start manufacturing PCB, please make sure you have selected the specifications that suit your PCB. The traditional high-frequency RF microwave frequency is a single-layer PCB built on a dielectric. However, with the development of Microwave radio frequency board design, many technologies have emerged in the past few decades.

Why do you need to focus on choosing the right manufacturer?

Ordering PCB manufacturing from high-tech equipment is more advantageous than manufacturing it in low-cost manufacturing plants that use low-grade materials.

RF PCB is very sensitive to factors such as noise, impedance, electromagnetic and ESds. High Quality Prototype PCB Fabrication focuses on eliminating any influencing factors in the manufacturing process. Poor quality RF microwave PCBs are not expected to last long, which is why choosing a perfect RF PCB manufacturer can change your product experience.

Today, most modern RF PCB manufacturing plants use computer-aided engineering software simulation programs for PCB manufacturing. The biggest advantage of CAD-based RF microwave PCB manufacturing is that it has simulation models of various brands and PCB models with appropriate product specifications.

These parameters are essential for standardizing the production of RF microwave PCBs and ensuring reliability. In addition, these machines also support manual operation, allowing operators to perform manual operations.

Therefore, it is obvious that the manufacture of RF microwave PCB is not as simple as it seems. /p>

Why choose RAYMING for RF microwave PCB manufacturing?

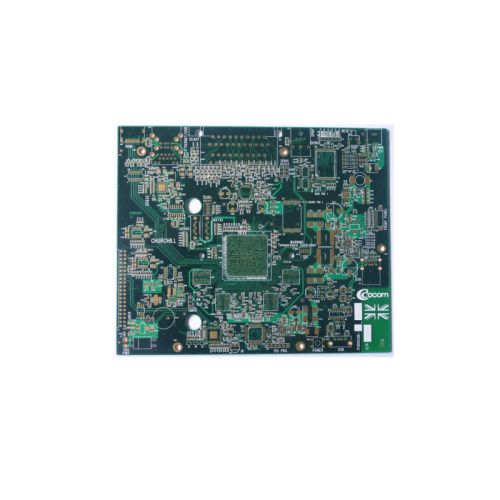

RAYMING has been providing RF PCB manufacturing facilities for many years. RAYMING’s qualified professionals have expertise in PCB manufacturing based on Rogers PCB materials. Fortunately, RAYMING has experienced RF microwave PCB manufacturing for military communication equipment.

RAYMING focuses on Rogers PCB materials and prefers to be used in RF microwave PCB manufacturing. Various Rogers PCB materials enable us to choose the most suitable material according to the requirements.

RAYMING has been committed to providing RF PCB manufacturing facilities for various products around the world. RAYMING’s qualified professionals have expertise in Rogers’ PCB manufacturing. Fortunately, RAYMING has experienced RF microwave PCB manufacturing for military communications equipment.

The materials of military equipment used for PCB assembly are Roger 4003 printed board, Roger 4350 printed board and RT5880. This SMT-based two-tier component contains 250 deployments. The final product is tested on automatic X-ray and optical equipment. The quality assurance department thoroughly inspected each product. These products were delivered after multiple departments were completely satisfied.

Since RAYMING has entered PCB product development and has extensive experience in assisting project developers in various fields, RAYMING has developed a long-term cooperative relationship with its satisfied customers.

One of the main reasons you should consider RAYMING is that its technical support is always available in just a few clicks. RAYMING technical team will provide you with technical support at any time. If you are looking for a manufacturing company that can help you complete the RF PCB manufacturing process and share product development ideas and strategies, you should consider RAYMING.

<strong>Benefits of manufacturing RF PCB through RAYMING

RF microwave PCBs are not as easy to manufacture as ordinary PCBs. Various factors need to be explained and monitored in detail. As an experienced RF microwave PCB manufacturer, RAYMING has developed experience in handling RF projects and has a precise understanding of how to combine these factors. RAYMING is a world-renowned PCB manufacturing brand. High-quality products and customer-satisfying experience have enhanced our image.

It can be difficult to trust the PCB manufacturer with your sensitive products, and we truly understand this. RAYMING not only assists customers in the manufacturing process, but also provides detailed technical support even after PCB manufacturing

We make sure that your PCB manufacturing is not only developed by RAYMING's technical experts, but also that the product's function fully meets the requirements. Before manufacturing, they will analyze the complete design to determine whether there are any possible defects or improvements. Therefore, we will consider customer concerns and develop reliable products.

If the design lacks any specifications or required features, our team is responsible for discussing with customers to provide alternatives. In addition, customers can stay away from the hustle and bustle of testing, because our testing team will perform various tests on your customized RF Microwave PCB and ensure that it can achieve its purpose.

Even slight negligence can cause serious danger in RF microwave PCB design. In addition, it reduces work efficiency, which is where RAYMING has obvious advantages compared with other manufacturers. We are committed to the PCB manufacturing process. After the task is completed, many departments are completely satisfied and the product functions smoothly.

Related Keywords