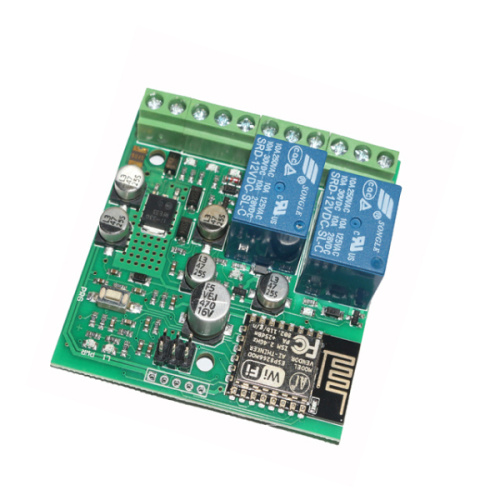

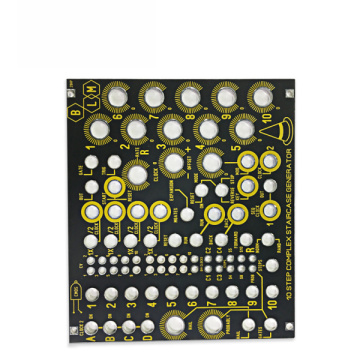

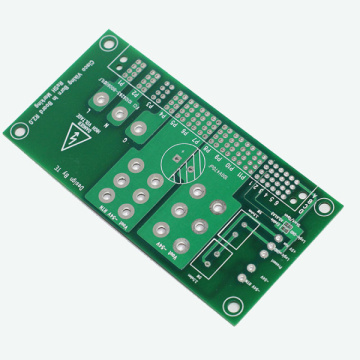

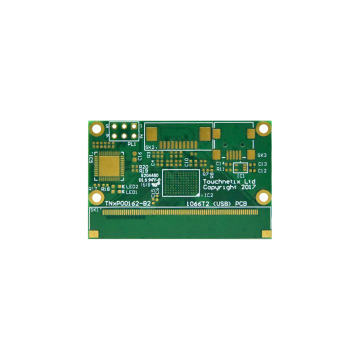

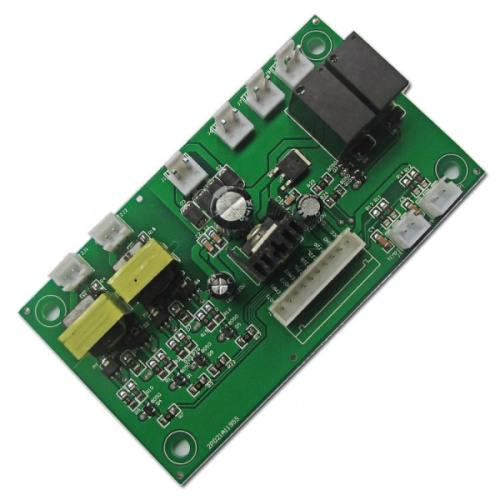

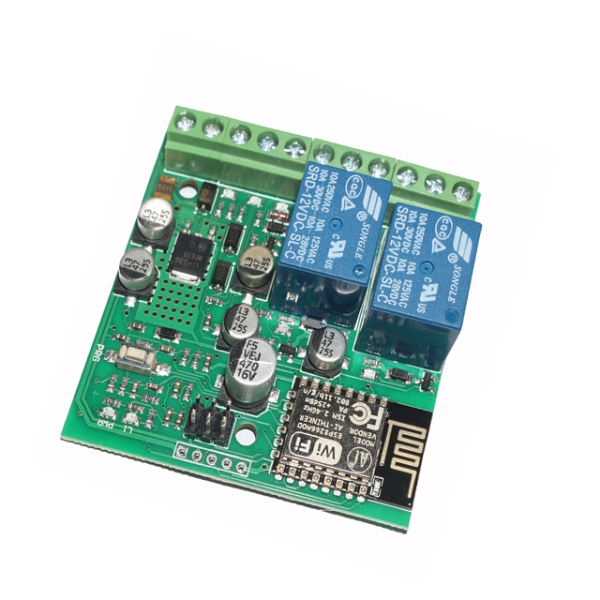

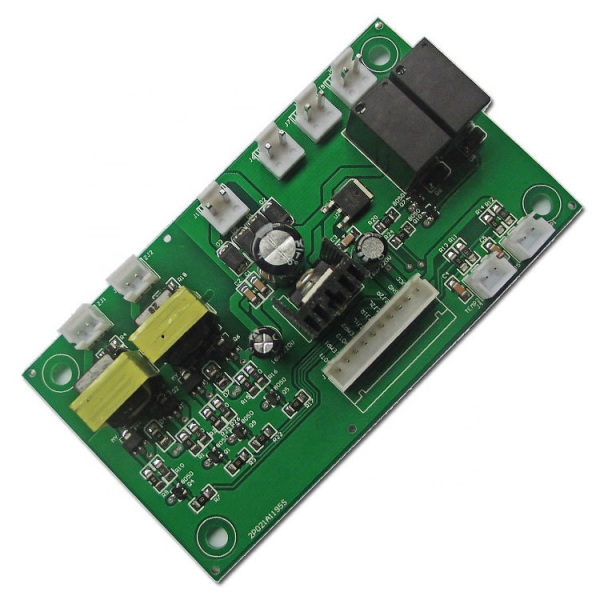

High Quality Power Control PCBA Multilayer PCB Assembly

-

$1.02≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow are multilayer PCBs manufactured?

The printed circuit board (PCB) is one of the most important parts of an electronic circuit and contributes to its performance. Of course, as with the operation of the PCB, it is also important to understand the manufacturing process. Since 60% of PCBs used in industrial electronic circuits are multilayered, the manufacturing process of multilayer PCBs has become a topic of concern. The demand for smaller, more powerful High frequency boards and faster devices for Rigid-Flex Boards, and Quick Turn PCB assemblies have driven the demand for multilayer PCBs. Copper is used as the conductor of these PCBs, which contributes to their current-carrying capacity. This article discusses the manufacturing process of multilayer PCBs and provides insights on choosing a copper multilayer PCB manufacturer.

In essence, the manufacturing process followed by copper multilayer PCB manufacturers is very simple. The manufacturing process proceeds as follows:

Choose the material used for the inner core, prepreg and copper (Cu) foil.

The prepreg is made of glass cloth and epoxy resin.

The core laminate is further covered with copper (Cu) foil of a specific weight and thickness.

These laminates are then covered with a photosensitive dry film so that ultraviolet rays are brought into contact with the resist. By using ultraviolet light, the electronic data of the internal circuit is transmitted to the resist.

This is a core laminate manufacturing process, but multilayer PCBs are manufactured through multilayer lamination. Let us discuss the multilayer lamination process in order to have a thorough understanding of the multilayer PCB manufacturing process.

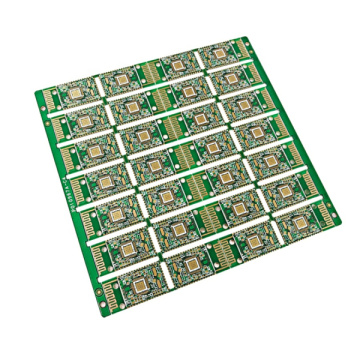

The multilayer lamination of PCB is a sequential process. This means that the base of the layering will be a piece of copper foil, covered with a layer of prepreg. The number of layers of prepreg varies according to operating requirements. In addition, the inner core is deposited on the prepreg layer, and then the inner core is further filled with the prepreg layer covered with copper foil. In this way, a laminate of the multilayer PCB stack is produced. Stack the same laminates together. After adding the final foil, the final laminate is created, called a "book", and each laminate is called a "chapter".

After the book is finished, it is transferred to the hydraulic press. The hydraulic press is heated and exerts a lot of pressure and vacuum on the books. This process is called curing because it inhibits the contact between the laminates and allows the resin prepreg to fuse with the core and foil. The components are then taken out and cooled at room temperature to allow the resin to settle, thereby completing the manufacturing of the copper multilayer PCB.

Although most copper multilayer PCB manufacturers follow the same process, the output is not limited to the process itself. It requires careful attention to details. Therefore, it is essential to cooperate with the appropriate multilayer copper PCB manufacturer.

There are several factors to consider when choosing a multi-layer PC manufacturer for your application. The following points will help you understand it better.

Technical capability: This process requires extensive operator training and specific equipment and technology, which can only be provided by well-known multilayer copper PCB manufacturers.

Experience: Before making a decision, be sure to check the manufacturer’s experience. This can be easily understood from their online profile, or you can confirm it during the discussion stage. You can specifically check the manufacturer's experience in your industry and the type of projects he is engaged in.

Customization options: PCBA Manufacturing Although some electronic devices use standard-size PCBs, many devices also require custom pcb fabrication. Therefore, you need to check whether the selected manufacturer can provide a customized PCB.

Industry-specific certification: If you belong to any key service industry, such as medical, military and defense, aerospace and aviation, etc., this will become the most important factor.

Related Keywords