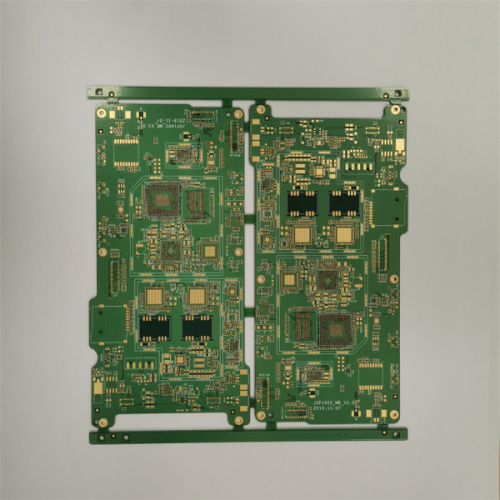

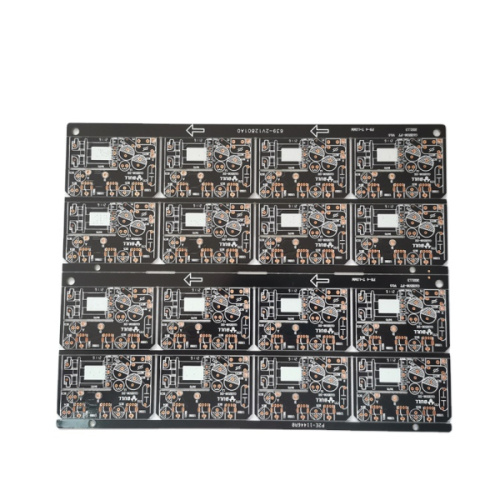

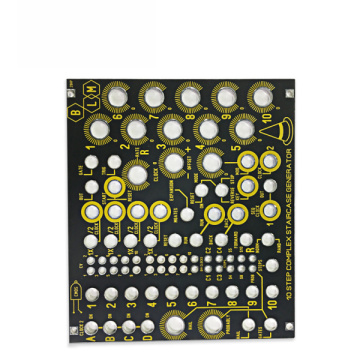

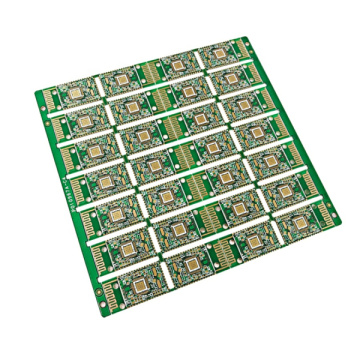

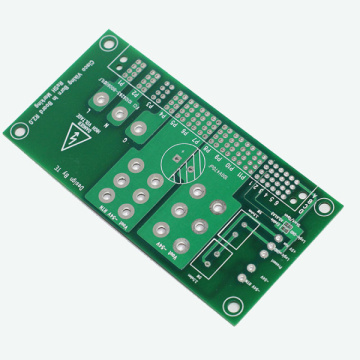

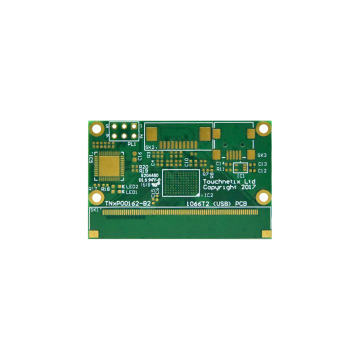

Ro4350B FR4 hybrid Board with High quality

-

$1.02≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is OSP finish in PCB?

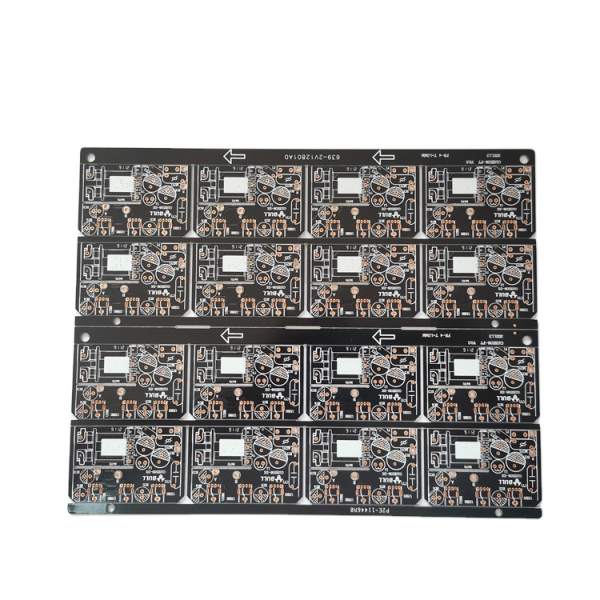

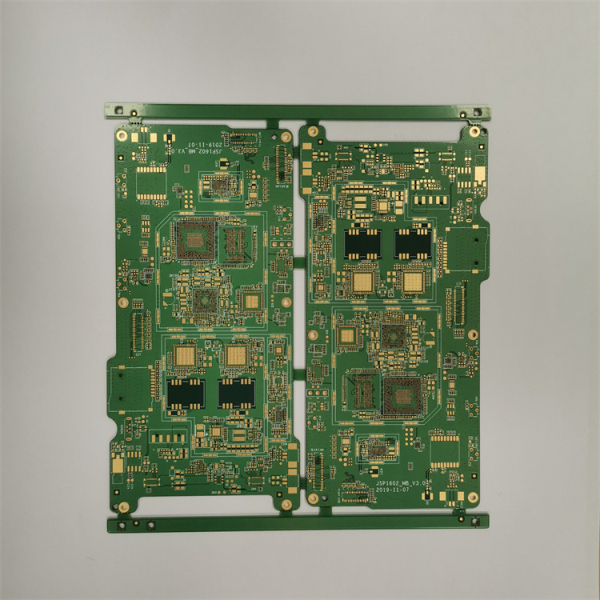

High Quality Prototype PCB Fabrication must perform surface treatment on the PCB. Under the premise of ensuring the quality of PCB, to realize low cost pcb manufacturing, it is also necessary to carry out surface treatment on the PCB. How do we achieve pcb over 99.6% Satisfied rate? Principle: An organic film is formed on the copper surface of the circuit board, which firmly protects the surface of fresh copper, and can also prevent oxidation and pollution at high temperatures. OSP film thickness is generally controlled within 0.2-0.5 microns.

1. Process flow: degreasing → washing → micro-etching → washing → pickling → pure water washing → OSP → pure water washing → drying.

2. OSP material types: rosin (Rosin), active resin (ActiveResin) and azole (Azole). The OSP material used by www.pcbcoming.com is currently the most widely used azole OSP.

Related Keywords