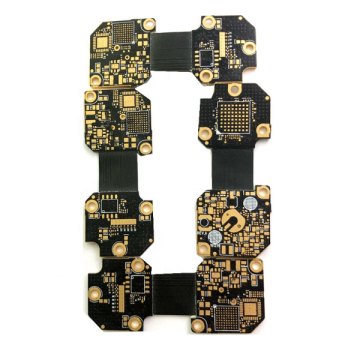

High TG electronic temperature control HDI PCB

-

$32.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is IMS PCB?

IMS is the abbreviation of "InsulatedMetalSubstrate", which is a PCB made of a special prepreg material applied on a metal plate (usually aluminum plate). Its main characteristic is excellent heat dissipation.

The most basic IMS structure usually consists of a circuit layer, an insulating layer and a metal base layer, of which the most important part is the insulating layer. The insulating layer mainly functions as adhesion, insulation and heat conduction. The aluminum base board insulating layer is the largest thermal barrier in the power module structure. It is usually filled with aluminum oxide, aluminum nitride, boron nitride, magnesium oxide or silicon oxide, and its thermal conductivity is usually 8-12 times that of 0-18 Layer FR4 board. . The better the thermal conductivity of the insulating layer, the more conducive to the diffusion of the heat generated during the operation of the Electronic Components, and accelerate the reduction of the operating temperature of the device, thereby providing the power load of the module and extending the service life.

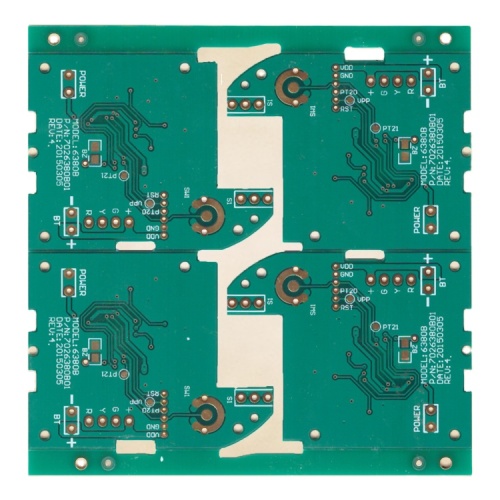

The thermal resistance of an IMS PCB can be designed to be very low. The following picture shows the thermal imaging comparison of the same 35μm copper thickness FR4 PCB and IMS PCB LED under the same load condition:

Related Keywords