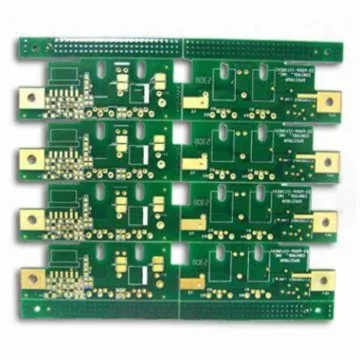

Prototype PCB-Assembly with quick delivery

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow does PCB assembly process work?

Printed circuit board assembly, also known as PCBA , is the process of soldering or PCBA Manufacturing of electronic components to a PCB or printed circuit board.

Be sure to include the board revision and other identifiers, such as the release date, to clearly distinguish the design.

Specify the level of IPC (or other standard) inspection required.

Specify solder alloy requirements, especially if the RoHS standard must be met.

Specify any components or areas of the circuit board that require special attention, such as polarization, moisture sensitivity, and restricted areas.

Ensure any process or readability requirements. Silkscreen includes reference indicators, labels and markings.

Make sure that the package on the PCB layout is accurate for your MPN. List of BOM components.

Including component riveting (before SMT), underfill, material and hardness requirements.

Including washing, cleaning, conformal coating and encapsulation.

Ensure that the image is comprehensive and include any mechanical hardware additions, such as heat sinks and radiation shielding elements.

Clearly specify any additional processes, such as drying or functional testing.

Including sub-board instructions.

Following the practices outlined in the list above will help facilitate the construction of circuit boards while ensuring that they meet your reliability and performance goals. And to ensure that your instructions meet the needs of your CM, you should follow the PCB design and development checklist,

Related Keywords