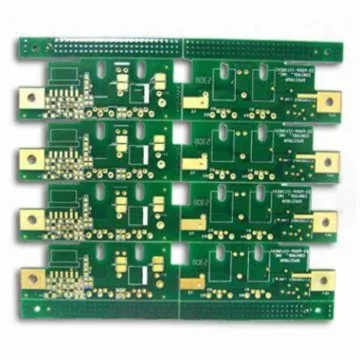

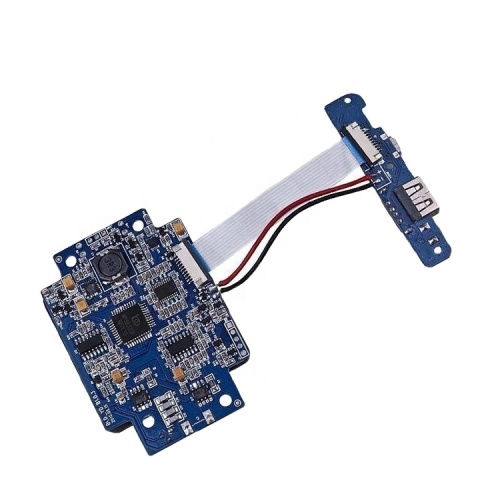

High quality pcba custom rigidity flex pcb

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow do you make a rigid flex PCB?

The material selected for the Flex High Quality PCB Fabrication board directly affects the production and performance of the board.

For copper clad material, we use Nippon Steel's non-adhesive polyimide (PI) flexible substrate (SB18-25-18, SB18-50-18, etc.). Polyimide PCB is a very good Flexible, excellent electrical properties and heat-resistant materials, but it has greater moisture absorption and is not resistant to strong alkalis. The reason for choosing a substrate without an adhesive layer is that the adhesive between the dielectric layer and the copper foil is mostly acrylic, polyester, modified epoxy resin and other materials, among which the modified epoxy resin adhesive is flexible Polyester adhesives are flexible, but have poor heat resistance. Acrylic adhesives are satisfactory in terms of heat resistance, dielectric properties, and flexibility, but their glass transition The low temperature (Tg) (around 40°C) and the extremely poor alkali resistance make it difficult to process and weld.

Due to the low Tg of the acrylic adhesive sheet, the large amount of contamination generated during the drilling process is not easy to remove, which affects the quality of the metallized holes and various unsatisfactory aspects of other adhesive materials. Therefore, the layer of the multi-layer flexible board We use polyimide material for the bonding layer, such as SPB50A, SPB35A of Nippon Steel, etc., because it cooperates with the PI base material, and the CTE (Coefficient of Thermal Expansion) between them is consistent, which overcomes the dimensional instability in the multilayer flexible circuit. Sexual issues, and other performance can be satisfactory.

There are generally two types of protective materials for the outer pattern. One is a dry film type (covering film), and the other is a polyimide material, which directly connects with the ceramic substrate printed board to be protected after etching without an adhesive. Laminating method, this kind of covering film requires pre-formed before pressing, exposing the part to be welded, so it cannot meet the requirements of tighter assembly. The other is photosensitive and developing type covering dry film, which is pasted by a laminator and passed The photosensitive developing method leaks out the welding part, which solves the problem of assembly fineness. There is also a liquid screen printing type covering material. The commonly used thermosetting polyimide materials, such as Nippon Steel SPI200 and photosensitive developing flexible Special solder resist ink for circuit boards, such as Gao's XV-601T, etc. This type of material can better meet the requirements of fine-pitch, high-density assembly of flexible boards.

Related Keywords