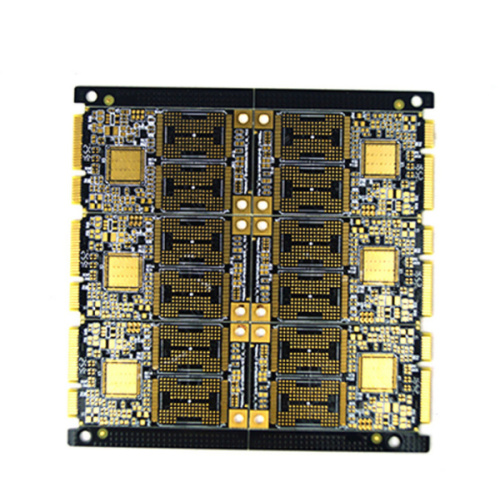

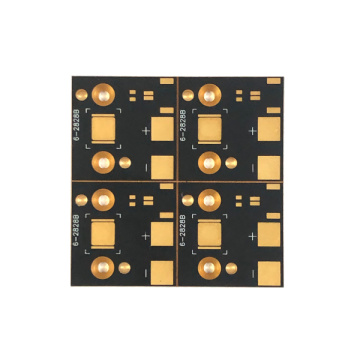

Prototype Metal Core PCB

-

$1.87≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | Paypal,T/T |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Express,Air |

| Port: | shenzhen |

Product Description

Product Description

How does aluminum PCB work?

Printed circuit boards (PCBs) can be made of a variety of metals. These special PCBs are called metal core printed circuit boards (MCPCBS). The choice of metal varies according to the application. Aluminum PCB is one of the popular types of metal MCPCB and can be used in many modern applications. These PCBs have metal base and copper clad laminates. This structure makes the circuit board an excellent electrical insulator and thermal conductor. It also helps the PCB provide high performance.

Aluminum printed circuit boards have the ability to dissipate heat from electronic products. Aluminum PCB is one of the most commonly used types. It has standard FR4 laminate and aluminum core. The circuit board effectively helps dissipate heat with its unique thermal insulation layer. These printed circuit boards are most widely used in applications involving tight tolerances and high power.

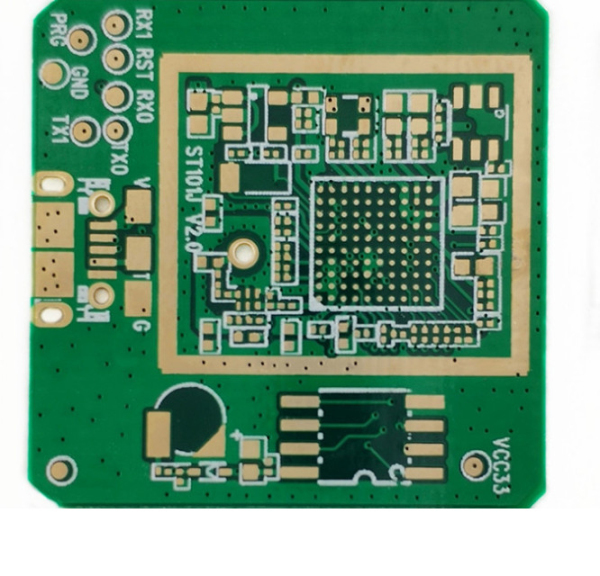

Three layers in aluminum PCB

Compared with other types of PCBs, the design and manufacturing of aluminum PCBs are different. The printed circuit board consists of three main layers.

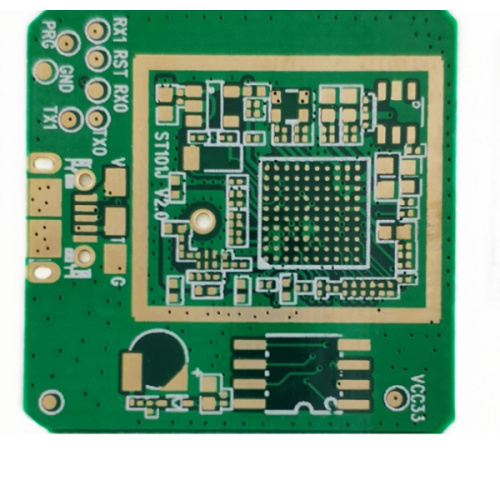

Circuit layer

The circuit layer of the aluminum circuit board is composed of copper foil. These copper foils can be used in weights ranging from 1 to 10 ounces.

heat insulation

The thermal insulation layer of the circuit board is composed of ceramic polymer. The polymer has good heat resistance and viscoelasticity. It is the most important layer and helps protect the circuit board from potential mechanical and thermal stress.

Grassroots

Composed of aluminum alloy matrix. These types of SMT&Through-Hole Assembly are ideal for through-hole technology. Thanks to the presence of aluminum.

In the process of manufacturing an aluminum PCB, a thin dielectric layer is added between the circuit layer and the base layer. The dielectric layer is both electrically insulating and thermally conductive. After adding the dielectric layer, the circuit layer or copper foil is etched. This allows you to obtain the desired pattern. The metal base layer of the circuit board helps to eliminate all heat in the circuit with the help of a thin dielectric layer.

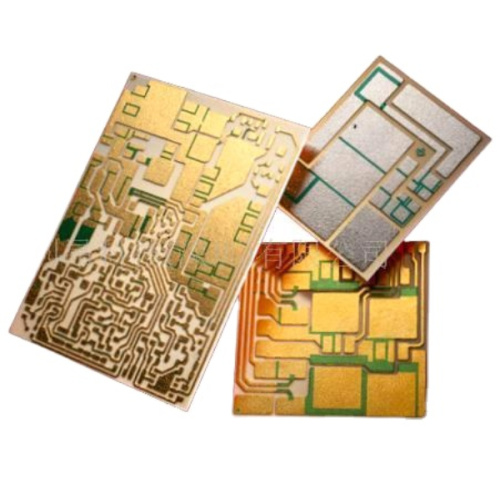

Divided into three main types:

1. Through Hole Aluminum PCB

On through-hole aluminum circuit boards, aluminum is pre-drilled. After that, the dielectric is backfilled into the hole.

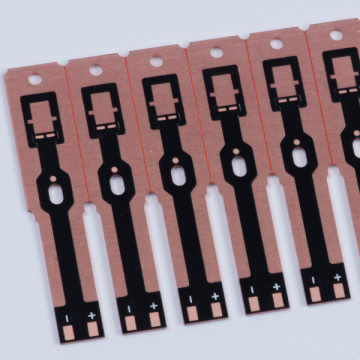

2.Rigid-Flex Board aluminum PCB

In these PCBs, flexible dielectrics are used, which provide a high level of flexibility, thermal conductivity, and electrical insulation. When these dielectrics are used together with aluminum materials, the products formed thereby are highly flexible and can be formed into different shapes. This helps eliminate expensive connectors and fixtures.

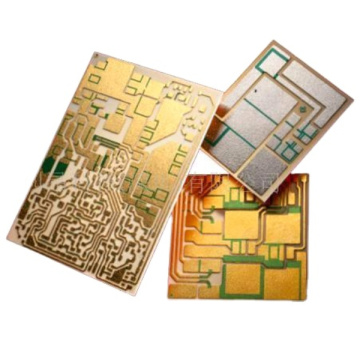

3. Mixed aluminum PCB

These types of aluminum PCBs are commonly used in RF applications and are known to provide better thermal performance when used in standard FR4 PCB products.

The many advantages provided by aluminum sheet make it popular in a variety of applications. Here are some benefits:

1. Lightweight

It is one of the biggest advantages of these PCBs. Aluminum is an extremely light metal. Therefore, it helps increase the strength and elasticity of the PCB.

2. Able to dissipate heat

As long as important components on the circuit board are exposed to high temperatures, they can all be damaged. Therefore, in order to protect them from such damage, it is necessary to use materials that can dissipate heat. Aluminum is a material that can take the generated heat away from important components on the board, thereby protecting them from any potential damage.

3. Lasting

Aluminum is a strong and durable material with high durability. By using aluminum circuit boards, the risk of accidental breakage during handling, manufacturing or daily use can be eliminated. Compared with glass fiber and ceramics base copper-clad laminates, it can provide products with better strength.

4. Environmental protection

Aluminum PCB is easy to assemble and helps to save energy. In addition, the material is recyclable and non-toxic. This makes it environmentally friendly and thus helps protect our planet.

5. Economy

Aluminum can be found in almost any climate, which makes mining and refining easier. This helps reduce costs. Therefore, manufacturing processes involving aluminum are cheaper than other metals.

Related Keywords

Related Keywords