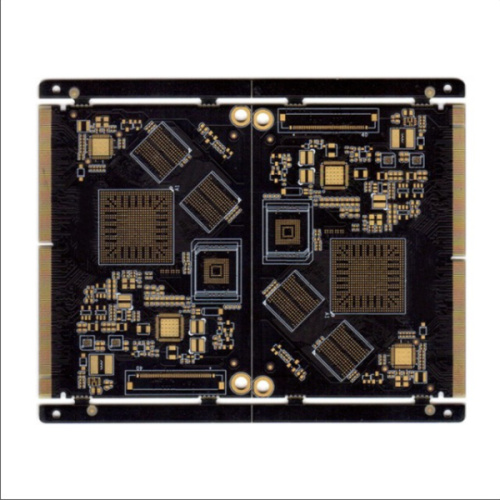

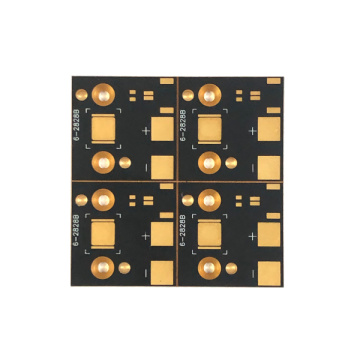

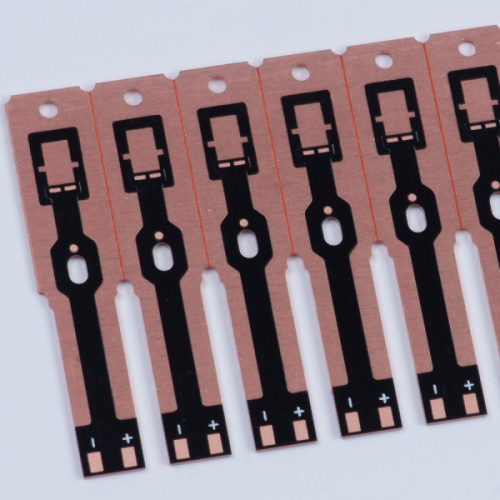

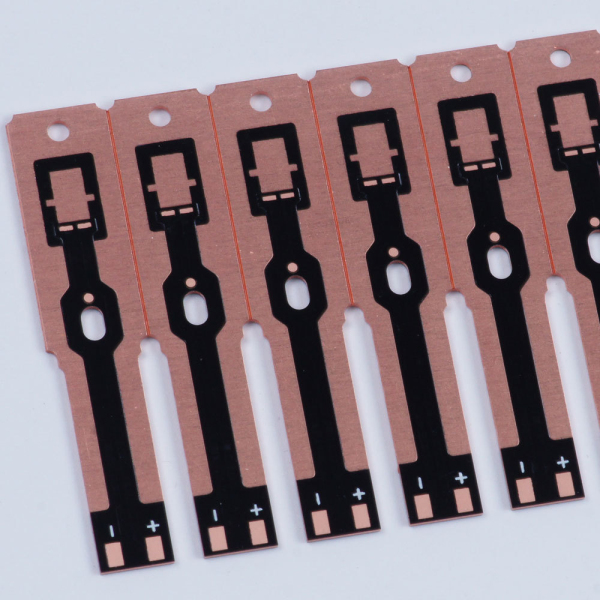

Aluminum LED PCB / MCPCB Metal Core PCB

-

$1.87≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | Paypal,T/T |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Express,Air |

| Port: | shenzhen |

What are the disadvantages of using FR4-based PCB?

FR4 PCB also has shortcomings, how to avoid using FR4 material?

If your application requires any of the following, FR4 material is not the right choice:

1. Excellent heat resistance: If you want to use PCB in a high temperature environment, it is recommended not to use FR4 material. For example, for PCBs in aerospace applications, FR4 material is not the right choice.

2. Lead-free soldering: If your customers need RoHS-compliant PCBs, they must use lead-free soldering. In the lead-free soldering process, the reflow temperature may reach a peak and reach 250 degrees Celsius, and due to its low temperature resistance, FR4 materials cannot withstand it.

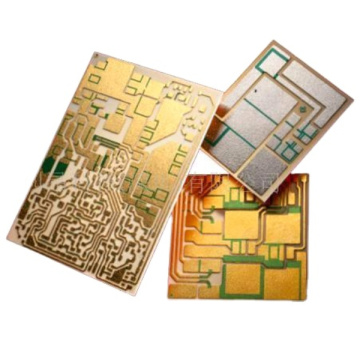

3. High-frequency signal: When the Microwave radio frequency board is exposed to high-frequency signals, the FR4 board cannot maintain a stable impedance. As a result, fluctuations may occur and may affect the integrity of the signal.

Due to their popularity and widespread use, today, it is easy to find FR4 PCB materials with various specifications and functions on the market. Such a wealth of choices can sometimes make choices difficult. In this case, it is important to discuss your requirements with the manufacturer.

1. FR4 is a low-cost material.

2. It has a high dielectric strength, which contributes to its electrical insulation performance.

3. The material has a high strength-to-weight ratio and is light in weight.

4. It is moisture-proof and also has a relative temperature.

5. The material has good electrical loss performance.

6. FR4 does not absorb water, so it is also suitable for various marine PCB applications.

7. The material is yellow to light green, which is very suitable for any application.

All these characteristics make it suitable for various environments.

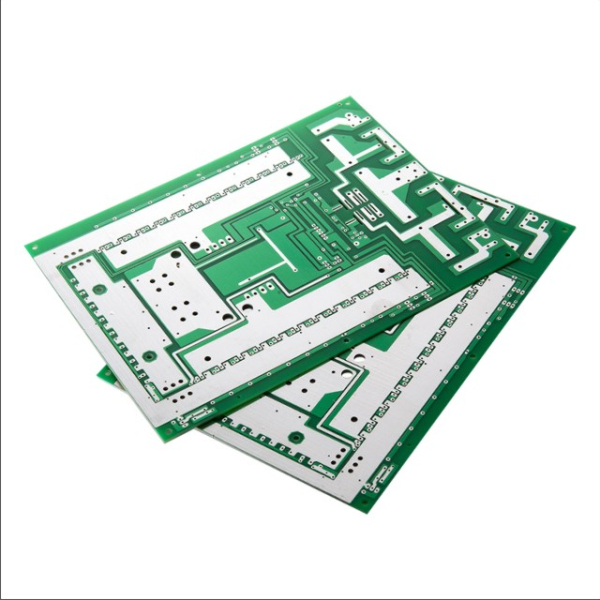

FR4 serves as the foundation of any PCB. The material is laminated with a copper foil layer. Use heat and adhesive for lamination. Copper foil can be used to laminate materials from one or both sides.

Tips for choosing the right FR4 material for your FR4 printed circuit board

It is very important to use the correct thickness of material to build FR4 PCB. Thickness is measured in inches, such as thousands, inches or millimeters. There are several things to consider when choosing FR4 material for your PCB. The following tips will simplify your selection process:

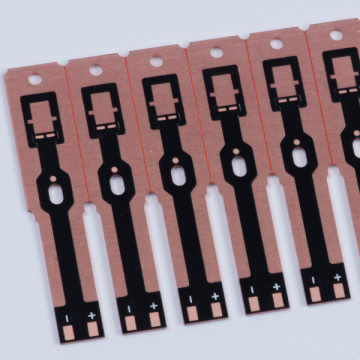

1. Choose thin FR4 materials for building boards with space constraints. The thin material can support various precision PCB assemblies required to build devices, such as Bluetooth accessories, USB connectors, etc. They are also suitable for large projects where engineers want to focus on space-saving design.

2. The thin FR4 material is suitable for applications requiring flexibility. For example, 6 layer Rigid-flex Immersion Gold PCB is ideal for using thin materials for automotive and medical PCBs because these PCBs need to be bent regularly.

3. Avoid choosing thinner materials for PCB designs with grooves, as this will increase the risk of damage or circuit board cracking.

4. The thickness of the material will affect the weight of the printed circuit board and may also affect the compatibility of the components. This means that the thin FR4 material will logically contribute to the manufacture of lightweight circuit boards, thereby producing lightweight electronic products. These lightweight products are attractive and easy to transport.

Related Keywords