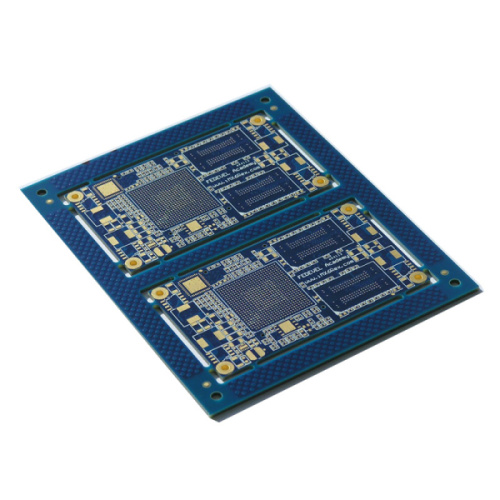

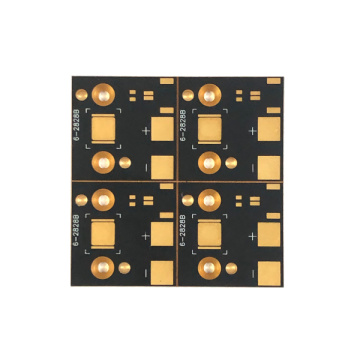

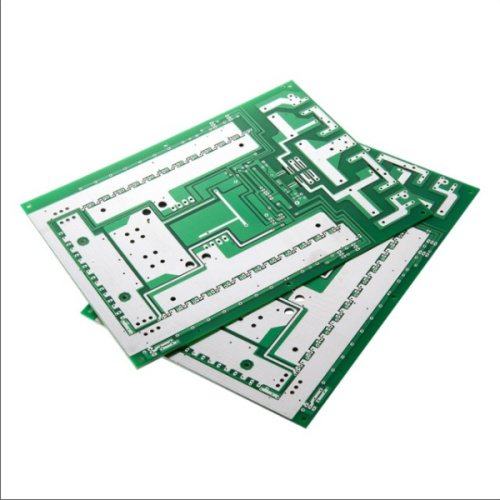

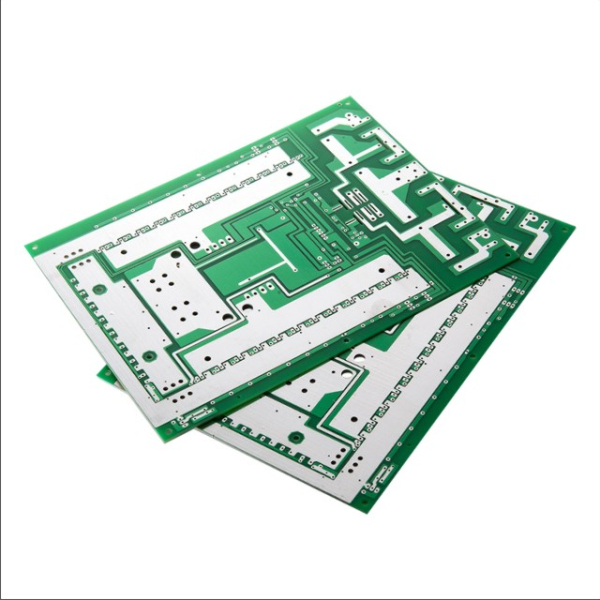

4 layers Aluminum core PCB

-

$1.87≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | Paypal,T/T |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Express,Air |

| Port: | shenzhen |

Product Description

Product Description

What are the advantages of metal core boards?

Metal Core PCBs (also known as MPCBs) are very popular, and due to some of the unique advantages they provide, they are chosen as regular FR4 PCBs. Their advantages, types and applications. Single-layer PCBs are one of the most popular metal core PCB types available for purchase.

The single-sided PCB layer has the following components

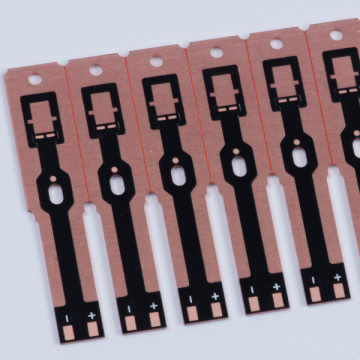

Base metal layer-usually copper alloy or aluminum.

Dielectric layer-this is a non-conductive layer

Copper circuit layer

Solder mask

originality electronics IC

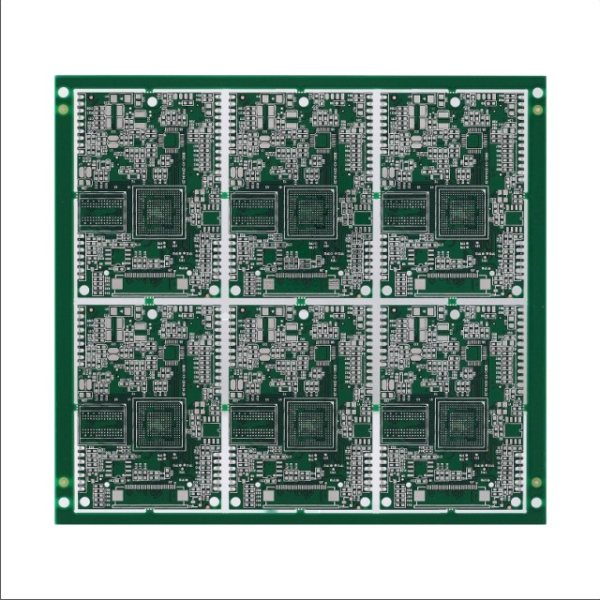

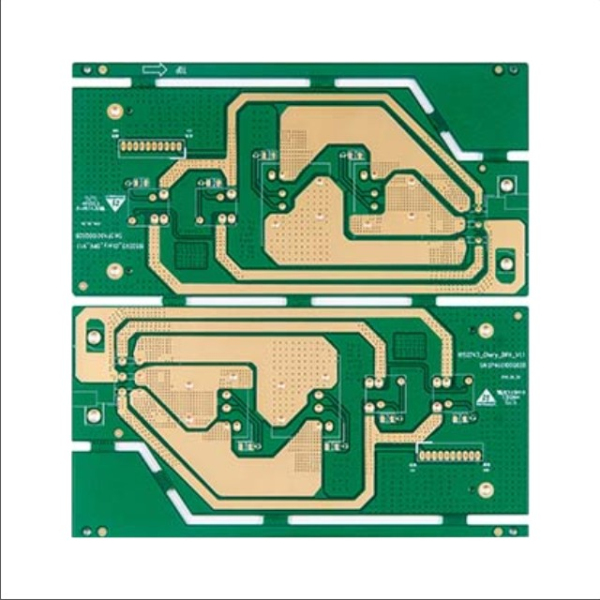

In this circuit, a thin layer of electrically insulating dielectric is laminated between the copper foil and the metal substrate. The copper foil is usually etched in a desired pattern. The base metal layer provides mechanical integrity to the PCB and aids in heat distribution and transfer of heat to the heat sink, ambient air or mounting surface. Aluminum is the most preferred metal for metal core PCBs because aluminum is cheaper than copper alloys. The dielectric provides electrical isolation and helps transfer heat from the component and the foil to the metal plate. In short, the metal layer works with the dielectric to remove heat from the PCB. This is why the single-layer MPCB is used with many wires and chip components as well as Surface-Mount (SMT) &BGA Assembly. Compared with conventional FR4 PCBs, these PCBs provide excellent thermal resistance.

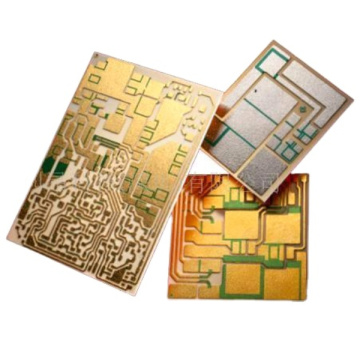

As mentioned earlier, most MPCBs are made of copper or aluminum alloys. Here, we will discuss the benefits of a single-layer metal core PCB made of a layer of copper or aluminum.

Heat transfer and heat dissipation: Generally, single-core base metal PCBs have better heat dissipation and heat transfer characteristics than FR-4 PCBs. Copper has better thermal conductivity than aluminum and can dissipate heat in the air faster. However, aluminum is considered perfect in many applications because aluminum has a lower density than copper, so it will cool faster when it is removed from the heat source. Therefore, aluminum has better heat dissipation properties than copper.

Distortion is not easy to occur: when the aluminum or copper layer is not easy to compare with FR-4 printed circuit board, the distortion caused by heating. This makes them ideal for high switching power applications.

HDI PCB high-density design is easy to implement: single-layer aluminum or copper backed PCBs are used in high-density designs because their thermal conductivity is better than glass fiber PCBs.

Related Keywords

Related Keywords