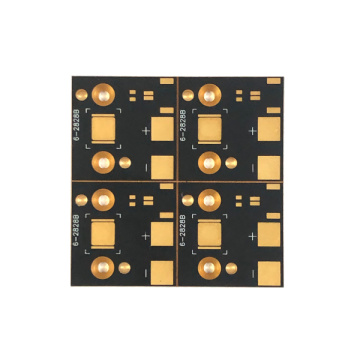

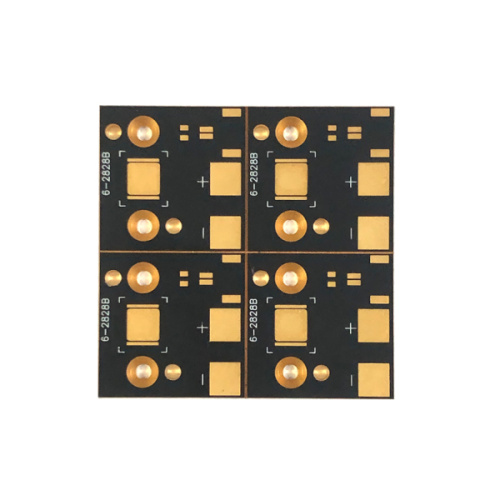

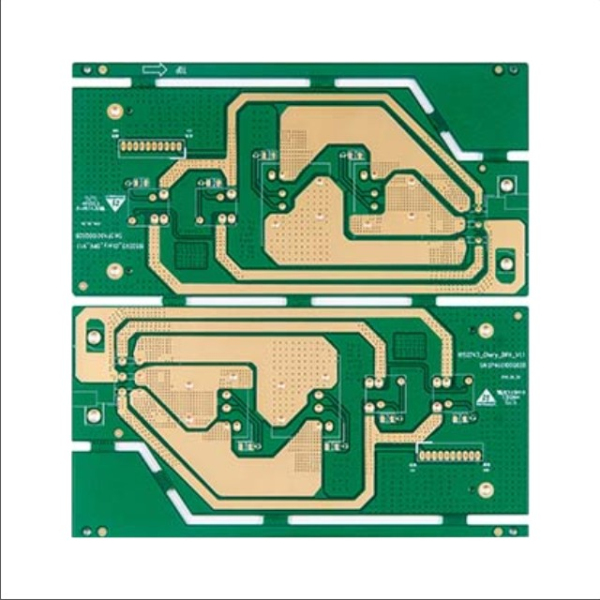

2 Layer Metal Core PCB Copper Based PCB

-

$1.87≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | Paypal,T/T |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Express,Air |

| Port: | shenzhen |

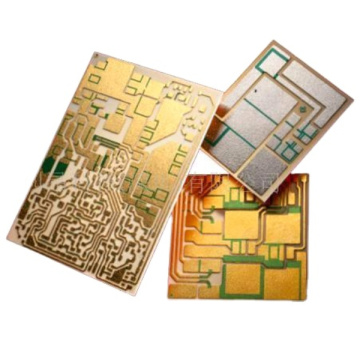

What is copper-based PCB?

Copper substrate is the most expensive PCB among metal substrates. Its thermal conductivity is many times better than Aluminum base board and iron substrate. It is suitable for high frequency board and areas with large changes in high and low temperature, as well as heat dissipation and architectural decoration industries for precision communication equipment.

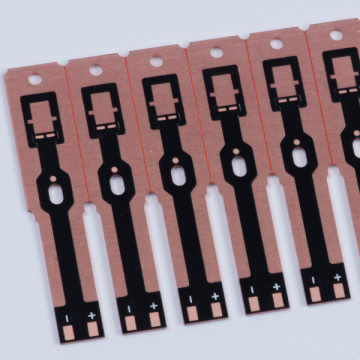

The circuit layer of the copper substrate is required to have a large current-carrying capacity, so thicker copper foil should be used, the thickness is generally 35μm~280μm;

The thermal insulation layer is the core technology of the copper substrate. The core thermal conductivity component is composed of aluminum oxide and silicon powder and epoxy resin filled polymer. It has low thermal resistance (0.15), excellent viscoelasticity, and thermal aging resistance. Ability to withstand mechanical and thermal stress.

The metal base layer is the supporting member of the copper substrate, which requires high thermal conductivity, and is generally a copper plate, which is suitable for conventional machining such as drilling, punching and cutting.

1. Cutting: Cut the raw material of the copper substrate into the size required in the production.

2. Drilling: Positioning and drilling of copper substrate plates will provide help for subsequent processing.

3. Circuit imaging: present the required part of the circuit on the copper substrate sheet.

4. Etching: Keep the required part after the circuit is imaged. The rest does not need to be partially etched away.

5. Screen printing solder mask: prevent non-soldering points from being contaminated with solder, and prevent tin from entering and causing short circuits. The solder mask is particularly important when performing Wave Solder for PCBA, which can effectively protect the circuit from moisture.

6. Silk screen characters: for marking.

7. Surface treatment: protect the surface of the copper substrate.

8. CNC: Perform numerical control operations on the entire board.

9. Withstand voltage test: test whether the circuit is working normally.

10. Packaging and shipping: The copper substrate confirms that the packaging is complete and beautiful, and the quantity is correct.

Related Keywords