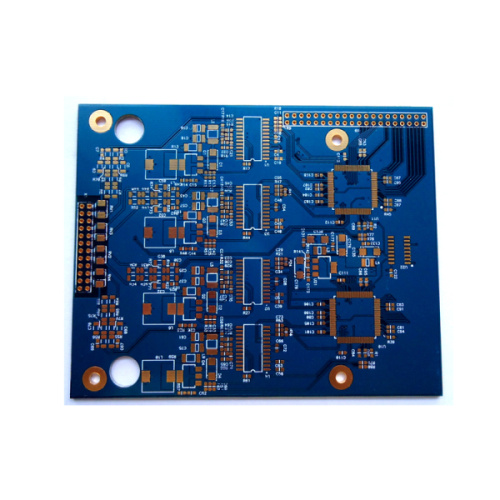

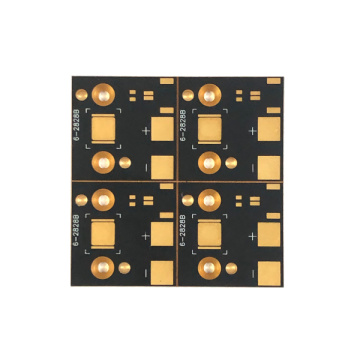

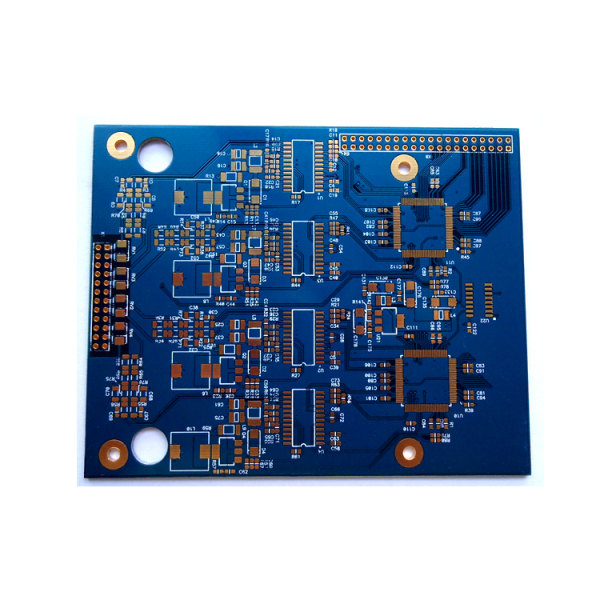

Measuring cardiac pacemakers instrument PCBA assembly

-

$1.87≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

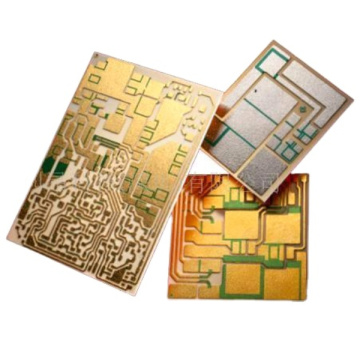

What is a ceramic substrate?

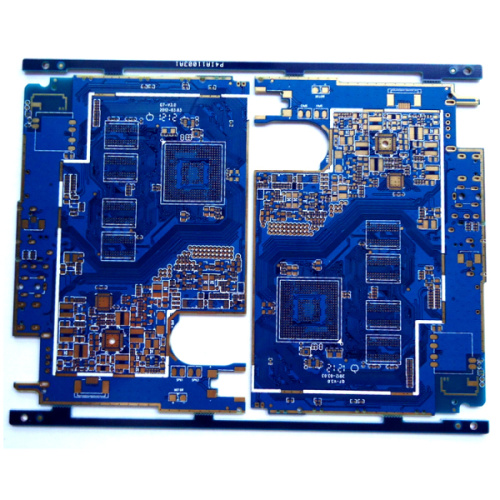

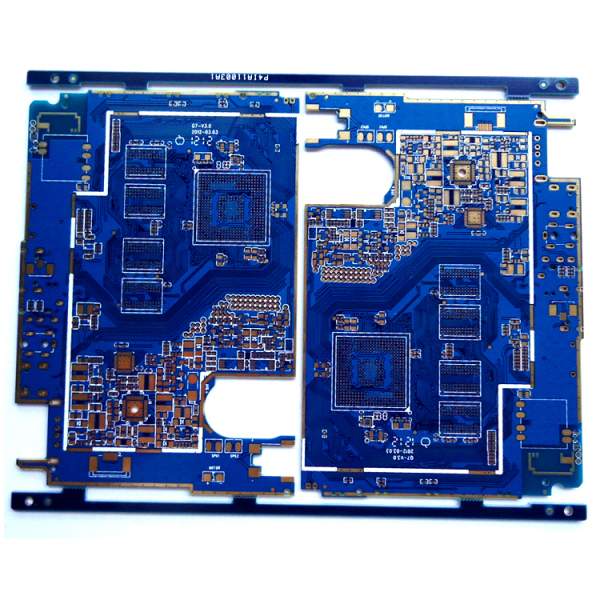

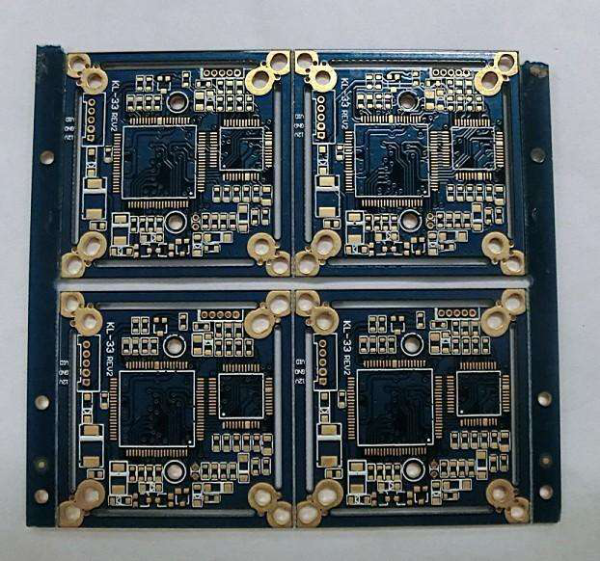

Ceramic PCB refers to a special process board in which copper foil is directly bonded to the surface (single-sided or double-sided) of alumina (Al2O3) or aluminum nitride (AlN) ceramic substrates at high temperatures. The made ultra-thin composite substrate has excellent electrical insulation properties, high thermal conductivity, excellent solderability and high adhesion strength, and can be etched into various patterns like a PCB board, and has a large current carrying capacity. ability. Therefore, Ceramic PCB has become the basic material of high-power power electronic circuit structure technology and interconnection technology.

Purpose

◆ High-power power semiconductor modules; semiconductor refrigerators, electronic heaters; power control circuits, power mixing circuits (high frequency mixing pressure plate).

◆Intelligent power components; high frequency (High frequency board) switching power supply, solid state relays.

◆Automotive electronics, aerospace and military electronic components.

◆Solar panel components; telecommunications dedicated switches, receiving systems; industrial electronics such as lasers.

Features

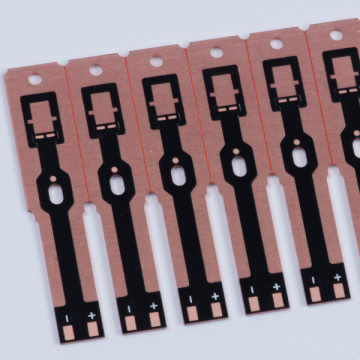

◆Strong mechanical stress, stable shape; high strength, high thermal conductivity, high insulation; strong bonding force, anti-corrosion.

◆ Excellent thermal cycling performance, with up to 50,000 cycles, high reliability.

◆Similar to PCB board (or IMS substrate), it can etch the structure of various patterns; it is pollution-free and pollution-free.

◆The operating temperature is wide -55℃~850℃; the thermal expansion coefficient is close to silicon, which simplifies the production process of power modules.

The advent of Ceramic PCB products has opened up the development of the heat dissipation application industry. Due to the characteristics of Ceramic PCB heat dissipation, and the advantages of Ceramic PCB, such as high heat dissipation, low thermal resistance, long life, and voltage resistance, with the improvement of production technology and equipment, product prices have accelerated and rationalized , And then expand the application areas of the LED industry, such as indicator lights for home appliances, car lights, street lights and outdoor large signs. The successful development of Ceramic PCB will provide services for indoor lighting and outdoor lighting products, and broaden the market for the LED industry in the future.

Related Keywords