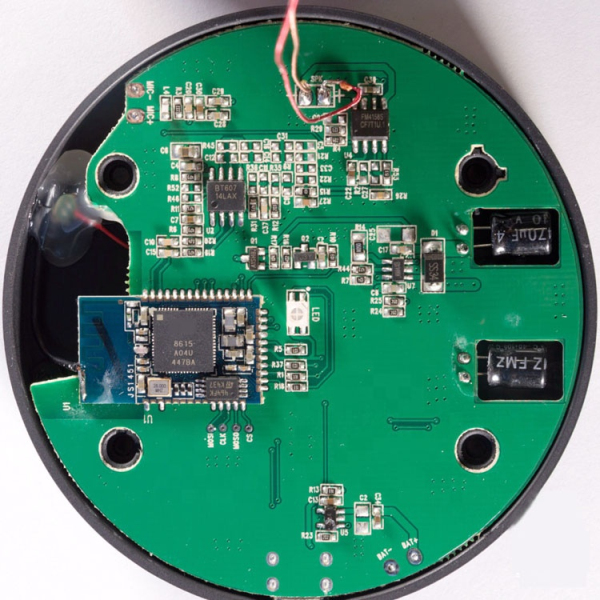

PCB Circuit Board PCB Assembly For Speaker

-

$1.87≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat can I use to clean the printed circuit board?

Nowadays, there are a lot of manufacturers producing circuit boards. There will be a mixture of fish and dragons. Impurities, dust, rosin, and solder will inevitably be produced on the surface of the circuit board during the production process. Before we leave the factory, we must clean the circuit board before leaving the factory, otherwise it will affect our factory. Quality and credibility. So the question is, in the face of producing thousands of circuit boards, such a huge quantity, how to clean the circuit boards to be clean?

In the past, my standard cleaning method was to use ordinary cotton swabs with 99% isopropyl alcohol. It can dissolve flux residues, but this cotton swab can easily trip over the sharp corners of the part, quickly turn into pieces, and leave tiny cotton fibers everywhere. Medidi sponge cotton swabs and cloth cotton swabs are used in the back. These cotton swabs are basically designed for industrial use. In any case, the packaging and winding of cotton are tighter than ordinary cotton swabs, and they are "low lint", and at the same time show superior abrasion resistance and cleanliness performance, and can be wiped repeatedly. It helps to reduce shreds and stray cotton fibers, but it cannot eliminate them completely.

As you can see here, isopropanol also leaves residues that look unattractive. Its visibility largely depends on the angle of light, and I deliberately chose the worst angle photo. I'm not sure if this residue really comes from alcohol, or if it is a residue dissolved in alcohol, but regardless of whether there are streaks on the PCB when it dries. I found that I need to wait until it dries, then use another dry cotton swab to wipe the dry area and remove the streaks. The final result is still not perfect, although it is very good. But the entire cleaning process can be very time-consuming, requiring several minutes for each circuit board.

Midi Di Di’s microfiber cotton swabs have been used in the back. This cotton swab sponge is more wear-resistant, scratch-resistant and dust-removing.

Why should the circuit board be cleaned after reflow soldering?

The cleaning of the circuit board after reflow soldering is very important, because all the solder materials that need to be cleaned are the solder containing more active agents, so the solder material will have better wettability and diffusibility, but there will be residues after reflow. Objects will corrode the substrate, so it needs to be cleaned.

Most of the cleaning methods are ultrasonic cleaning, but it may damage the electronic connectors. The reason is that the frequency is close or the same, which causes resonance and damages the resonance. At present, the crystal oscillators used in the industry mostly have a frequency of several thousand Hz, while the ultrasonic frequencies used by ultrasonic cleaners are basically several tens of thousand Hz. The frequency difference is an order of magnitude. Individual crystal oscillators with special frequencies need to be tested and verified. Whether it will have an adverse effect. Although it is a no-clean flux residue, there is still a high risk of "creep current" during use, which will cause product failure.

In addition, PCBA after no-clean flux soldering, a large part of which needs to be cleaned, is that the product needs to be coated for protection. Experiments have proved that if the flux residue is not thoroughly cleaned, and the coating is directly applied, after the temperature cycle, it will cause the coating film to crack. The reliability of the product is not as high as without coating.

Related Keywords