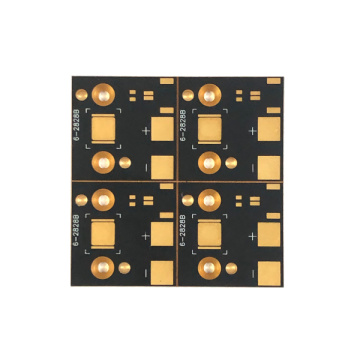

single sided Aluminum pcb quick turn service

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,L/C,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA |

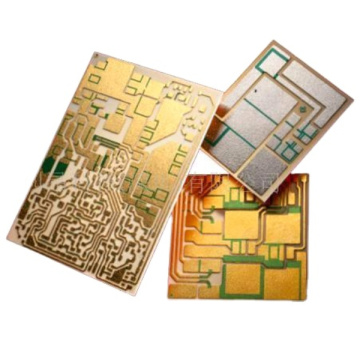

What aluminum PCB are widely use for?

Metal core PCBs can find their place in almost any application that generates a lot of heat when the device is running. These plates are not an ideal substitute for ceramics because they are a lower cost option, and they provide higher thermal conductivity to remove heat from important components. They are often a starting point when looking for circuit boards for systems with strong heat dissipation capabilities. Some applications of metal core PCB include:

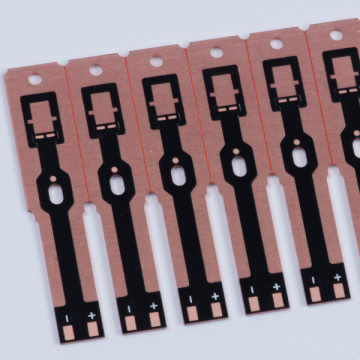

1.LED lighting unit: usually a board with high-power LEDs is manufactured on a metal core PCB. These boards provide a solid base for high-power LEDs (SMD and through-holes) while dissipating high heat into the metal core board.

2.Power conversion and management: Hybrid vehicles, industrial equipment, base station telecommunications equipment and municipal power distribution systems all operate at high power. In these fields, metal core PCBs are very common.

3.Solar energy equipment: Solar energy equipment needs to be particularly sturdy and run under high temperature and high DC voltage/current. Similar PCB designs can be implemented in geothermal facilities.

4.Military (for example, submersibles, airplanes): Metal core PCB can quickly dissipate heat, keeping electronics away from electronic equipment that may be located near high heat sources such as engines or exhaust systems.

In many other fields, high reliability and structural rigidity are also crucial, which makes metal core boards an excellent choice. Once you start to study the stacking and layout requirements of these boards, it becomes less obvious how to actually design them. Can a multilayer metal core board be made? Can it be double-sided? How to deal with vias in the manufacturing process? These are all important issues related to the DFM of metal core PCBs.

Related Keywords