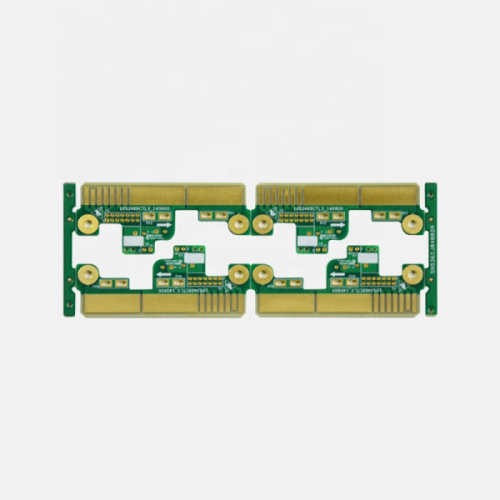

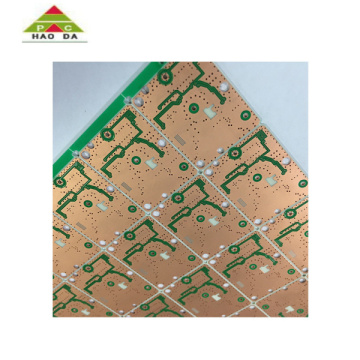

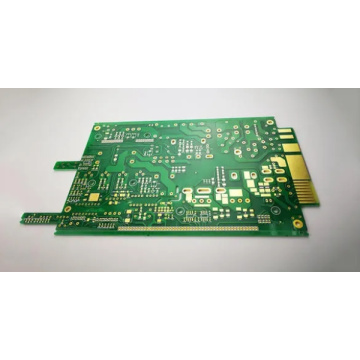

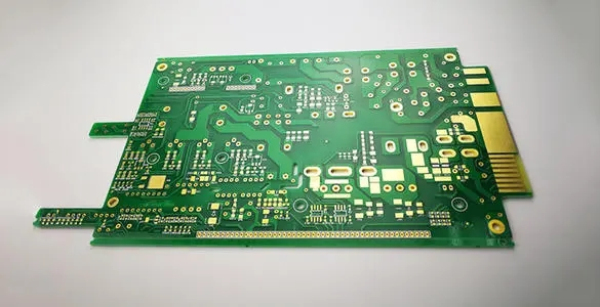

Multilayer PCB Fr4 PCB Immersion Gold PCB

-

$8.30≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal |

|---|---|

| Incoterm: | FOB,EXW |

Why do PCB circuit boards need immersion gold and gold plating?

The surface treatment processes of custom pcb fabrication include: anti-oxidation, tin spraying, lead-free spraying tin, immersion gold, immersion tin, immersion silver, hard gold plating, full board gold plating, gold finger, nickel palladium gold OSP, etc. The main requirements are: low cost pcb manufacturing, good weldability, harsh storage conditions, short time, environmentally friendly process, good welding, and flatness. Spray tin: The spray tin board is generally a multi-layer (4-46 layer) HDI PCB model, which has been adopted by many large domestic communication, computer, medical equipment and aerospace enterprises and research units.

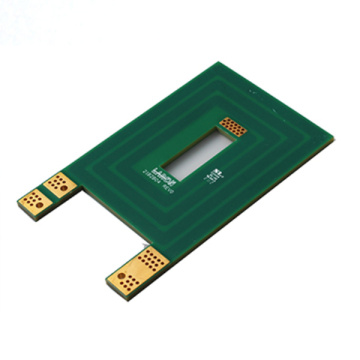

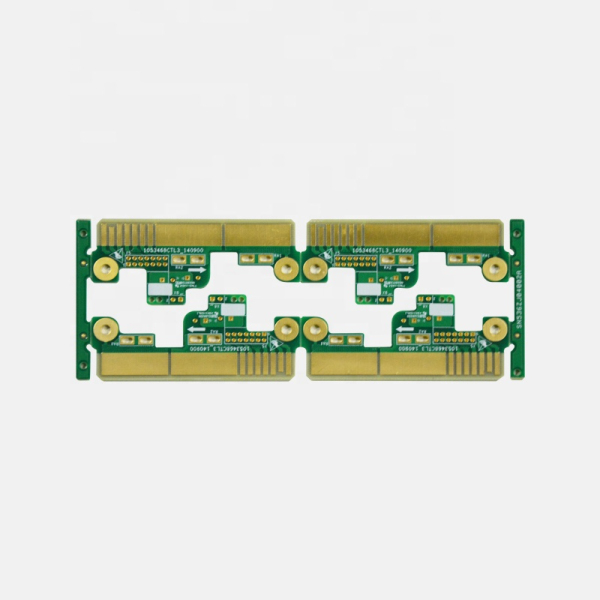

The connecting finger is the connecting part between the memory stick and the memory slot, and all signals are transmitted through the gold finger. The gold finger is composed of many golden conductive contacts. Because the surface is plated with gold and the conductive contacts are arranged like fingers, it is called "gold finger". The gold finger is actually covered with a layer of gold on the copper clad laminate through a special process, because gold has strong oxidation resistance and strong conductivity. However, due to the high price of gold, most memory is currently replaced by tin plating. Since the 1990s, tin materials have become popular. At present, the "gold fingers" of motherboards, memory and graphics cards are almost all used. Tin material, only some high-performance server/workstation accessories contact points will continue to use gold plating, which is naturally expensive.

The difference between gold plating and immersion gold process

Immersion gold adopts the method of chemical deposition. A layer of coating is formed by chemical redox reaction. Generally, the thickness is thicker.

Gold plating uses the principle of electrolysis, also known as electroplating. Most other metal surface treatments are also electroplated.

In actual product applications, 90% of gold plates are immersion gold plates, because the poor weldability of gold-plated plates is his fatal shortcoming, and it is also the direct reason why many companies give up the gold-plating process!

The immersion gold process deposits a nickel-gold coating with stable color, good brightness, smooth coating and good solderability on the surface of the printed circuit. Basically it can be divided into four stages: pre-treatment (oil removal, micro-etching, activation, post-dipping), nickel immersion, gold immersion, post-treatment (waste gold washing, DI washing, drying). The thickness of immersion gold is between 0.025-0.1um.

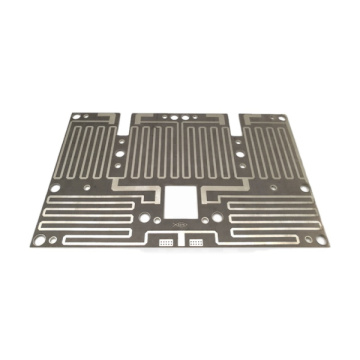

Gold is used in the surface treatment of circuit boards, because gold has strong conductivity, good oxidation resistance and long life, and is generally used in key boards, gold finger boards, etc. The most fundamental difference between gold-plated boards and immersion gold boards is that gold-plated is hard Gold (wear-resistant), immersion gold is soft gold (not wear-resistant).

1. The crystal structure formed by immersion gold and gold plating is different. The thickness of immersion gold is much thicker than that of gold plating. Immersion gold will be golden yellow, which is more yellow than gold plating (this is one of the methods to distinguish gold plating and immersion gold). a), the gold-plated ones will be slightly whitish (the color of nickel).

2. The crystal structure formed by immersion gold and gold plating is different. Compared with gold plating, immersion gold is easier to weld and will not cause poor welding. The stress of the immersion gold plate is easier to control, and for products with bonding, it is more conducive to the processing of bonding. At the same time, it is precisely because immersion gold is softer than gold plating, so the gold finger of immersion gold plate is not wear-resistant (the disadvantage of immersion gold plate).

3. The immersion gold board only has nickel-gold on the pad. The transmission of the signal in the skin effect is in the copper layer and will not affect the signal.

4. Compared with gold plating, immersion gold has a denser crystal structure and is not easy to produce oxidation.

5. With the increasing requirements of circuit board processing accuracy, the line width and spacing have reached below 0.1mm. Gold plating is prone to short circuit of gold wires. The immersion gold plate only has nickel gold on the pad, so it is not easy to produce a short circuit of gold wire.

6. The immersion gold board only has nickel-gold on the pad, so the combination of the solder mask on the circuit and the copper layer is stronger. The project will not affect the spacing when compensating.

7. For boards with higher requirements, the flatness requirements are better, and immersion gold is generally used, and the black pad phenomenon after assembly is generally not caused by immersion gold. The flatness and service life of the immersion gold plate are better than that of the gold-plated plate.

Why use Gold Plated

As the integration of originality electronics IC is getting higher and higher, the more and denser IC pins are. The vertical tin spray process is difficult to flatten the thin pads, which brings difficulties to the SMT placement; in addition, the shelf life of the tin spray board is very short. The gold-plated board just solves these problems: 1. For Surface-Mount (SMT) & BGA Assembly, especially for 0603 and 0402 ultra-small surface mounts, because the flatness of the pad is directly related to the quality of the solder paste printing process, for the subsequent The quality of reflow soldering plays a decisive role, so the whole board gold plating is often seen in high-density and ultra-small surface mount processes. 2. In the trial production stage, affected by factors such as component procurement, it is often not that the board will be soldered immediately, but often it will take several weeks or even a month to use it. The shelf life of the gold-plated board is longer than that of lead. Tin alloy is many times longer, so everyone is willing to use it. Besides, the cost of gold-plated PCB in the sample stage is almost the same as that of lead-tin alloy board. But as the wiring becomes denser, the line width and spacing have reached 3-4MIL. Therefore, the problem of short-circuiting of the gold wire is brought about: As the frequency of the signal becomes higher and higher, the transmission of the signal in the multi-layer coating caused by the skin effect has a more obvious influence on the signal quality. The skin effect refers to: high frequency alternating current, the current will tend to concentrate on the surface of the wire to flow. According to calculations, the skin depth is frequency dependent.

In order to solve the above problems of gold-plated boards, PCBs using immersion gold boards mainly have the following characteristics:

1. Because the crystal structure formed by immersion gold and gold plating is different, immersion gold will be more golden yellow than gold plating, and customers are more satisfied.

2. Because the crystal structures formed by immersion gold and gold plating are different, immersion gold is easier to weld than gold plating, and it will not cause poor welding and cause customer complaints.

3. Because the immersion gold board only has nickel gold on the pad, the transmission of the signal in the skin effect is in the copper layer and will not affect the signal.

4. Because immersion gold has a denser crystal structure than gold plating, it is not easy to produce oxidation.

5. Because the immersion gold plate only has nickel gold on the pad, it will not produce gold wire and cause slight short.

6. Since the immersion gold board only has nickel-gold on the pad, the combination of the solder mask on the line and the copper layer is stronger.

7. The project will not affect the spacing when making compensation.

8. Because the crystal structures formed by immersion gold and gold plating are different, the stress of the immersion gold plate is easier to control, and for products with bonding, it is more conducive to bonding processing. At the same time, it is precisely because immersion gold is softer than gold plating, so the gold finger of immersion gold plate is not wear-resistant.

9. The flatness and standby life of the immersion gold plate are as good as those of the gold-plated plate.

Therefore, most factories currently use the immersion gold process to produce gold plates. However, the immersion gold process is more expensive than the gold plating process (the gold content is higher), so there are still a large number of low-priced products that use the gold plating process (such as remote control boards, toy boards).

4. Immersion Gold Plate VS Gold Plated Plate In fact, the gold plating process is divided into two types: one is gold electroplating, the other is immersion gold

Here only for PCB problems, there are several reasons:

1. During PCB printing, whether there is an oil seepage film surface on the PAN position, it can block the effect of tin coating; this can be verified by a tin bleaching test.

2. Whether the moistening of the PAN bit meets the design requirements, that is, whether the pad design can sufficiently ensure the support of the parts.

3. Whether the pad is contaminated, which can be obtained by ion contamination test;

Related Keywords