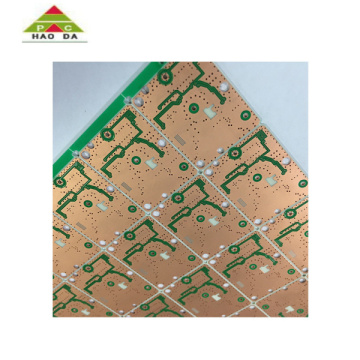

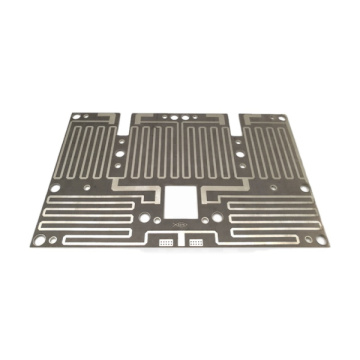

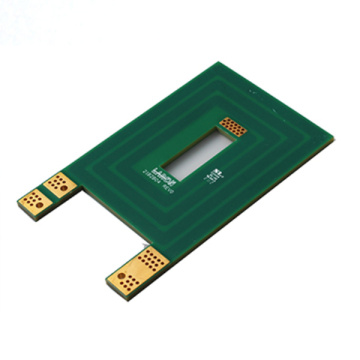

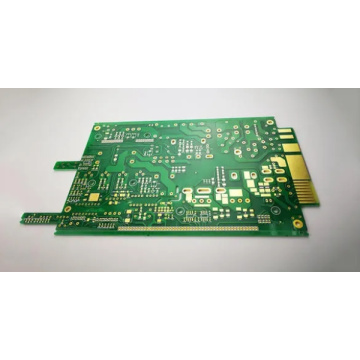

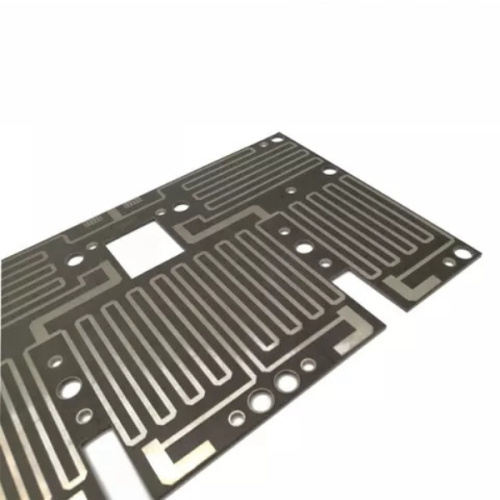

high frequency pcb laminate

-

$10.30≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

Which PCB laminate is used for higher frequency applications?

The PCB lamination process starts with choosing the right material. Choosing the right laminate is critical, because it determines the stability of the final assembly, lower losses and the best performance. There are several laminate options available to support PCB assembly.

1. FR4-This is the most commonly used laminate for surface mount assembly. It has a good strength-to-weight ratio and maintains excellent mechanical, electrical and physical properties at high temperatures. The material is also flame-retardant, increasing its reliability.

2. High Tg epoxy resin-this laminate is very suitable for multilayer PCBs. The material has excellent thermal properties and excellent chemical resistance. Provides excellent electrical insulation in applications with extreme humidity and temperature. Tg epoxy is very versatile, economical and flame retardant.

3. BT epoxy resin-BT epoxy resin is widely selected for its excellent thermal, mechanical and electrical properties. This laminate is suitable for lead-free PCB assembly. It is mainly used for multilayer board applications. It has excellent electromigration, insulation resistance and high heat resistance. It also maintains bond strength at high temperatures.

4. Polyimide-this material has excellent circuit trace bonding strength and extremely high environmental stability. Polyimide is ideally used to produce HDI PCB, flexible, Rigid-Flex Board and multilayer PCB. It has excellent thermal, chemical and mechanical properties, which makes it ideal for advanced applications in the military, aerospace, automotive and consumer electronics markets.

Among the above types, which one to choose to assemble PCB? There are several factors to consider. Some of these include:

Dielectric constant

Loss factor

Thermal Conductivity

Transition temperature

Coefficient of Thermal Expansion (CTE)

Electrical performance

Able to operate in a changing thermal environment

Related Keywords