Why is FR4 commonly used?

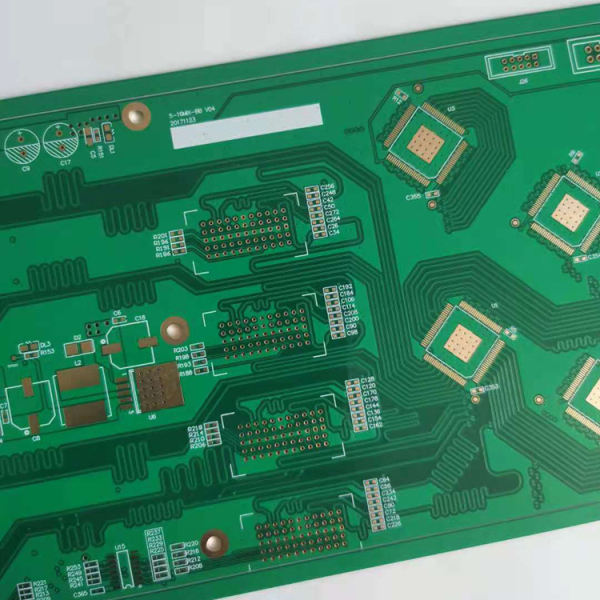

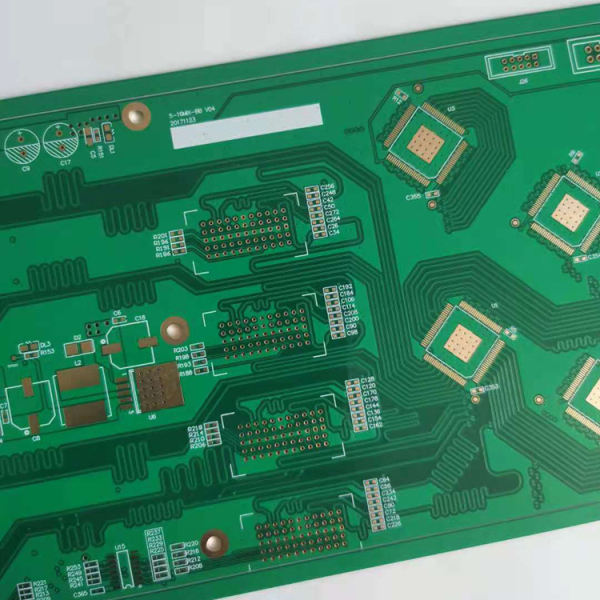

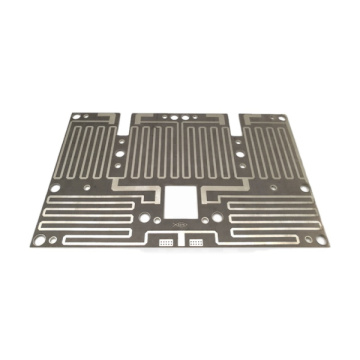

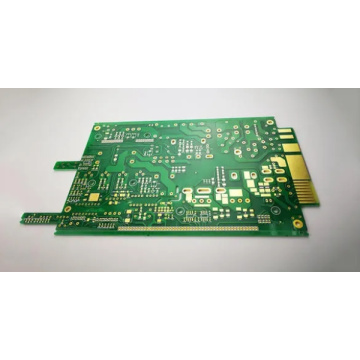

FR-4 material is the most successful and widely used material in PCB manufacturing for many years. This is mainly because FR4 substrates contain similar properties and most of them are epoxy resin systems, but this range is very wide. As a result, current FR4 materials are usually used in the most common terminals. For relatively simple applications, FR4 materials with a TG value of 130-140°C can be selected. For 0-18Layer FR4 boards or circuit boards with larger thickness, products that have relatively high requirements for heat resistance, FR4 materials with a TG value of 170-180 should be used. In the PCBA Manufacturing process, with the emergence of lead-free soldering processes, in addition to TG, TD and other indicators also need to be considered together. In addition, in lead-free soldering process applications, a higher TG value does not always mean better performance. In other words, with the expansion of end applications, the range of available FR4 materials will also expand.

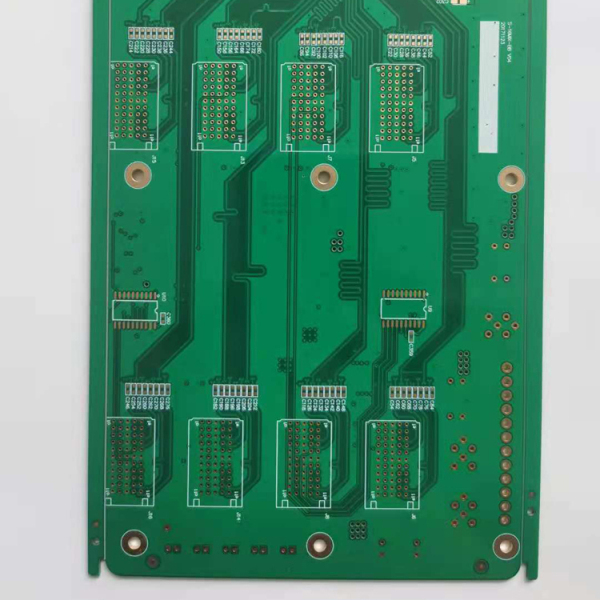

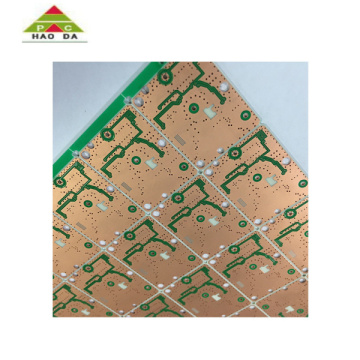

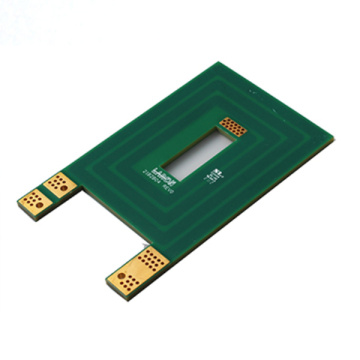

In addition, the components in FR4 materials, especially glass cloth and epoxy resin, make FR4 substrates a combination of good performance, processability and low cost materials, realizing low cost pcb manufacturing. Within the range of available glass cloth types, the thickness of the dielectric layer or the overall circuit board can be easily controlled. The diversity of epoxy resin makes it extremely easy to adjust the properties of the material to match the needs of the end application. It is precisely because epoxy resins have good electrical, thermal and mechanical properties that make them the most widely used resin type in PCBs. Compared with other types of materials, epoxy resin is easier to match the traditional PCB manufacturing process. Good manufacturability helps control the cost of FR4.

Finally, the development of FR4 materials makes full use of the perfect and mature manufacturing process and material system. The weaving process has been developed for many years. The process of weaving glass cloth yarn into glass cloth is basically not much different from the process of weaving yarn into textile fabrics. Using the same basic manufacturing technology can avoid additional preliminary research and development costs, but more importantly, it can avoid a certain degree of highly specialized fixed asset investment and help glass cloth suppliers reach a certain scale. As a result, the cost of these materials is well controlled. Similarly, epoxy resin has been used in other applications outside the scope of PCB, thus establishing a very large manufacturing basis for this type of material, which brings good competitiveness of cheap custom pcb fabrication to epoxy resin. In summary, FR4 basic type range, unique combination performance, processability and low cost features make it the main force of the PCB industry.