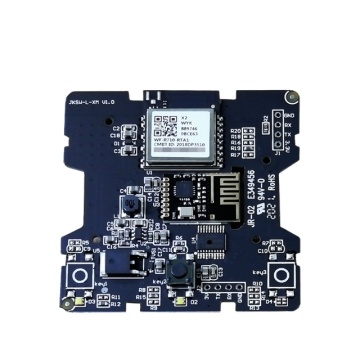

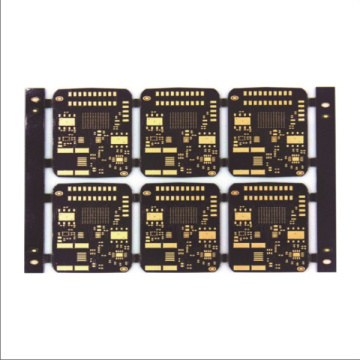

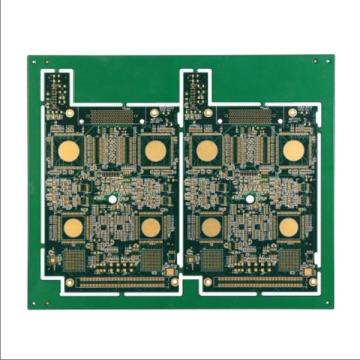

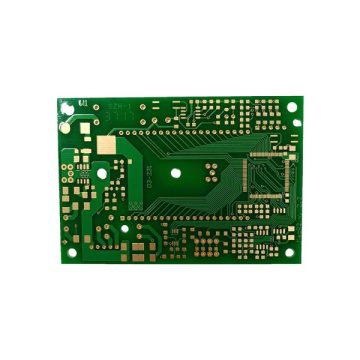

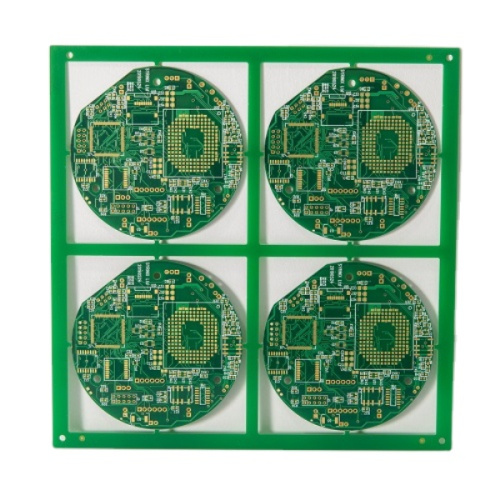

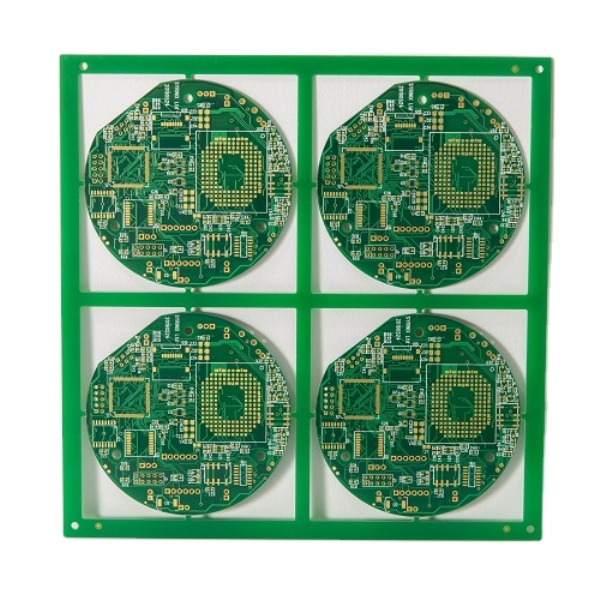

F4 BM350 high frequency board solar inverter pcb

-

$0.99≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is a high frequency PCB?

The high frequency PCB is as follows:

1. DK should be small and stable enough, usually the smaller the better, high DK may cause signal transmission delay.

2. DF should be small, which mainly affects the quality of signal transmission, and a smaller DF can reduce signal loss accordingly.

3. The coefficient of thermal expansion should be the same as the copper foil as much as possible, because the difference will cause the copper foil to separate when the heat and cold change.

4. In a humid environment, the water absorption rate must be low, and the water absorption rate is high, which will affect DK and DF.

5. Heat resistance, chemical resistance, impact resistance, and peel resistance must be good.

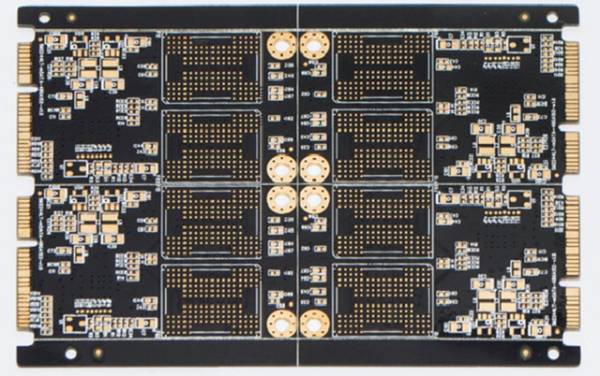

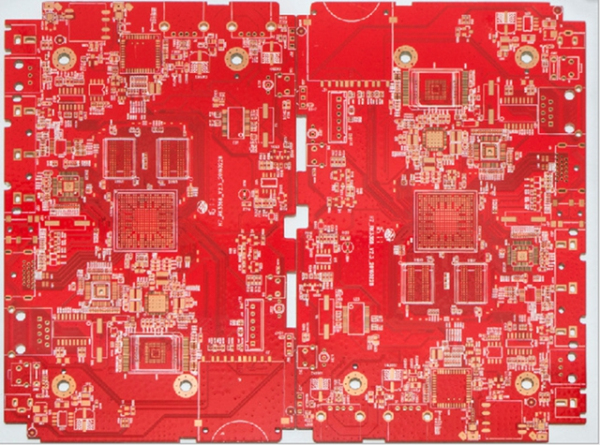

Generally speaking, high frequency can be defined as frequencies above 1 GHz. At present, polytetrafluoroethylene (PTFE) materials are widely used in high-frequency PCB manufacturing, also known as Teflon, whose frequency is usually higher than 5GHz. In addition, FR4 or PPO substrates can be used for product frequencies between 1 GHz and 10 GHz. The three high-frequency substrates have the following differences:

Regarding the lamination cost of FR4, PPO and Teflon, FR4 is the cheapest, while Teflon is the most expensive. In terms of DK, DF, water absorption and frequency characteristics, Teflon is the best. When the product application requires a frequency higher than 10GHz, we can only choose Teflon PCB substrate for manufacturing. Obviously, the performance of Teflon is far superior to other substrates, but Teflon substrates have the disadvantages of high cost and high heat resistance. In order to improve the rigidity and heat resistance of PTFE, a large amount of SiO2 or glass fiber is used as a filler. On the other hand, due to the molecular inertia of the PTFE material, it is not easy to bond with the copper foil, so special surface treatment is required on the combined side. Regarding the combined surface treatment, chemical etching or plasma etching is usually used on the PTFE surface to achieve surface roughness or an adhesive film is added between PTFE and copper foil, but these may affect the dielectric properties.

RF-RF PCB

Radio frequency (RF) and microwave (MW) circuits can be found in countless wireless products for medical and industrial handheld devices used in base stations, radars and advanced communication systems for global positioning. Microwave radio frequency board The success of these high-speed products begins at the product design stage of selecting PCB laminate materials. By providing information on material options, relative costs and DfM considerations, ensure that the project’s Low Cost Prototype PCB/performance goals are met. After the design is completed, RayMing will track the circuit board from prototype to production, measure and control key process variables, such as line width and dielectric spacing, to ensure that the product meets the design requirements and provides consistent performance throughout the product life cycle.

Related Keywords