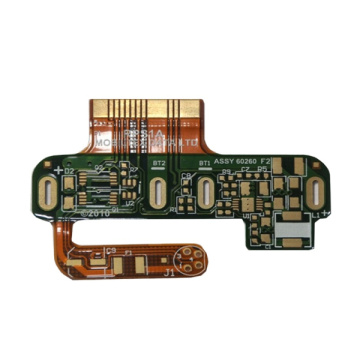

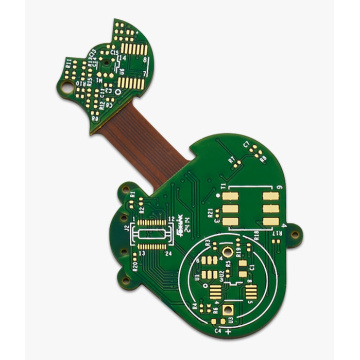

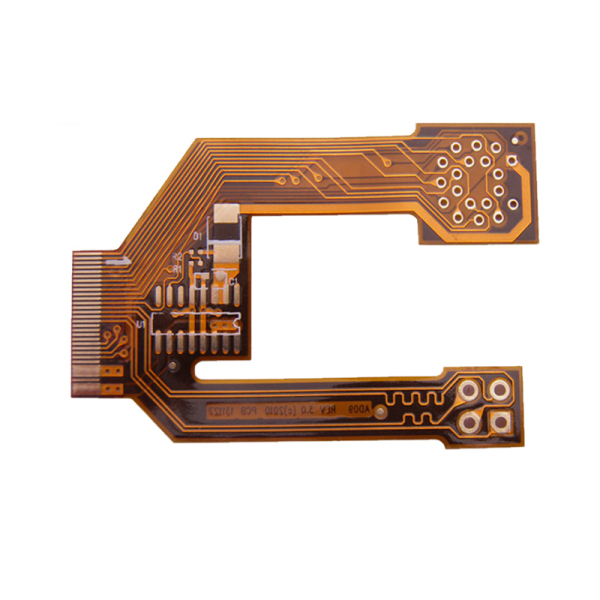

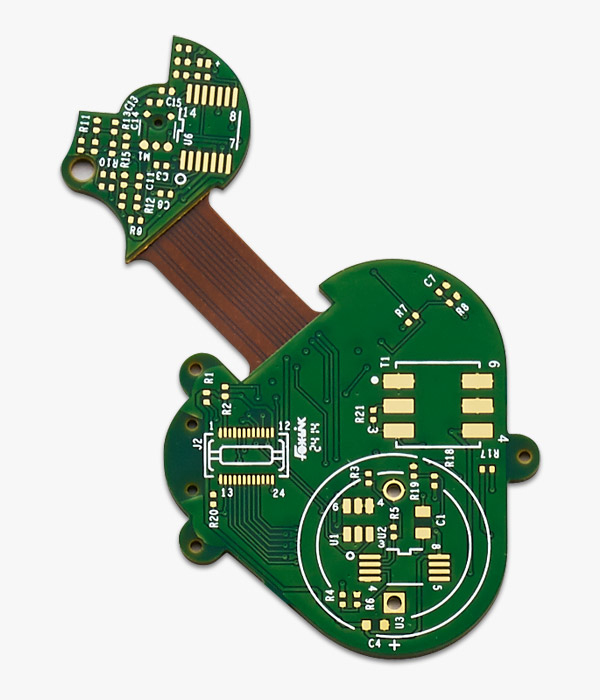

Flexible PCB with Board Thickness of 3.0mm

-

$6.10≥5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat are the advantages of flexible PCB?

Various electronic devices are becoming more and more important in our daily lives, ranging from mobile phones to computers. All kinds of electronic products have circuit boards, so there are many types of circuit boards.

What are the advantages of flexible PCB circuit boards

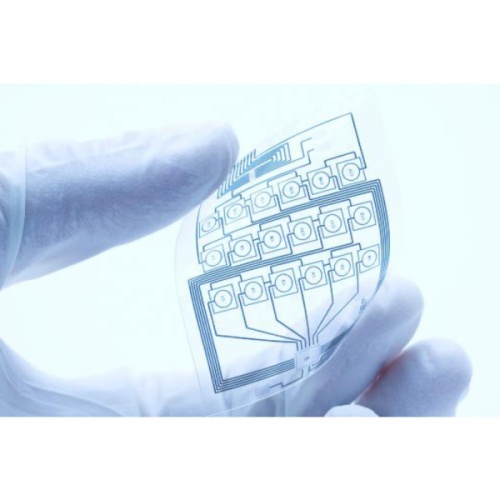

Most of these devices usually use printed circuit boards, because without it, most of these electronic devices will not work properly. There are several types of PCB, each with its own advantages. Flexible circuit boards are one of the most common circuit boards, and flexible PCBs have many benefits.

flexibility

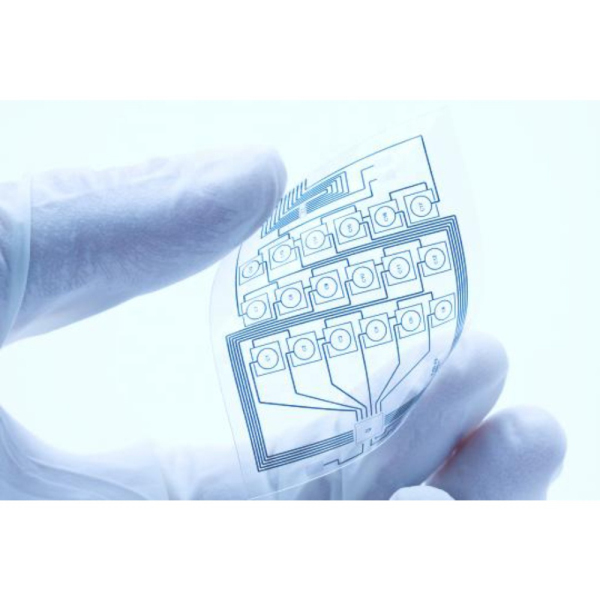

The main advantages of flexible circuit boards are their flexibility and bending capabilities. Therefore, they can be manipulated in various ways to fit the edges, folds and creases. The flexibility of the circuit board also means that it is more reliable and durable than ordinary PCB, because it can reduce the impact of vibration, and there are few wiring on the circuit board. Minimal wiring eliminates the need for Cable Connectors I/O Connectors, such as solder joints, contact crimping and Electronic connectors.

Reduce weight and space

Compared with other solutions, flexible printed circuit boards can not only provide greater design freedom, but also provide better space utilization and weight efficiency. The flexible printed circuit board is thin and light, which can greatly reduce weight and space. For smaller devices, these flexible plates can be folded, creased and placed in a smaller area to make the device miniaturized. This makes flexible circuit boards more suitable for small devices because they can be installed where rigid circuit boards cannot be mounted.

Flexible circuit boards can be made of various corrosion-resistant materials and can withstand harsh environments. These materials can be waterproof, shockproof, moisture-proof or even corrosion-resistant. Therefore, these flexible boards are widely used in military and medical applications due to their tough and durable qualities. The natural flexibility of the board can also better absorb shocks and shocks.

The flexible circuit board is made of polyimide, which has excellent thermal stability and can withstand extremely high heat. This also means that the improved heat dissipation performance makes the board a better basis for surface mounting and is less likely to undergo thermal expansion and contraction. The flexible board can also dissipate heat faster than other solutions, thereby increasing its thermal efficiency.

Flexible circuit boards can help reduce PCB assembly costs in many ways. The polyimide material of the PCB is thin and light, which means that it requires less space. Less space requirements mean the final assembly packaging size and the requirements of the mixed assembly material cost. Since the flexible board eliminates the need to route wires to solder joints and connectors, as the number of components required is reduced, assembly costs are further reduced. By reducing the number of components and wires on the board, testing and rework time can be reduced, thereby increasing productivity and efficiency.

Related Keywords