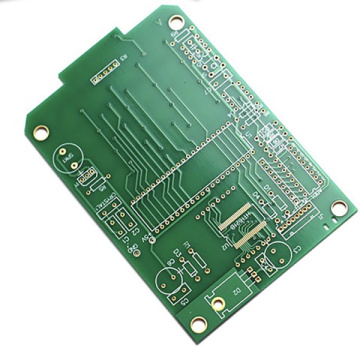

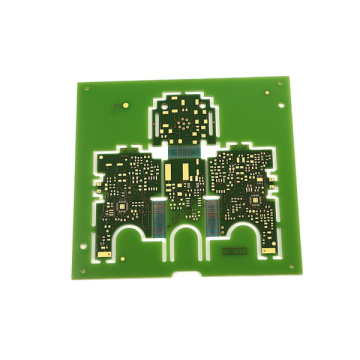

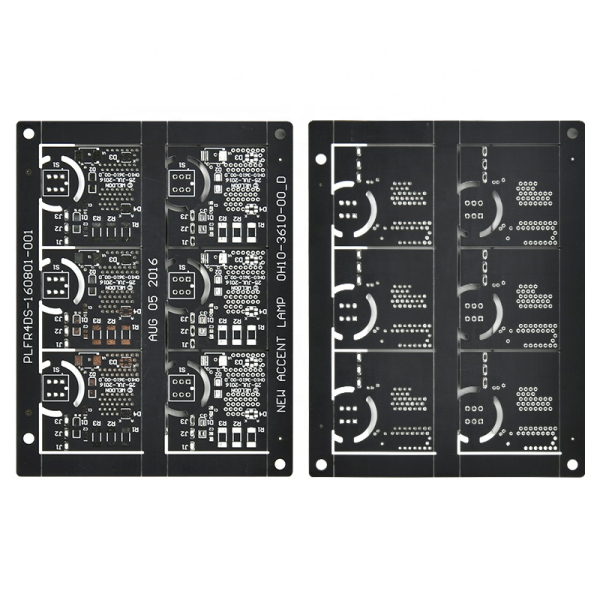

Electronic Circuit Board Through Hole PCB Assembly PCBA

-

$10.82≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

Does PCB thickness matter?

When I heard the word "standard", I thought of the benchmark that should be used to judge all other similar things. For example, Cadillac has long been regarded as the gold standard in automobiles. For many people, it still is. Now, standard can also refer to standard size. For example, the standard width of a sofa that can accommodate three people is 84 inches or 8 feet. When referring to product size, the standard may be very important because it may have attributes or functions that must be met.

For circuit boards, thickness is a very important criterion. Therefore, even if there is no single "official" standard, there are some common and preferred sizes. In some cases, your contract manufacturer (CM) may recommend that you comply with one of the following standards in order to tailor the functionality of your design equipment, custom pcb cost fabrication and/or Quick Turn PCB. Let us first look at the standard PCB thickness, and then discuss the issues that should be considered before choosing a non-standard or custom PCB thickness.

What is the standard PCB thickness?

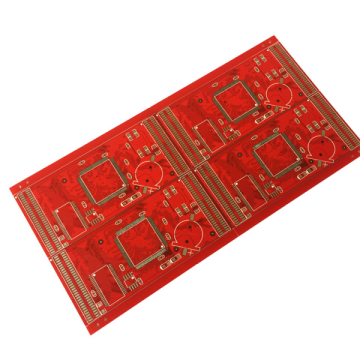

Many contract manufacturers may say that the standard PCB thickness is 1.57 mm, or about 0.062 inches. This is correct to a certain extent. Obviously, this is the size of the bakelite board manufactured in the early stage of circuit board manufacturing, and the size has been fixed. Therefore, we can call it the historical standard PCB thickness. Today, the size of circuit boards is larger or smaller than this standard, but this standard may still be the most common thickness in design.

Nowadays, it is more accurate to say that there are a series of common or standard PCB thicknesses. These include 0.031 inches (0.78 mm), 0.062 inches (1.57 mm) and 0.093 inches (2.36 mm). Depending on your PCB manufacturing options and assembly services, you may be able to manufacture circuit boards with other thicknesses. When determining PCB thickness, many of the following design and manufacturing factors need to be considered.

Design factors affecting PCB thickness

Copper thickness (heavy copper pcb)

Sheet

Quantity PCB layer

Signal type (Microwave radio frequency board)

Through-Hole Assembly (Through-Hole Assembly)

Operating environment

Manufacturing factors affecting PCB thickness

Drilling equipment

Copper thickness

Number of layers (0-18Layer FR4 board)

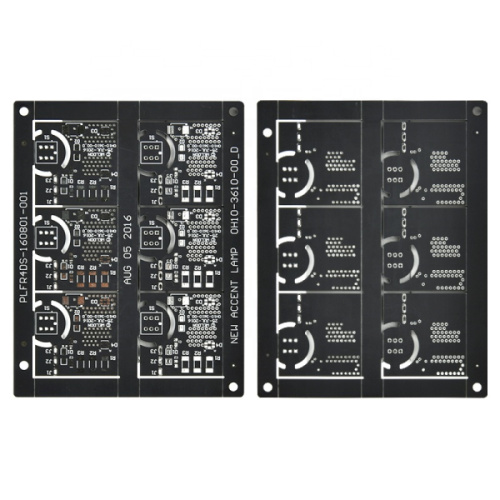

De-panelization method

PCBs are made of thin plates or panels and can be easily provided in common sizes. Your CM is more likely to own these stocks, or get them quickly. There may be other sizes, but they are limited by the processing capacity of the CM equipment, not to mention delays or delayed delivery times. Similarly, if your design requires unusual board thicknesses, you may be limited by the performance of the CM equipment and slowed down by the time required to purchase the boards or panels from the manufacturer. If you choose a custom PCB thickness, you should consider these factors as well as the other factors listed below.

Factor 1: CM's equipment function

The first thing to consider is whether your CM has the equipment to manufacture the required plate thickness. The determination should be made early in the design process, as required by the Design of Manufacturing (DFM). Otherwise, you may be forced to make modifications and redesign your PCB layout.

Factor 2: Extend the turnaround time

There is usually a delay in obtaining unusual PCB thicknesses. You should consider how this will affect your development quality and delivery schedule.

Factor 3: additional costs

Last but not least, you need to evaluate the additional costs incurred by special materials, manufacturing, and any lost man-hours to determine whether the additional costs are acceptable.

Related Keywords