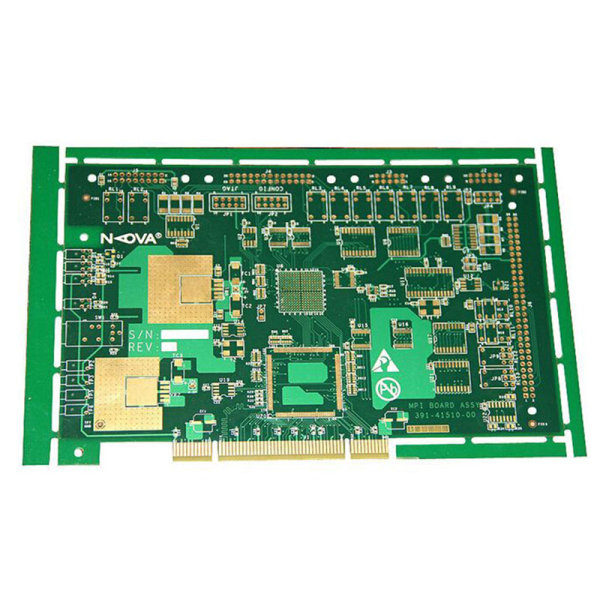

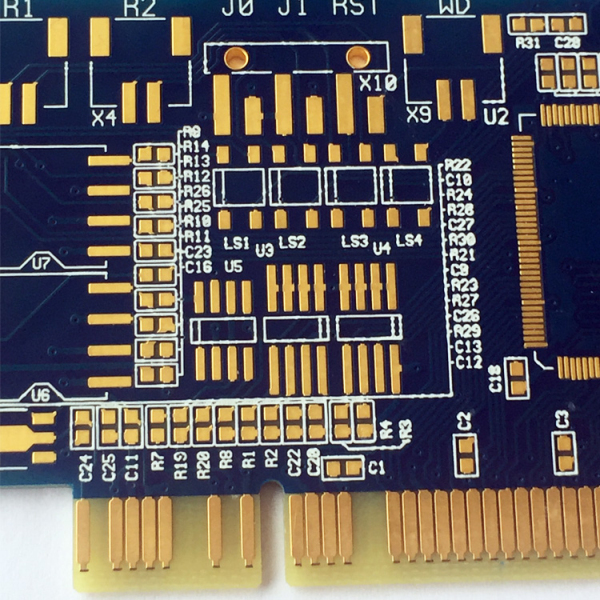

Electronics Multilayers Gold Finger PCB Board Manufacturing

-

$10.82≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

What is the golden finger in PCB?

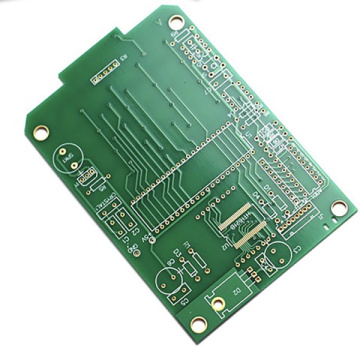

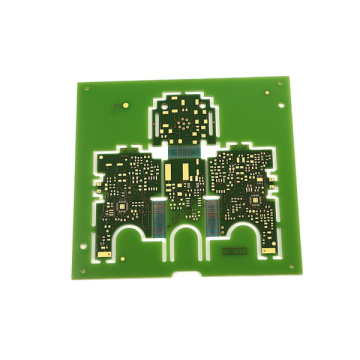

On computer memory sticks and graphics cards, we can see a row of golden conductive contacts, which are called "golden fingers". The Gold Finger (or Edge Connector) in the PCB design and production industry uses connector Electronic connectors to connect the board to the outside of the network, such as 6 layer Rigid-flex Immersion Gold PCB. In the production of High frequency board, in order to protect the connection port from oxidation, similar treatment is also carried out to ensure the use effect after PCB assembly. Rigid-Flex Board can also be treated in the same way. Next, let's understand how to deal with gold fingers in PCB and some details.

1. Electroplating nickel gold: thickness up to 3-50u", because of its superior conductivity, oxidation resistance and wear resistance, it is widely used in gold finger PCBs that require frequent insertion and removal or PCBA boards that require frequent mechanical friction. Above, but because of the extremely high cost of gold plating, it is only used for partial gold plating such as gold fingers.

2. Immersion gold: The thickness is conventional 1u", up to 3u" because of its superior conductivity, flatness and solderability, it is widely used in high-precision PCB boards with button positions, bonded IC, BGA, etc. Gold finger PCBs with low wear resistance requirements can also choose the entire board immersion gold process, which is much lower than the electro-gold process cost. The color of the Immersion Gold process is golden yellow.

Gold finger detail processing in PCB

1) In order to increase the wear resistance of the gold finger, the gold finger usually needs to be plated with hard gold.

2) Golden fingers need to be chamfered, usually 45°, other angles such as 20°, 30°, etc. If there is no chamfer in the design, there is a problem; the 45° chamfer in the PCB is shown in the figure below:

3) The gold finger needs to be treated as a whole piece of solder mask to open the window, and the PIN does not need to open the steel mesh;

4) Immersion tin and immersion silver pads need to be at a minimum distance of 14mil from the top of the finger; it is recommended that the pad be designed to be at least 1mm away from the finger, including via pads;

5) Do not cover the surface of the gold finger with copper;

6) All layers of the inner layer of the gold finger need to be cut copper, usually the width of the cut copper is 3mm larger; you can do half-finger cut copper and whole finger cut copper.

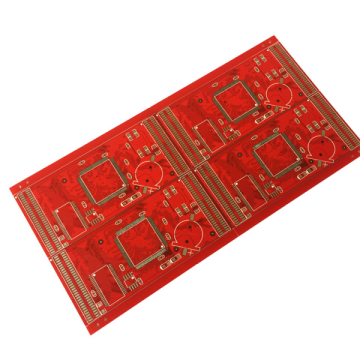

First, let's understand two concepts: soft gold and hard gold. Soft gold, generally soft gold. Hard gold is generally a compound of harder gold.

The main function of the golden finger is to connect, so it must have good electrical conductivity, wear resistance, oxidation resistance, and corrosion resistance.

Because the texture of pure gold (gold) is relatively soft, gold fingers generally do not use gold, but only a layer of "hard gold (gold compound)" is electroplated on it, which can not only obtain good electrical conductivity of gold, but also make it resistant Abrasion performance, anti-oxidation performance.

Then, has the PCB used "soft gold"? The answer is of course there is use, such as the contact surface of some mobile phone buttons, COB (Chip On Board) with aluminum wire and so on. The use of soft gold is generally to deposit nickel gold on the circuit board by electroplating, and its thickness control is more flexible.

Related Keywords