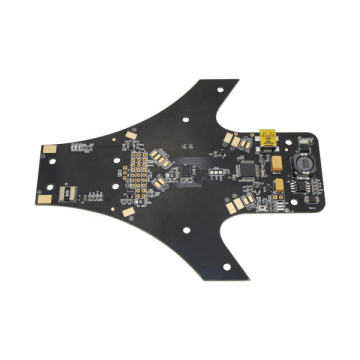

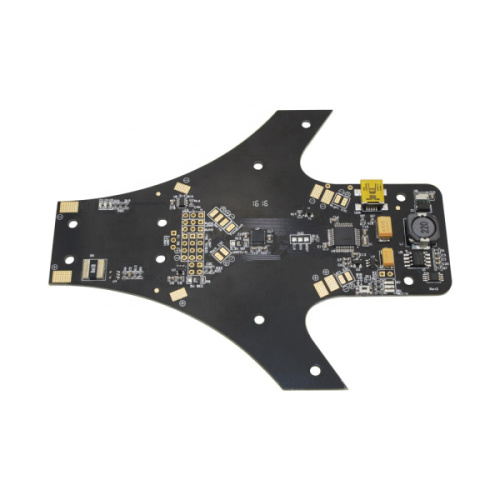

Fr4 8 Layer Communication Pcb

-

$0.95≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal |

|---|---|

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air,Express |

Is the black PCB good?

PCB, as the supporting body of hardware Electronic Components, is found in almost any hardware product. Inside the exquisite product shell, it always silently carries the flow of various information with its hard body.

Since the iPhone era, almost all black PCB circuit boards have been used. What prompted this change? What is special about the black circuit board?

Statement 1: In the process of PCB washing, black is the most likely to cause chromatic aberration. If the raw materials used by the PCB factory and the self-made process are slightly different, the PCB defect rate will increase due to the chromatic aberration.

Zun: First of all, I have never touched the factory to tell me the problem of color difference. Chromatic aberration is not an item assessed by customers, and it is difficult to quantify. In addition, compared with black, other colors are more likely to cause chromatic aberration. Because there is one kind of black, as much black as possible is enough, and there are many other colors.

Statement 2: As the circuit traces of the black PCB are illegible, it will increase the difficulty of repair and debugging in the R&D and after-sales stages. Generally, if there is no brand with profound RD (R&D) designers and a strong maintenance team, it will not be easy Use black PCB.

Zun: This statement is nothing short of serious nonsense, and it makes sense.

First of all, there are drawings for Debug, and the circuit developed by myself. When debugging, you can read the drawings if you can’t see clearly. Besides, whoever finds a signal can find it entirely on the PCB board.

Xian: The circuit designer will not be cheap. It will not increase maintenance costs just to pretend to be a force. There are tools for maintenance, not by eyes. I can see where there is a problem with the circuit with my eyes, and I sent it to the Chinese Academy of Sciences as a research object. In general, the masters in the electronics market use modular replacements. Even if the chips are changed, they will not observe the PCB traces, mainly relying on tools and experience.

Do you confirm the green board and find the line with the naked eye?

Statement 4: To prevent plagiarism

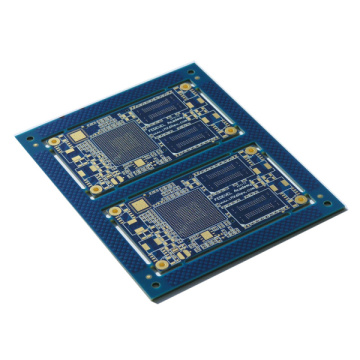

Yu: Brother, have you made 4-layer, 6-layer, 8-layer, and 20-layer boards? Even if it is made green, do you see the line with your eyes?

Do you know a multimeter?

Statement 5: Good heat dissipation? The reason why black oil is used is actually because black oil dissipates heat better than any other color oil. Everyone only knows that black objects absorb heat better. In fact, from the theory of heat radiation, heat dissipation is the same as heat absorption. The darker the color and the rougher the surface, the better the heat radiation, so many heat sinks are made black. This is the reason that refrigerator condensers and compressors are all black.

Yu: Black is good for heat dissipation, but your PCB itself is so hot, your design is enough.

According to the classic radiation law of physics-the radiation power of all objects is equal to its absorption power, and the absorption power of a non-black body is always less than that of a black body at the same temperature. Therefore, comparing the heat dissipation capacity of non-black objects with black objects under the same conditions, black objects dissipate heat significantly faster, and the darker the color, the higher the emissivity and absorption rate of heat energy.

If your PCB needs to dissipate heat, it will brighten copper and use aluminum substrates. These are not black. In fact, the color is negligible compared to the measures of other dimensions.

If the MOSFET needs good heat dissipation, the pad on the front side will be enlarged and the solder mask on the back side will be removed.

1. The cost of black PCB is indeed more expensive than the cost of green. Some manufacturers charge a fee for color.

There are two reasons:

① There are more users who choose green, so green is relatively cheap, so some fees will be charged for other colors.

② All boards with black solder mask in batches need to be tested! It is more difficult to find the problem because of the visual inspection of the surface processing errors.

During the PCB assembly process (pcb assembly), there is visual inspection (visual inspection), and human vision is prone to visual fatigue to yellow, red and black. Let you test 6000 pcs black pcba on Foxconn assembly line 12 hours a day.

It is said that there is no visual inspection of the Apple production line (to be verified), and it should mainly rely on automatic optical inspection machine (AOI) and non-destructive flaw detector (X-Ray)

2. Because we are accustomed to green PCBs, we chose green paint as the material for PCB solder mask because of a coincidence. But if 90% of the PCBs in the world are black, people will think that black is so ugly, but green is taller.

It is estimated that Jobs's strong obsessive-compulsive disorder just likes the strong contrast between black and bright gold of the pad, so he chooses black uniformly. In fact, the iPod has always been green.

The use of black pcb has nothing to do with high-end, it is just a style of designer.

These telecommunications blade servers are priced at tens of thousands or even hundreds of thousands, and they are often green.

3. The black PCB is not easy to be found inside the product. This is a fact, if you are particularly concerned about this, let's just make an excuse.

Related Keywords